20

level, paved area. If the leaking tire is on a

traction wheel, put blocks on each side of the

opposite traction wheel and jack up the tire

that leaks about an inch off the ground.

Loosen and remove the lug nuts and remove

the wheel. Mount a wheel and tire, replace the

lug nuts, and using a torque wrench, tighten

them to 60

±

10 ft-lbs.

If the leaking tire is on a front caster wheel,

block both traction wheels and raise the

caster wheel so that the tire is an inch off the

ground. Loosen and remove the locknut from

the axle assembly and pull the axle assembly

from the caster yoke. The wheel and two

spacer sleeves will drop free. Slip the axle

assembly through one side of the caster

yoke, through a spacer sleeve, a wheel, the

other spacer sleeve and finally through the

other side of the caster yoke. Then tighten

the locknut on the end of the axle assembly.

Lower the mower off the jack and continue

mowing. The wheel with the leaking tire

should be inflated to 20 psi and the wheel

placed in a large bucket of water. Carefully

inspect the tire, rim and valve for escaping air

bubbles which indicate a leak. Mark each

leak with a yellow marking crayon and then

deflate the tire to 8 psi and repeat the

inspection. If the leaks you find are pin hole

size to 1/16" diameter, the tire can be

repaired. If the leaks are larger than 1/16"

diameter, the tire can be repaired. If the tire

bead is damaged, the tire can be repaired or

the tire will have to be replaced.

3.

Creeping:

Creeping is the slight forward or

backward movement of the mower when the

throttle is on and the lapbars are in the

opened-out position. If your mower creeps do

the following.

a. Jack up rear of unit.

b. Place Lapbars in neutral opened-out posi-

tion.

c. Locate jam nuts on transaxle control arms.

(They are on the vertical linkage on the

front of the transaxles)

d. Loosen jam nuts on both ends of rod con-

nectors.

e. Start unit and push throttle all the way on.

f. If unit creeps forward, rotate vertical rod

links counter-clockwise. If unit creeps in

reverse, rotate clockwise.

Adjust the appropriate rod connector. The

left rod for the left side of the mower and

the right rod for the right side of mower.

Afterward, retighten jam nuts.

E. Brakes

While the mower is in motion, all braking is performed

dynamically through the hydraulic pumps and traction

motors, controlled by the two steering levers. When the

mower is parked with the engine shut off, the hydraulic

system locks the traction wheels.

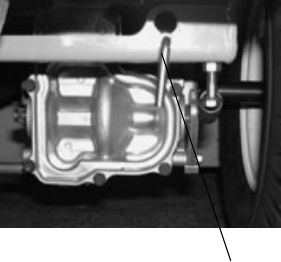

Note:

To move the mower forward or in

reverse by pushing, you must release the

dynamic braking. Locate the release levers at

the rear of the machine. Pull them toward the

rear and lower the wide area of the rod into the

keyhole slot. (See photo below)

.

When the mower is parked with the engine running

and the steering levers opened out in the neutral

position, the parking brakes should be applied. The

parking brakes are gear/pawl brakes mounted on

each traction wheel. They are both engaged by the

same operating lever.

1.

Adjustments:

The parking brake handle is a

lever in a “j” slot that should engage with mod-

erate force. The parking brakes provide a

positive means to hold a machine stationary

that is similar to “Park” on an automobile.

Note:

The parking brakes normally do not

need to be adjusted.

To adjust either brake individually, loosen the jam nuts

on the cable near the brake arm on the transaxle.

Adjust the nuts so that the brake/pawl comes closer to

the gear, but not in contact with the gear teeth.

2.

Repair:

The mower is equipped with external

gear/pawl brakes and will not normally require

maintenance. If they are not working properly,

please contact your service center.

F. Hydraulic System

1.

Hydrostatic Pumps and Motors:

The pumps

in the transaxles are the hardest-working

components in the hydraulic system. They are

in operation all the time the engine is running.

Hydro Release Valve