14

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

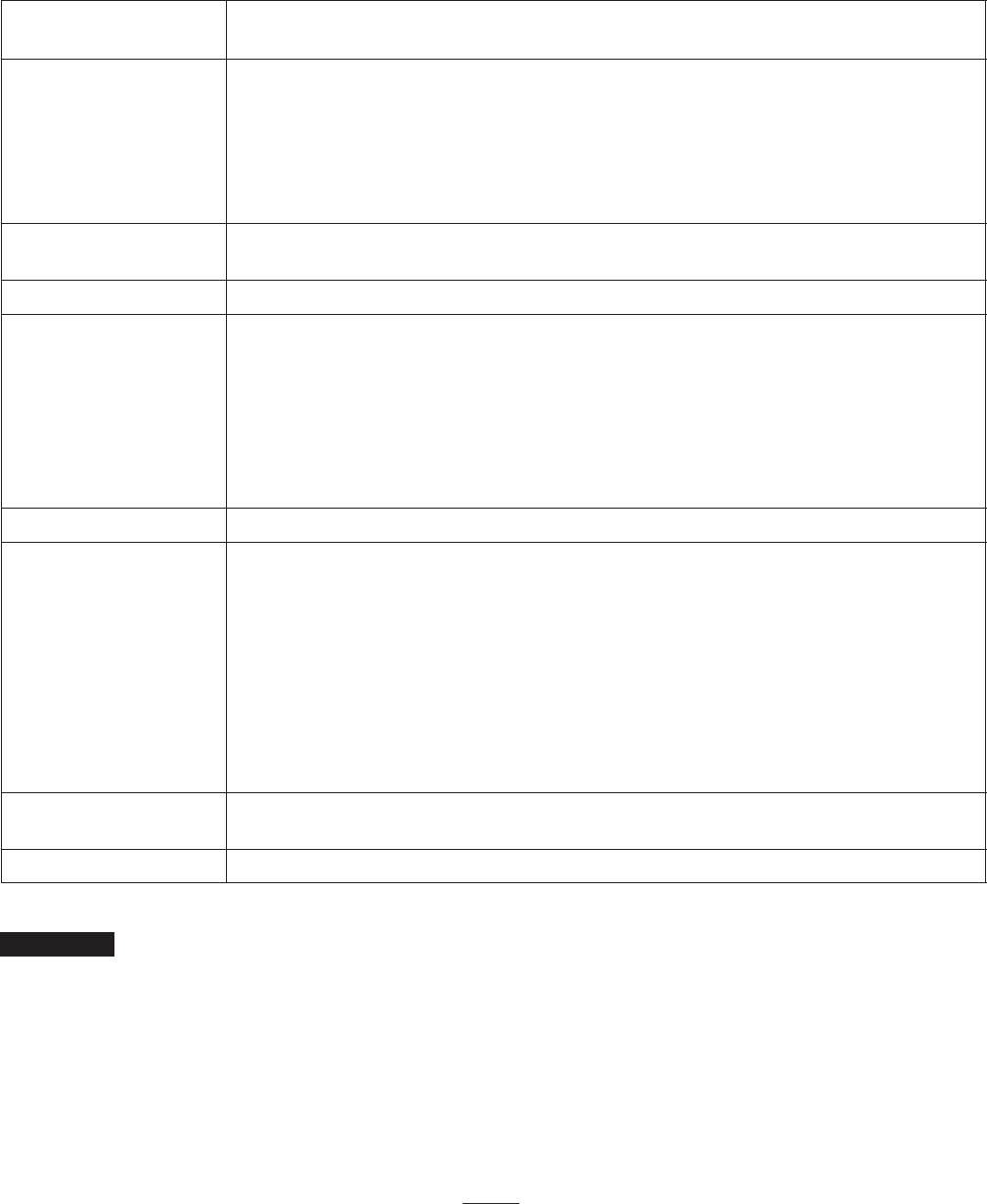

Recommended Maintenance Schedule

Maintenance Service

Interval

Maintenance Procedure

Each Use

• Check the engine oil level.

• Check the stopping time of the blade brake. The blade must stop within

3 seconds of releasing the bail; if it does not, contact an Authorized Service

Dealer for repair.

• Remove grass clippings and dirt from under the housing.

• Clean the discharge tunnel and the discharge tunnel plug.

5 Hours

• Check the blade and the engine mounting fasteners. Tighten them if they are

loose.

25 Hours • Clean the foam pre-cleaner of the air cleaner.

50 Hours

• Change the engine oil (without the oil filter).

1

• Sharpen or replace the blade; maintain it more frequently if the edge dulls

quickly in rough or in sandy conditions.

• Check for leaks in the fuel system and/or a deteriorating fuel hose. Replace

parts if necessary.

• Remove grass clippings and debris from under the belt cover.

• Lubricate the pivot arms (self-propel model only).

75 Hours • Adjust the self-propel drive system (self-propel model only).

100 Hours

• Change the oil filter.

• Inspect the spark plug and replace it if necessary.

• Clean the cooling system; remove grass clippings, debris, or dirt from the engine

air cooling fins and starter. Clean the system more frequently in dirty or

high-chaff conditions.

• Clean the fuel filter.

• Lubricate the gear case.

• Adjust the blade brake cable.

• Service the wheels.

300 Hours

• Replace the paper air filter. Replace it more frequently in dusty operating

conditions.

Storage • Empty the fuel tank before repairs as directed or before storage.

1

Change the engine oil after the first 8 operating hours.

Important Refer to your engine operator’s manual for additional maintenance procedures.