13

01

Operating the Zero Turn Rider

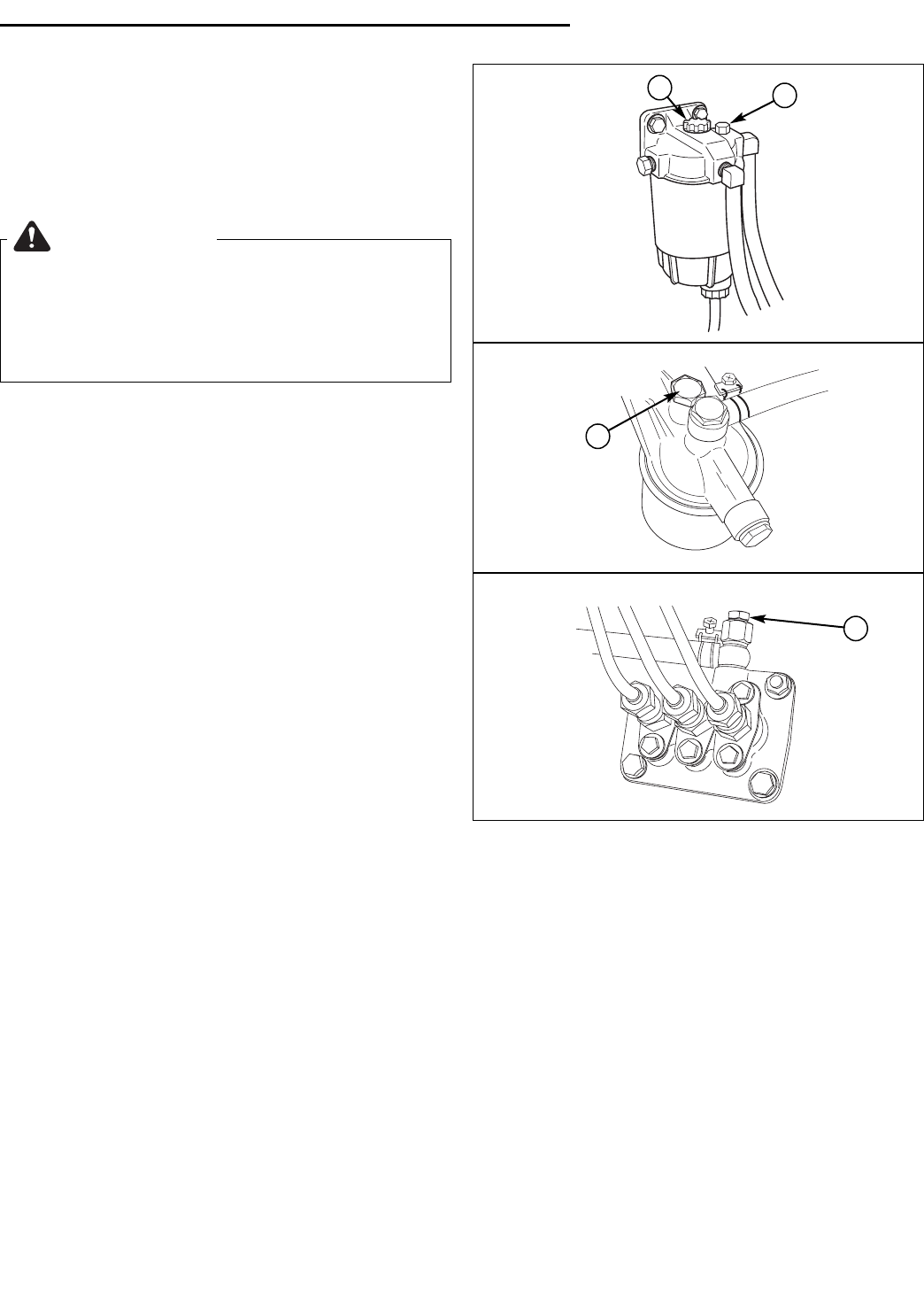

PRIMING THE FUEL SYSTEM

Diesel Model Only

Priming the fuel system fills the fuel filters and removes

any air bubbles from the fuel system. This must be per-

formed before the first use, after any fuel filter mainte-

nance or if the fuel system is run dry.

To prime the fuel system:

On the water separator:

1. Using a 1/2” wrench, loosen the vent screw on the

water separator 2-3 revolutions.

2. Unscrew the priming hand pump (B, Figure 5) locat-

ed on top of the water separator. Operate the hand

pump up and down until fuel that is free of air flows

from the vent.

3. Tighten the vent screw to 4.5 ft/lbs (6 N.m.). DO

NOT OVER TIGHTEN!

On the engine fuel filter:

1. Using the appropriate size wrench, loosen the vent

screw on the engine fuel filter 2-3 revolutions.

2. Operate the hand pump up and down until fuel that

is free of air flows from the vent.

3. Tighten the vent screw to 4.5 ft/lbs (6 N.m.). DO

NOT OVER TIGHTEN!

On the engine injector pump:

1. Using a 13mm wrench, loosen the vent screw on the

fuel inlet 2-3 revolutions.

2. Operate the hand pump up and down until fuel that

is free of air flows from the vent.

3. Tighten the vent screw to 4.5 ft/lbs (6 N.m.). DO

NOT OVER TIGHTEN!

4. Tighten the priming fuel pump finger tight.

5. Start the engine. (See STARTING THE ENGINE). If

the engine will not start, further priming is necessary.

If the engine starts but misfires or continues to emit

smoke, further priming is necessary.

6. If the engine starts but runs rough, continue to run

the engine at low idle until the engine runs smoothly.

Figure 5. Fuel System Priming

A. Water Separator Vent Screw

B. Priming Hand Pump

C. Engine Fuel Filter Vent Screw

D. Injector Pump Vent Screw

A

WARNING

Fuel leaked or spilled onto hot surfaces or

electrical components can cause a fire. To help

prevent possible injury, turn the ignition switch

off when changing fuel filter or water separator

element. Clean up fuel spills immediately.

B

C

D