SERVICE AND ADJUSTMENTS

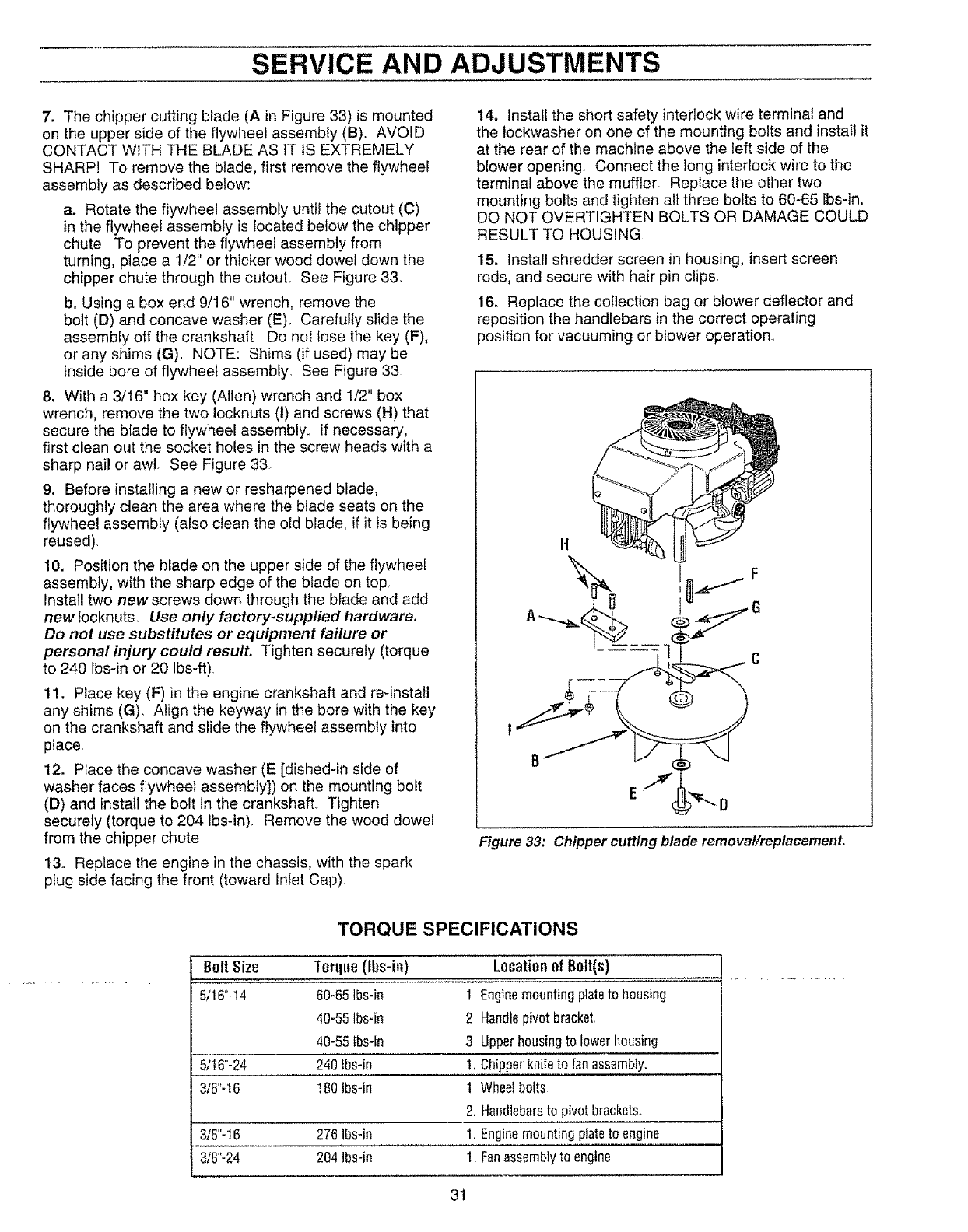

7, The chipper cutting blade (A in Figure 33) is mounted

on the upper side of the flywheel assembly (B). AVOID

CONTACT WITH THE BLADE AS IT tS EXTREMELY

SHARP! To remove the blade, first remove the flywheel

assembly as described below:

a. Rotate the flywheel assembly until the cutout (C)

in the flywheel assembly is located below the chipper

chute, To prevent the flywheel assembly from

turning, place a 1/2" or thicker wood dowel down the

chipper chute through the cutout. See Figure 33.

b, Using a box end 9/16" wrench, remove the

bolt (D) and concave washer (E) Carefully slide the

assembly off the crankshaft Do not lose the key (F),

or any shims (G), NOTE: Shims (if used) may be

inside bore of flywheel assembly, See Figure 33

8. With a 3/16" hex key (Allen) wrench and 1/2" box

wrench, remove the two Iocknuts (I) and screws (H) that

secure the blade to flywheel assembly., If necessary,

first clean out the socket holes in the screw heads with a

sharp nail or awl, See Figure 33

9. Before installing a new or resharpened blade,

thoroughly clean the area where the blade seats on the

flywheel assembly (also clean the old blade, if it is being

reused).

10. Position the blade on the upper side of the flywheel

assembly, with the sharp edge of the blade on top,

Install two new screws down through the blade and add

new focknuts_ Use only factory-supplied hardware.

Do not use substitutes or equipment failure or

personal injury could result. Tighten securely (torque

to 240 lbs-in or 20 Ibs-ft)

11. Place key (F) in the engine crankshaft and re-install

any shims (G). Align the keyway in the bore with the key

on the crankshaft and slide the flywheel assembly into

place

12. Place the concave washer (E [dished-in side of

washer faces flywheel assembly]) on the mounting bolt

(D) and install the bolt in the crankshaft. Tighten

securely (torque to 204 Ibs-in) Remove the wood dowel

from the chipper chute

13. Replace the engine in the chassis, with the spark

plug side facing the front (toward Inlet Cap)

14. Install the short safety interlock wire terminal and

the lockwasher on one of the mounting bolts and install it

at the rear of the machine above the left side of the

blower opening. Connect the long interlock wire to the

terminal above the muffler. Replace the other two

mounting bolts and tighten all three bolts to 60-65 Ibs-in.

DO NOT OVERTIGHTEN BOLTS OR DAMAGE COULD

RESULT TO HOUSING

15. install shredder screen in housing, insert screen

rods, and secure with hair pin clips.

16. Replace the collection bag or blower deflector and

reposition the handlebars in the correct operating

position for vacuuming or blower operation°

Figure 33t Chipper cutting blade removal/replacement,

TORQUE SPECIFICATIONS

BoltSize Torque(Ibs-in) Locationof Bolt(s)

5/16"-t4 60-65]Bs-in 1 Enginemountingplatetohousing

40-55Ibs-in 2 Handlepivotbracket

40-55tbs-in 3 Upperhousingto lowerhousing

5/16"-24 240tbs-in 1. Chipperknifeto fanassembly.

3/8"-t6 180lbs-in 1 Wheelballs

2. Handlebarstopivotbrackets.

3/8"-16 276lbs-in 1. Enginemountingplateto engine

3/8"-24 204lbs-in 1 Fanassemblyto engine

31