27

6. Remove the oil fill plug/dipstick from the oil fill port

and SLOWLY pour oil into the oil fill port. Fill the

transmission case until the oil level reaches the

“FULL” mark on the dipstick (Refer to Figure 21).

Figure 23

7. Reinstall the oil fill plug/dipstick securely into the

oil fill port.

8. Start the engine and allow it to run for a few

minutes. Shut the engine off, then check for leaks

and re-check the oil level in the transmission case.

CAUTION

The oil fill plug/dipstick MUST BE INSTALLED

SECURELY INTO THE FILL PORT AT ALL

TIMES WHEN THE ENGINE IS OPERATING.

AIR CLEANER

Check the air cleaner daily or before starting the

engine. Check for loose or damaged components and

check the condition of the filter element. Remove any

buildup of dirt and debris in the air cleaner housing.

NOTE

Operating the engine with loose or damaged air

cleaner components will allow unfiltered air into

the carburetor; causing extensive wear and

eventual failure of the engine.

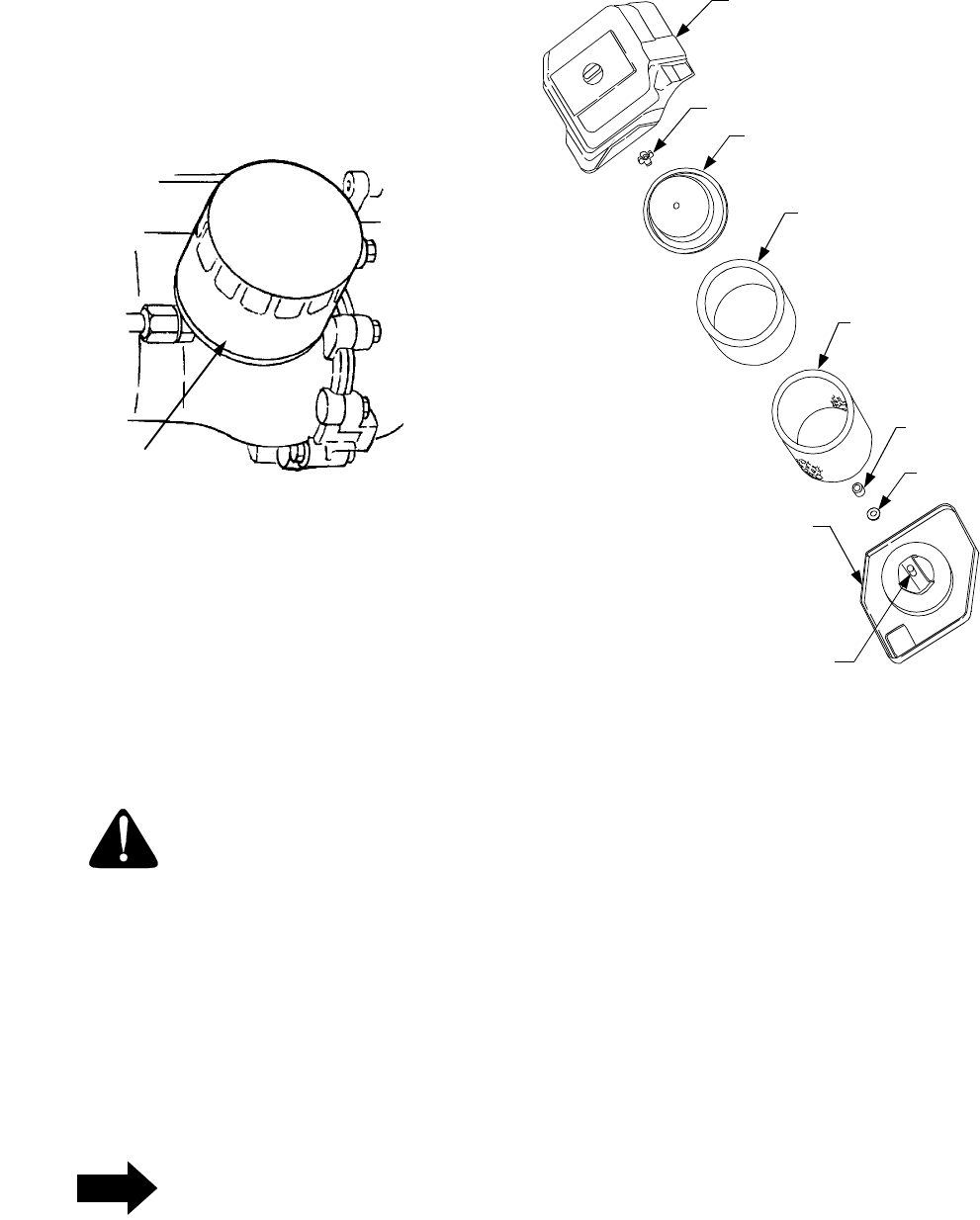

Figure 24. Air Cleaner Assembly.

Servicing the Precleaner

Wash and re-oil the foam precleaner at one month

intervals or after every 10 hours of operation (more

often under extremely dusty or dirty conditions),

whichever occurs first.

1. Unfasten the air cleaner cover retaining knob and

remove the air cleaner cover (See Figure 24).

2. Remove the foam precleaner by sliding it up off the

paper element (See Figure 24).

3. Wash the precleaner in warm water with

detergent. Rinse the precleaner thoroughly until all

traces of the detergent are eliminated. Squeeze

out (do not wring) excess water in a dry cloth.

Allow the precleaner to air dry.

4. Saturate the foam precleaner with new engine oil.

Squeeze out all excess oil.

5. Reinstall the foam precleaner over the paper

element.

6. Reinstall the air cleaner cover and secure with the

retaining knob.

TRANSMISSION

OIL FILTER

1

2

3

4

5

6

8

7

9

1.

2.

3.

4.

5.

6.

7.

8.

9.

COVER W/KNOB

WING NUT

COVER PLATE

FOAM PRECLEANER

PAPER ELEMENT

GROMMET SEAL

RETAINING RING

BASE BACKPLATE

CARRIAGE BOLT