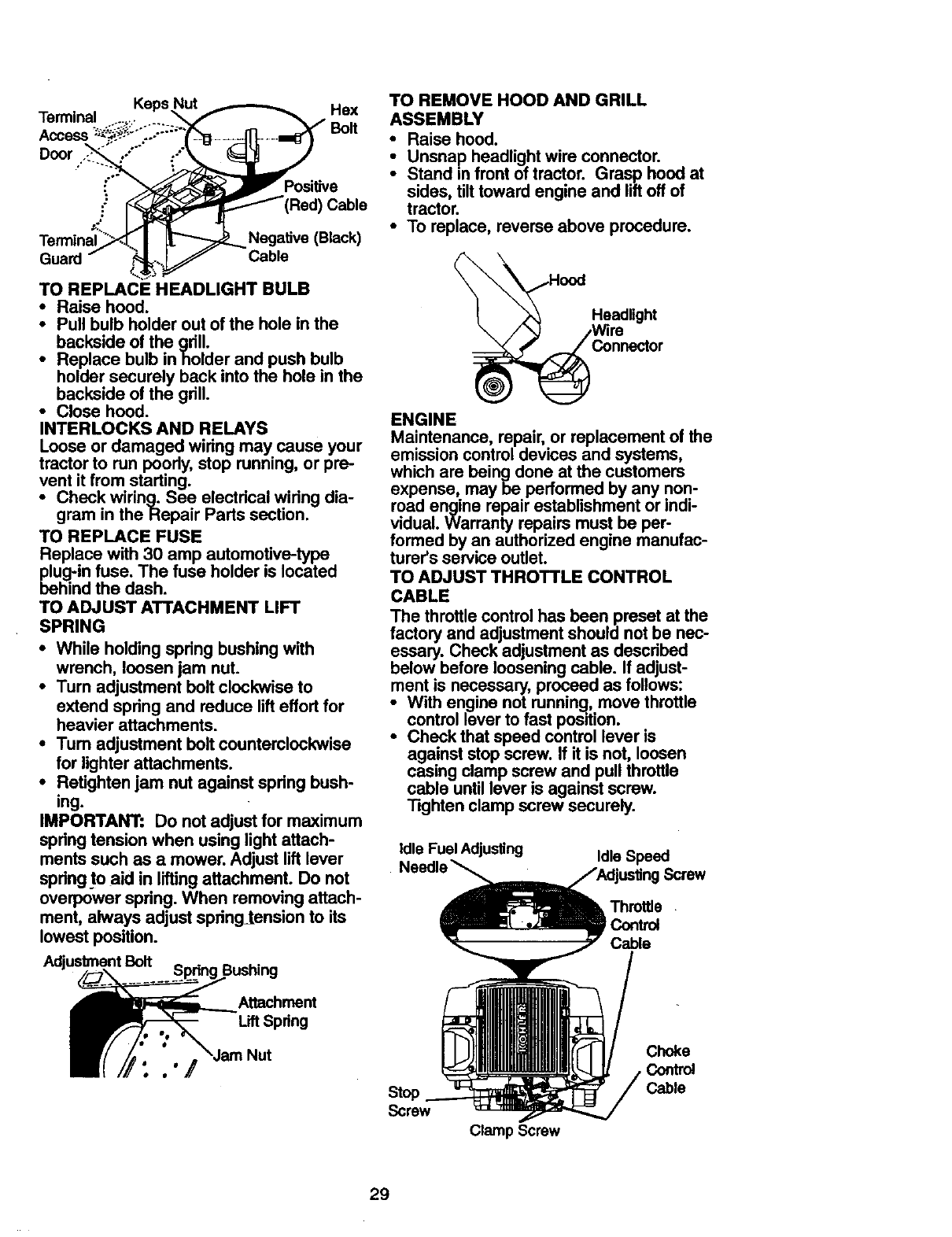

KepsNut_ u..., TO REMOVE HOOD AND GRILL

Terminal ..... _ _- _ .. ' '°^ ASSEMBLY

A=e ....

Bolt

• Raise hood.

Door..___."-"" - • Unsnap headlightwire connector.

_Positive Stand in front of tractor. Grasp hood at:.--"

sides, tilttoward engine and liftoff of

.- _ (Red)Cable tractor.

Terrain=_'_-/-_...= _""_ Negative(Black) • To replace, reverse above procedure.

Guard/ _'f_L-.J// Cable

TO REPLACE HEADLIGHT BULB

• Raise hood.

• Pull bulb holder out of the hole in the

backside of the gdll.

• Replace bulb inholder and push bulb

holder securely back into the hole in the

backside of the grill.

• Close hood.

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause your

tractor to run poorly, stop running, or pre-

vent it from starting.

• Check wiring. See electrical wiring dia-

gram in the Repair Parts section.

TO REPLACE FUSE

Replace with 30 amp automotive-type

plug-in fuse. The fuse holder is located

behind the dash.

TO ADJUST ATTACHMENT LIFT

SPRING

• While holding spring bushing with

wrench, loosen jam nut.

• Turn adjustment bolt clockwise to

extend spring and reduce lift effort for

heavier attachments.

•Tum adjustment boltcounterclockwise

for lighter attachments.

• Retighten jam nut against spdng bush-

ing.

IMPORTANT: Do not adjust for maximum

spdng tension when using lightattach-

ments such as a mower. Adjust lift lever

springto aid in liftingattachment. Do not

overpower spring. When removing attach-

ment, always adjust spring]ension to its

lowest position.

AdjU__Bushing

_Attachment

_Lift Spdng

!(//" - / JamNut

Headlight

ENGINE

Maintenance, repair, or replacement of the

emission control devices and systems,

which are being done at the customers

expense, may be performed by any non-

road engine repair establishment or indi-

vidual. Warranty repairs must be per-

formed by an authorized engine manufac-

turer's service outlet.

TO ADJUST THROTTLE CONTROL

CABLE

The throttlecontrol has been preset at the

factory and adjustment should not be nec-

essary. Check adjustment as described

below before looseningcable. If adjust-

ment is necessary, proceed as follows:

With engine not running, move throttle

control lever to fast position.

Check that speed control lever is

against stop screw. If it is not, loosen

casing clamp screw and pullthrottle

cable untillever is against screw.

Tighten clamp screw securely.

Idle FuelAdjusting

Idle Speed

IScrew

Throttle.

Cable

Stop

Screw

Clamp Screw

Choke

,Control

Cable

29