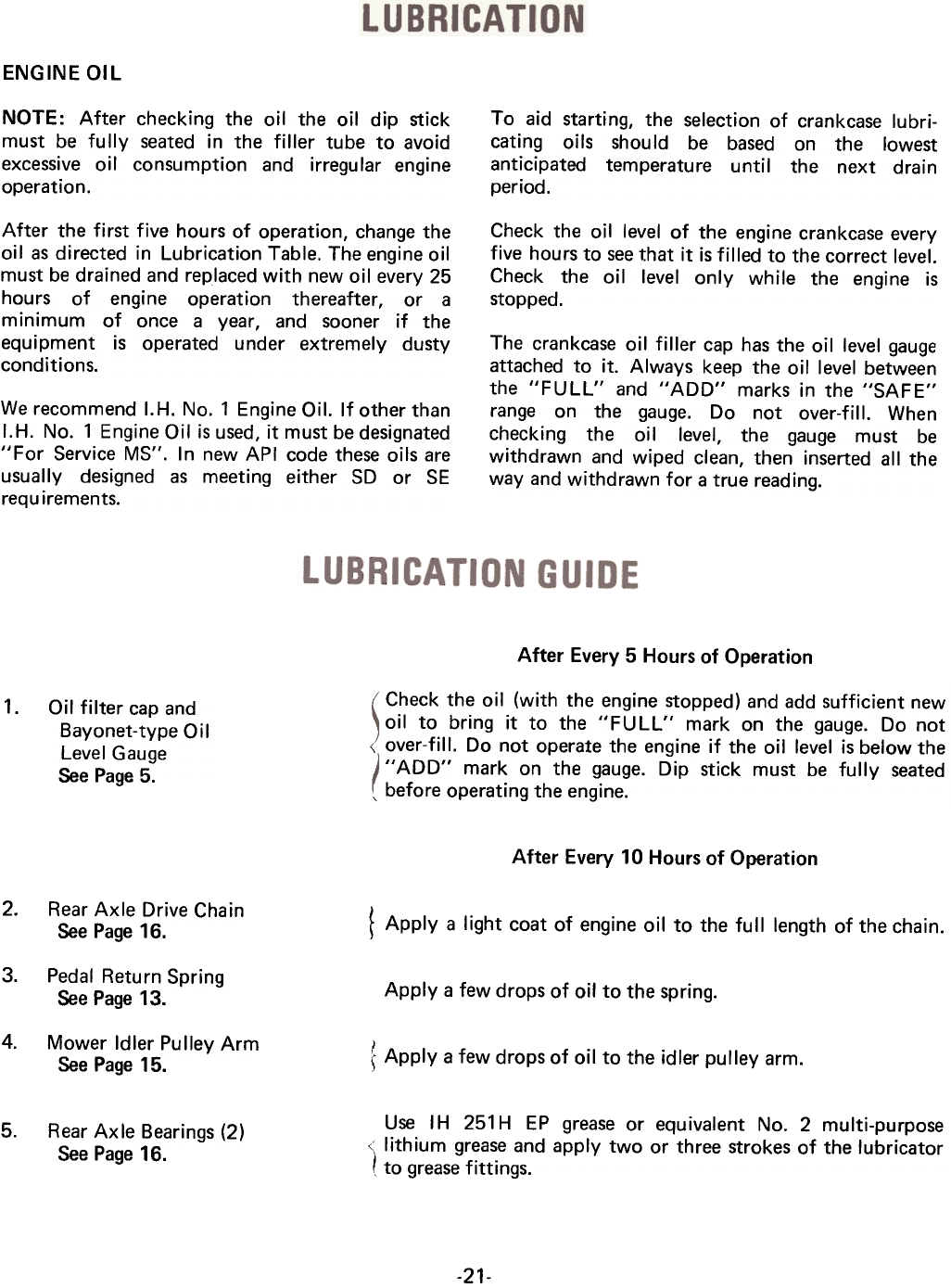

ENGINE Oil

NOTE: After checking the oil the oil dip stick

must be fully seated in the filler tube to avoid

excessive oil consumption and irregular engine

operation.

To aid starting, the selection of crankcase lubri-

cating oils should be based on the lowest

anticipated temperature until the next drainperiod.

After the first five hours of operation, change the

oil as directed in Lubrication Table. The engine oil

must be drained and replaced with new oil every 25

hours of engine operation thereafter, or a

minimum of once a year, and sooner if the

equipment is operated under extremely dusty

conditions.

Check the oil level of the engine crankcase every

five hours to see that it is filled to the correct level.

Check the oil level only while the engine is

stopped.

The crankcase oil filler cap has the oil level gauge

attached to it. Always keep the oil level between

the "FULL" and "ADD" marks in the "SAFE"

range on the gauge. Do not over-fill. When

checking the oil level, the gauge must be

withdrawn and wiped clean, then inserted all the

way and withdrawn for a true reading.

We

recommend I.H. No.1 Engine Oil. If other than

I.H. No.1 Engine Oil is used, it must be designated

"For Service MS". In new API code these oils are

usually designed as meeting either SO or SE

requ irements.

After Every 5 Hours of Operation

Check the oil (with the engine stopped) and add sufficient new

oil to bring it to the "FU LL" mark on the gauge. Do not

\ over-fil'. Do not operate the engine if the oil level is below the

"ADD" mark on the gauge. Dip stick must be fully seated

, before operating the engine.

1.

Oil filter cap and

Bayonet-type Oil

Level Gauge

See Page 5.

After Every 10 Hours of Operation

2.

Rear Axle Drive Chain

See Page 16.

f Apply a light coat of engine oil to the full length of the chain.

3.

Pedal Return Spring

See Page 13.

Apply a few drops of oil to the spring.

4.

Mower Idler Pulley Arm

See Page 15.

Apply a few drops of oil to the idler pulley arm.

Use IH 251 H EP grease or equivalent No.2 multi-purpose

lithium grease and apply two or three strokes of the lubricator

to grease fittings.

5.

Rear Axle Bearings (2)

See Page 16.

-21-