CAUTION: Never run the engine without

the air cleaner element installed. A

defective air cleaner can result in loss of

engine power and can cause excessive

wear or damage to the engine components

if dirt or dust is permitted to enter the

engine through the carburetor. A damaged

air cleaner, or one that is clogged with dust

or dirt should be replaced immediately.

SPARK PLUG

Clean the spark plug and reset the gap

periodicany. Clean the area around the

spark plug base before removal, to prevent

dirt from entering the engine. Replace the

spark plug ifthe electrodes are pitted or

burned or ifthe porcelain is cracked. Clean

the spark plug by carefully scraping the

electrodes (do not sand blast or use a wire

brush). Be sure the spark plug is clean and

free of foreign material. Check the elec-

trodes gap with a wire feeler gauge and

reset to .030 inches if necessary. If a new

spark plug is needed, refer to the PROD-

UCT SPECIFICATIONS on page 11 for the

proper replacement spark plug.

Before reinstalling the spark plug, coat the

threads lightly with graphite or light oil to

insure easy removal. Tighten the spark plug

firmly into the engine. If a torque wrench is

available, torque the spark plug to 15 foot-

pounds.

Z_ CAUTION: Always stop the engine

and disconnect the spark plug wire before

making any repairs to the Edger.

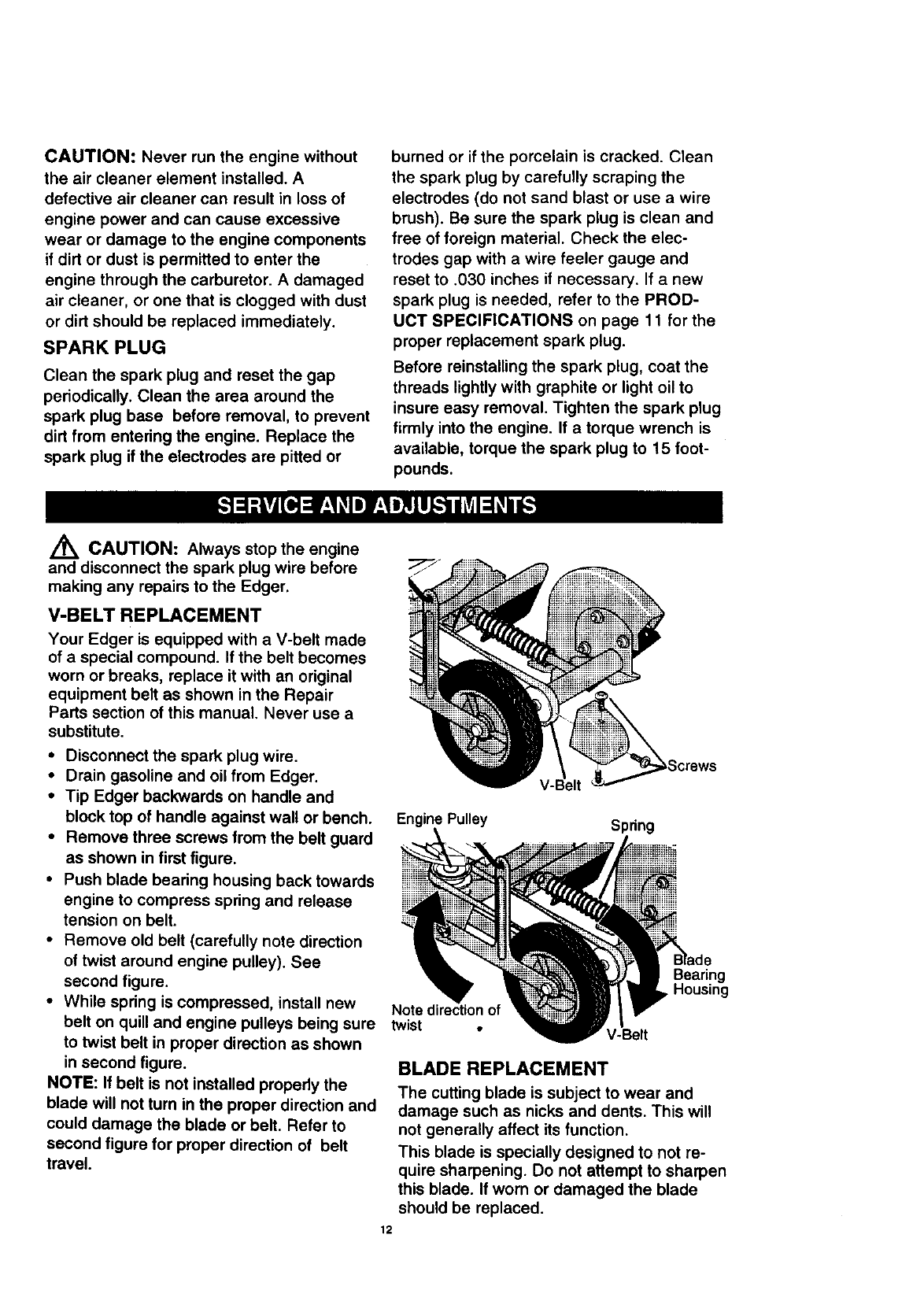

V-BELT REPLACEMENT

Your Edger is equipped with a V-belt made

of a special compound. If the belt becomes

worn or breaks, replace it with an original

equipment belt as shown in the Repair

Parts section of this manual. Never use a

substitute.

• Disconnect the spark plug wire.

• Drain gasoline and oil from Edger.

• Tip Edger backwards on handle and

block top of handle against wall or bench.

• Remove three screws from the belt guard

as shown in first figure.

• Push blade bearing housing back towards

engine to compress spring and release

tension on belt.

• Remove old belt (carefully note direction

of twist around engine pulley). See

second figure.

• While spring is compressed, install new

belt on quill and engine pulleys being sure

to twist belt in proper direction as shown

in second figure.

NOTE: If belt is not installed propedy the

blade will not turn in the proper direction and

could damage the blade or belt. Refer to

second figure for proper direction of belt

travel.

e Pulley Spring

twist

V-Belt

BLADEREPLACEMENT

The cutting blade is subject to wear and

damage such as nicks and dents. This will

not generally affect its function.

This blade is specially designed to not re-

quire sharpening. Do not attempt to sharpen

this blade. If wom or damaged the blade

should be replaced.

12