22

CARBURETOR ADJUSTMENTS

WARNING

When making adjustments to the carburetor

while the engine is running, disengage the PTO

clutch and engage the brake pedal lock. Keep

clear of all moving parts and be careful of all hot

surfaces.

WARNING

Carbon monoxide fumes can be fatal! Do not

make any adjustments to the carburetor in a

confined area such as a storage building. Move

the tractor outside into the air.

The carburetor is adjusted at the factory and under

normal operating conditions it will not require

readjusting. The high idle is set at the factory and

cannot be adjusted. If the engine does not operate

properly and the problem appears to be fuel system

related, check the following areas before adjusting the

carburetor: Refer to MAINTENANCE section.

• Check for fuel in fuel tank

• Check fuel cap vent for blockage

• Check fuel line for pinched or obstructed areas

• Check for fuel filter blockage

• Check for a clogged air filter

If, however, the engine is hard-starting or runs roughly

or stalls at low idle speed, it may be necessary to

adjust or service the carburetor. Minor carburetor

adjustment may also be needed to compensate for

differences in fuel, temperature or altitude.

The air filter element and element cover must be

assembled to the carburetor when running the engine.

Adjust the carburetor idle fuel mixture in the order

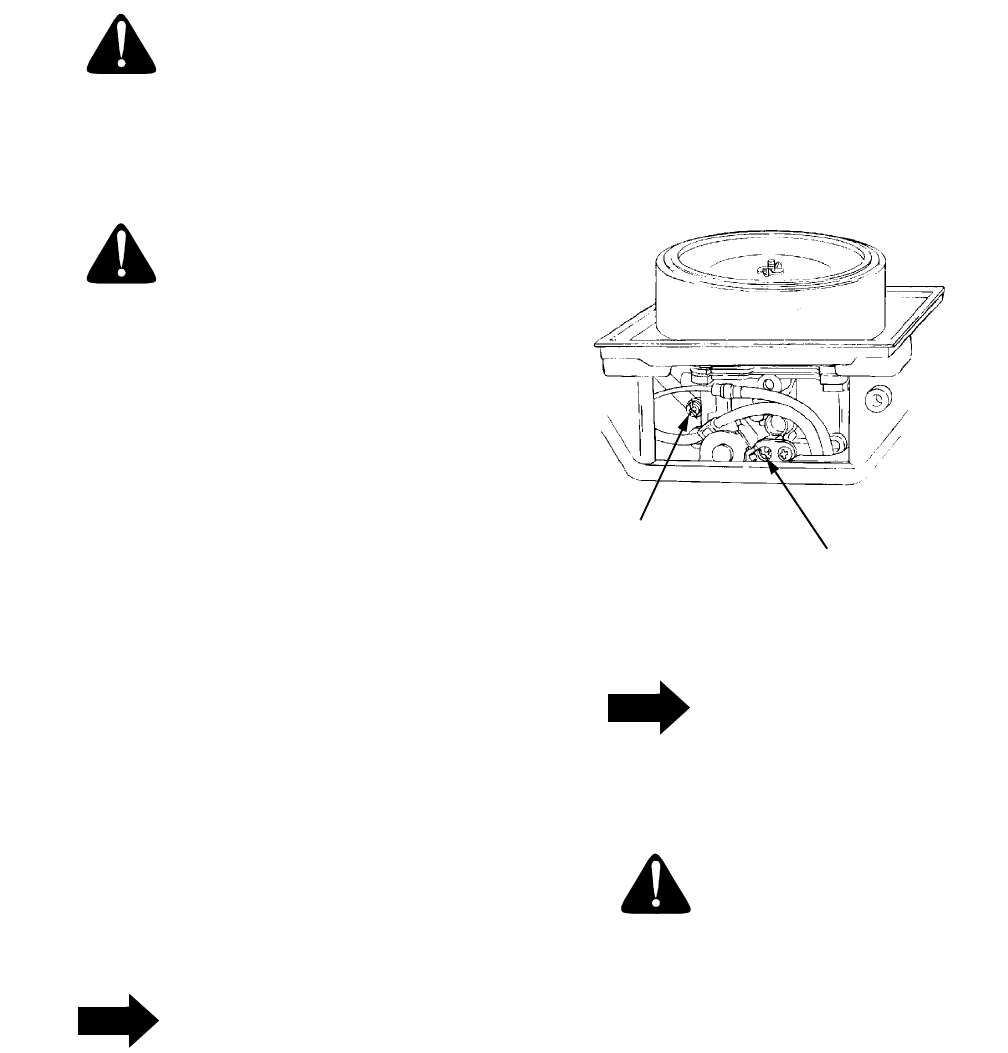

stated as follows (Refer to Figure 17):

NOTE

Carburetor adjustments should be made only

after the engine has warmed up.

1. Start the engine and run at half throttle for 5 to 10

minutes to warm up. The engine must be warm

before making the final settings. Check that the

throttle and choke plates can fully open.

2. Idle Speed Setting: Place the throttle control into

the “idle” or “slow” position. Set the low idle speed

to 1200 rpm (± 75 rpm) by turning the low idle

speed adjusting screw in or out. Check the speed

using a tachometer (See Figure 17).

Figure 17

NOTE

The recommended low idle speed for the en-

gine is 1200 rpm. To ensure best results when

setting the low idle fuel needle, the low idle

speed must not exceed 1200 rpm (± 75 rpm).

CAUTION

The tip of the low idle fuel adjusting needle is

tapered to critical dimensions. Damage to the

needle and the seat in the carburetor body will

result if the needle is forced.

3. Low Idle Fuel Needle Setting: Place the throttle

into the “idle” or “slow” position. Turn the low idle

fuel adjusting needle in slowly until the engine

speed decreases, and then back out approximately

3/4 turn to obtain the best low speed performance.

4. Recheck the idle speed using a tachometer.

Readjust the speed as necessary.

NOTE: AIR CLEANER COVER MUST

BE REMOVED TO ADJUST

CARBURETOR IDLE SPEED

IDLE SPEED

ADJUSTING SCREW

AND SPRING

IDLE FUEL ADJUSTING

NEEDLE AND SPRING