Maintenance & Adjustments

6

15

WARNING! Do not make any adjustments without

stopping the engine, disconnecting the spark plug

wire, grounding it against the engine and relieving

the hydro system pressure. Always wear safety

glasses during operation or while performing any

adjustments or repairs.

Engine

Refer to the Engine Operator’s Manual packed with your log

splitter for all engine maintenance.

Tire Pressure

The max recommended operating pressure is 30 psi. Do

not, under any circumstances, exceed the manufacturer’s

recommended psi. Maintain equal pressure on all tires.

WARNING! Excessive pressure when seating beads

may cause the tire/rim assembly to burst with force

sufficient to cause serious injury. Refer to the

sidewall of the tire for recommended pressure.

Hydraulic Fluid

Check the hydraulic fluid level in the log splitter reservoir

tank before each use. Maintain the fluid level within the range

specified on the dipstick at all times.

Change the hydraulic fluid in the reservoir every 100 hours of

operation. The inlet filter should also be changed with each

hydraulic fluid change. Follow the steps below:

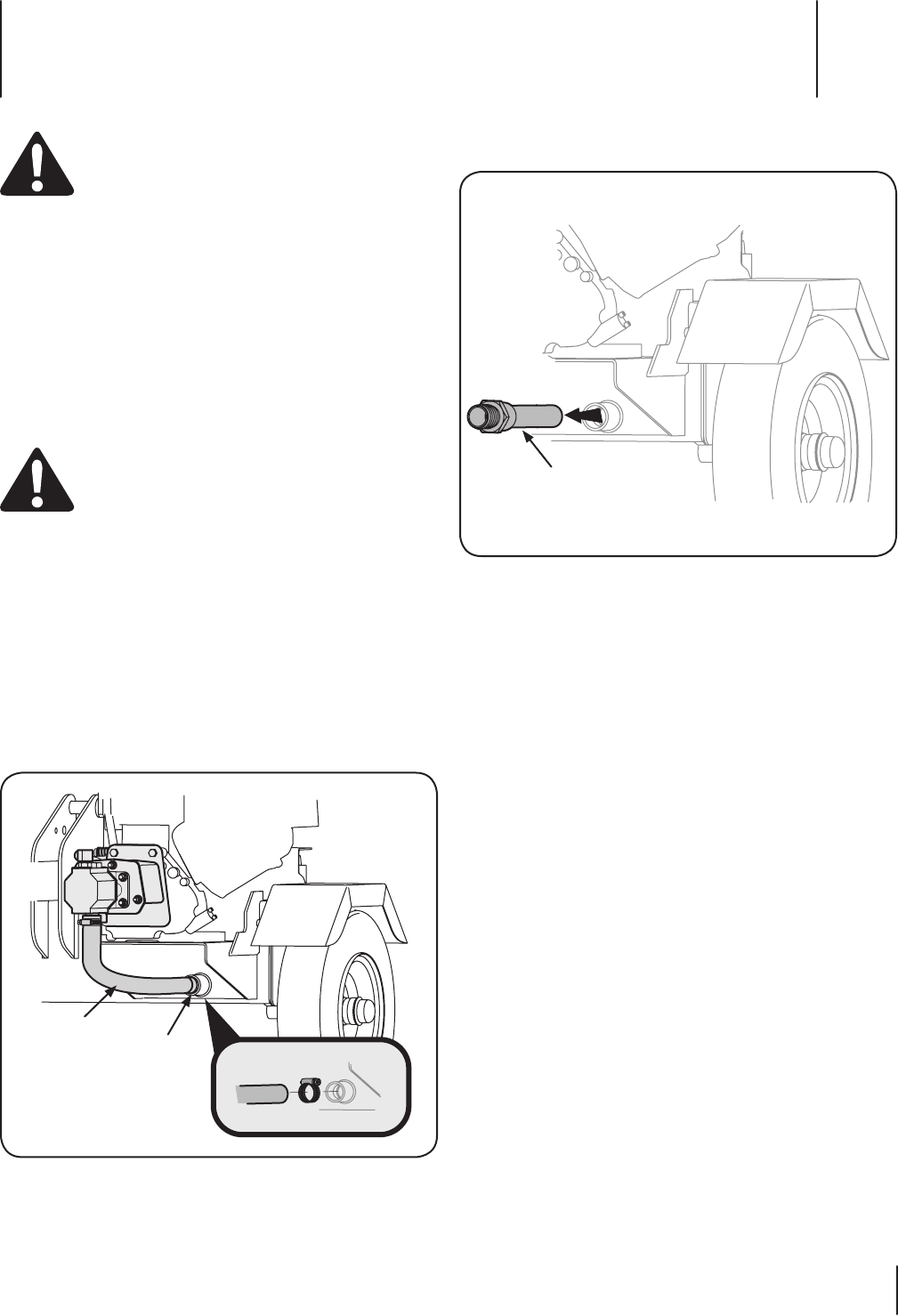

Place a suitable oil collection container under the tank.1.

Disconnect the suction hose from the bottom of the 2.

reservoir tank. See Fig. 6-1.

Carefully unthread the inlet filter and clean it with 3.

penetrating oil. See Fig. 6-2.

Allow the fluid to drain into a suitable container.4.

NOTE: The reservoir tank has a capacity of 3 gallons and

the entire hydraulic system has a capacity of approximately

4.7 gallons.

Reinstall the filter inlet screen and hose. Tighten the hose 5.

clamp.

Check the fluid level using the dipstick. Do not overfill. 6.

When checking the fluid, always make sure to tighten the

dipstick until the top of the threads are flush with the top of

the pipe.

NOTE: Approved fluids include Shell Tellus® S2 M 32 Hydraulic

Fluid, Dexron® III / Mercon® automatic transmission fluid, Pro-

Select™ AW-32 Hydraulic Oil or 10WAW-ISO viscosity grade 32

hydraulic oil. It is recommended that fluids not be mixed.

Replace the vented dipstick securely, tightening it until the 7.

top of the threads are flush with top of the pipe.

Disconnect the spark plug and prime the pump by pulling the 8.

recoil starter as far as it will go. Repeat approximately 10 times.

Reconnect the spark plug wire and start the engine 9.

following the instructions in the Engine Operator’s manual.

Use the control handle to engage the wedge to the farthest 10.

extended position. Then retract the wedge.

Suction

Hose

Inlet

Filter

Figure 6-1

Inlet Filter

Figure 6-2