Maintenance

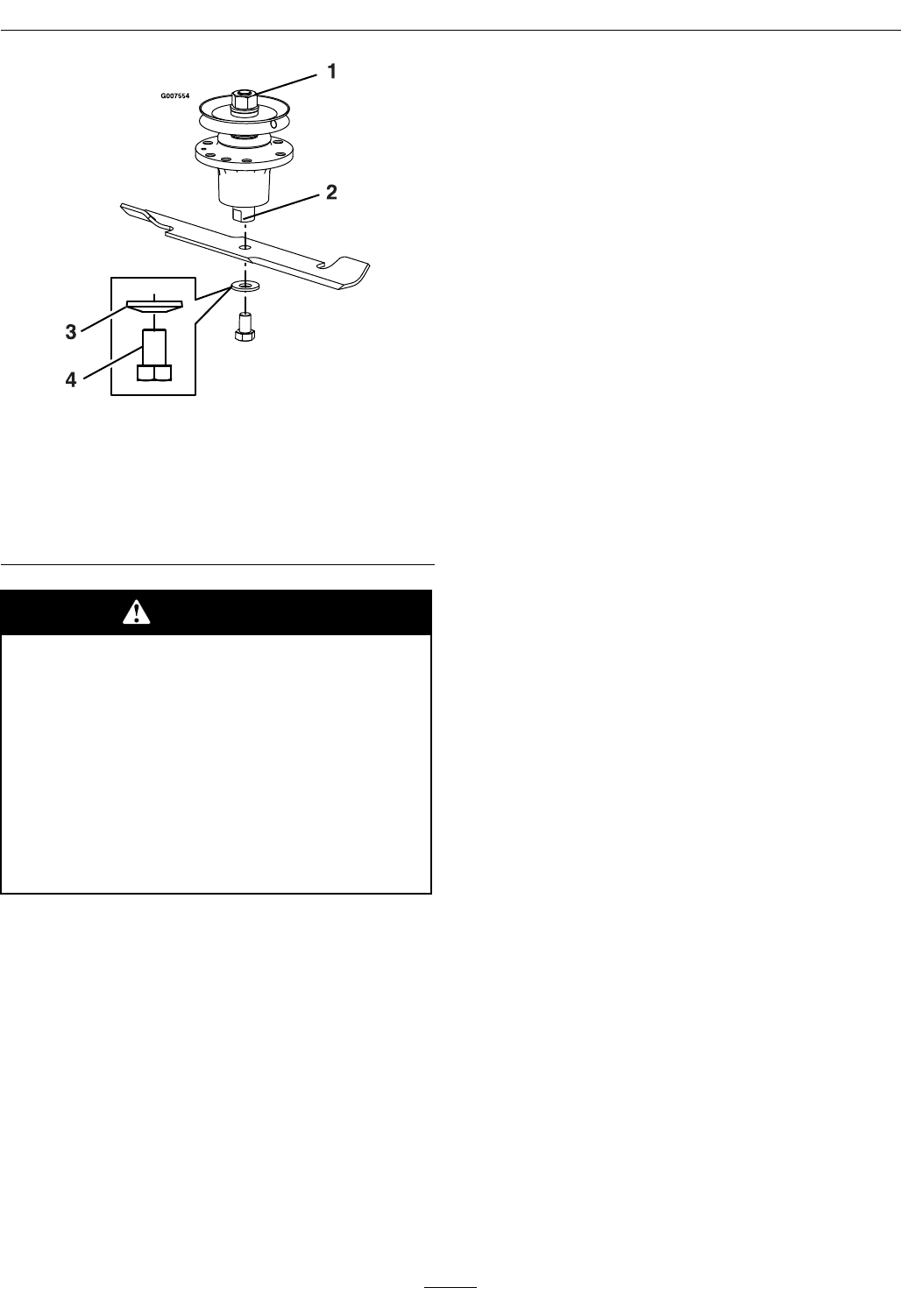

Figure 8

1. Do Not use wrench here for blade installation. Maintain

140–145 ft-lb (190–197 N-m)

2. Use 1 inch wrench here to hold spindle for blade

replacement.

3. Cone towards bolt head

4. Torque to 115–120 ft-lb (156–163 N-m)

WARNING

Incorrect installation of the blade or

components used to retain the blade can

be dangerous. Failure to use all original

components and assembled as shown could

allow a blade or blade component to be

thrown out from under the deck resulting in

serious personal injury or death.

Always install the original Exmark blades,

spring disc washers, and blade bolts as

shown.

Check Safety Interlock

System

Service Interval: Before each use or daily

Note: To prevent engine cut-outs on rough terrain

the seat kill switch has a 1/2 second delay.

1. Check starting circuit. Starter should crank with,

parking brake engaged, PTO disengaged and

motion control levers moved out in the neutral

lock position. The operator does not need to be

in the seat to start the engine.

Try to start with operator in seat, parking brake

disengaged, PTO disengaged and motion control

levers in the neutral lock position - starter must

not crank.

Try to start with operator in seat, parking brake

engaged, PTO engaged and motion control

levers in the neutral lock position - starter must

not crank.

Try to start with operator in seat, parking

brake engaged, PTO disengaged, and the left

motion control lever in, starter must not crank,

repeat again with the right lever in, then with

both levers in - starter must not crank.

2. Check the kill circuits. Run engine at one-third

throttle, disengage parking brake and raise off

of seat (but do not get off of machine) engine

must initiate shutdown after approximately 1/2

second has elapsed (seat has time delay kill switch

to prevent cut-outs on rough terrain).

Run engine at one-third throttle, engage PTO

and raise off of seat (but do not get off of

machine) engine must initiate shutdown after

1/2 second has elapsed.

Run engine at one-third throttle, with brake

disengaged, move levers in and raise off seat (but

do not get off of machine) engine must initiate

shutdown after 1/2 second has elapsed.

Again, run engine at one-third throttle, brake

engaged, and move left motion control lever in

- engine must initiate shutdown.

Repeat again moving the right lever in, then

moving both levers in - engine must initiate

shutdown whether operator is on seat or not.

Note: If machine does not pass any of these tests,

Do Not operate. Contact your authorized EXMARK

SERVICE DEALER.

Important: It is essential that operator safety

mechanisms be connected and in proper

operating condition prior to use for mowing.

Check for Loose Hardware

Service Interval: Before each use or daily

23