43

WARNING

When servicing the mower deck, be careful not

to cut yourself on the sharpened blades.

Clean the underside of the mower deck at the end of

the mowing season or when buildup of cut material on

the underside is noticed. Also remove the belt covers

and remove any accumulated grass clippings.

If using the mulching option, clean the underside of the

deck frequently. A buildup of grass clippings will

prevent proper mulching.

The cutting blades must be kept sharp at all times.

NOTE

Sharpen the cutting and mulching edges of the

blades evenly so that the blades remain

balanced and the same angle of sharpness is

maintained. If the cutting edge of a blade has

been sharpened to within 5/8 inch of the wind

wing radius (see Figure 58), it is recommended

that new blades be installed. New blades are

available at your authorized dealer.

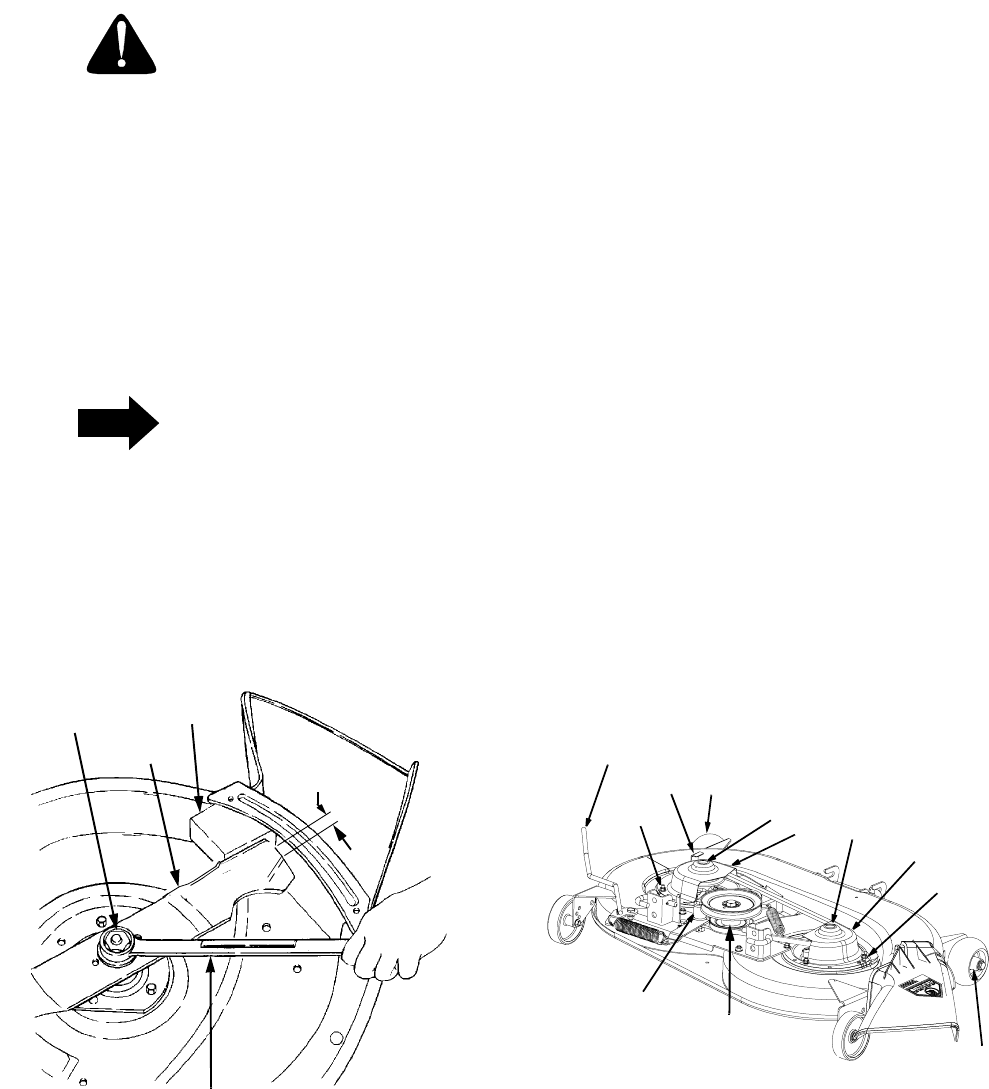

Figure 58

When removing the blades, use a 1-1/8 inch wrench to

hold the hex head of the spindle bolt when loosening

the hex nut securing the blade. A block of wood may

be placed between the deck housing and the cutting

edge of the blade to assist in removal of the hex nut

securing the blade (Refer to Figure 58).

After replacing the blades, apply grease the exposed

threads at the bottom of the spindle bolts to prevent

rust buildup.

When replacing the blades, be sure they are installed so

that the wind wings are pointing upward toward the top of

the deck housing. Tighten the nuts to 90 to 110 ft-lbs.

(122 to 149 N·m).

LUBRICATION

NOTE: We do not recommend the use of a pressure

washer or garden hose to clean your unit. They may

cause damage to electrical components; spindles;

pulleys; bearings; or the engine. The use of water will

result in shortened life and reduce serviceability.

After every 10 hours of operation and/or before putting

the deck into winter storage, lubricate the spindle as-

semblies and the spindle belt idler arm with 251H EP

grease or an equivalent No. 2 multipurpose lithium

grease. Excess grease will be expelled from the invert-

ed upper seals of the spindle assemblies. Listen for

the muffled crackling noise of grease being expelled

through the seal to indicate the spindle assembly is ful-

ly greased. Refer to Figure 59.

Every 50 hours, or twice yearly, lubricate the double

pulley with 251H EP grease or an equivalent No. 2

multipurpose lithium grease. Do not over lubricate.

Refer to Figure 59.

Figure 59

5/8" From

Radius

1-1/8 INCH WRENCH

WOOD

BLOCK

BLADE

HEX

NUT

1. Spindle Belt Cover

2. Flange Lock Nuts

3. Idler Arm Lever

4. Stop Bracket

6. Spindle Assembly

Grease Fittings

7. Idler Arm

Grease Fitting

5. Front Ball Wheels

1

2

3

4

5

1

2

5

6

7

6

8. Double Pulley

8