Maintenance

Adjustments

Note: Disengage PTO, shut off engine, wait for

all moving parts to stop, engage parking brake, and

remove key before servicing, cleaning, or making any

adjustments to the unit.

Deck Leveling

1. Position mower on a at surface.

2. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

3. Check tire pressure in drive tires. Proper ination

pressure for tires is 13 psi (90 kPa). Adjust if

necessary. Semi-pneumatic caster tires Do Not

need to be inated.

4. Set anti-scalp rollers to top holes (if installed) or

remove them completely for this adjustment.

5. Lower the deck to the 1 1/2 inch (3.8 cm) height

position. Place two 1 1/8 inch (2.9 cm) thick

blocks under the rear edge of the cutting deck

skirt; one on each side of the cutting deck.

6. Place a 1 inch (2.5 cm) block under the center

front edge, but not under the anti-scalp roller

brackets.

7. Loosen the four bottom chain bolts in slots until

the deck is supported by the blocks. Take the

slack out of the chains and retighten the hardware.

8. Recheck that blocks t just snugly under the

deck skirt and that the tension on all the chains

is approximately equal. Make sure all chain

attachment bolts are tight.

9. Reposition anti-scalp rollers (if installed) and

tighten securely.

Note: When above adjustments have been made,

the front of the deck will be slightly lower than the

rear of the deck.

Pump Drive Belt Tension

Self-tensioning - No adjustment necessary.

Deck Drive Belt Tension

Self-tensioning – No adjustment necessary.

Electric Clutch Adjustment

No adjustment necessary.

Motion Control Linkage

Adjustment

Note: There are two lever height options available.

Place the levers in the top two holes to increase

height of the levers, or in the bottom two holes to

decrease the height of the levers.

1. Align the levers front/rear position. With the

levers in the neutral position, loosen the hardware

and adjust the levers sliding and/or tilting the

lever(s) forward or backward until properly

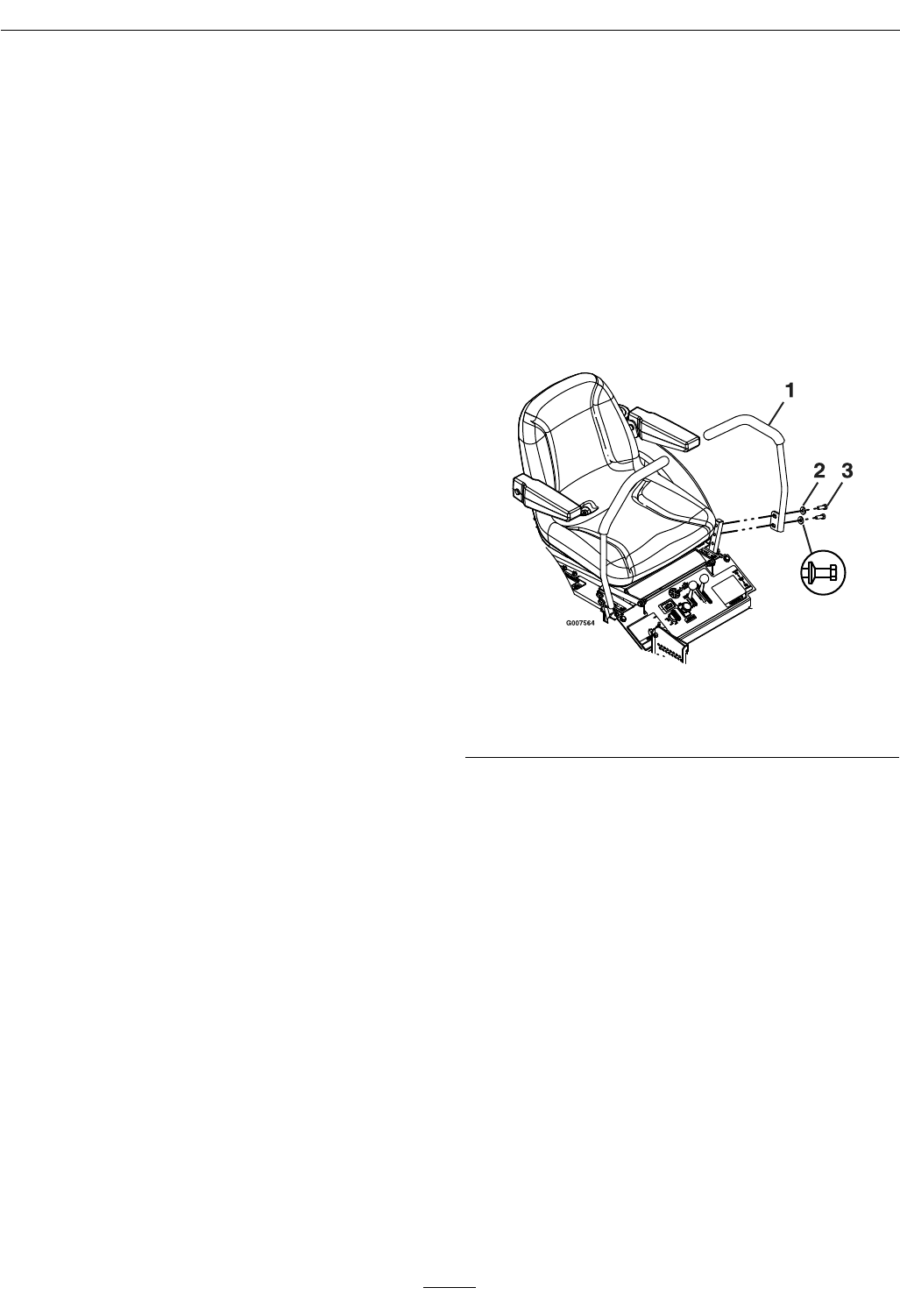

aligned and tighten hardware (Figure 11).

Figure 11

1. Motion control levers

3. 3/8-16 x 1 inch screw

2. Spring disc washer

2. If the ends of the levers hit against each other,

while in the drive position (levers rotated in as

far as possible), make adjustments by moving the

levers outwards to the neutral lock position and

carefully bending them outward. Move them back

to the drive position and check for clearance.

Repeat if necessary.

3. If the machine turns right or left when handles are

pushed forward together, adjust the stop on the

side opposite the direction of turn (see Figure 12).

Move the stop back until the unit drives straight.

Readjust handles if necessary.

28