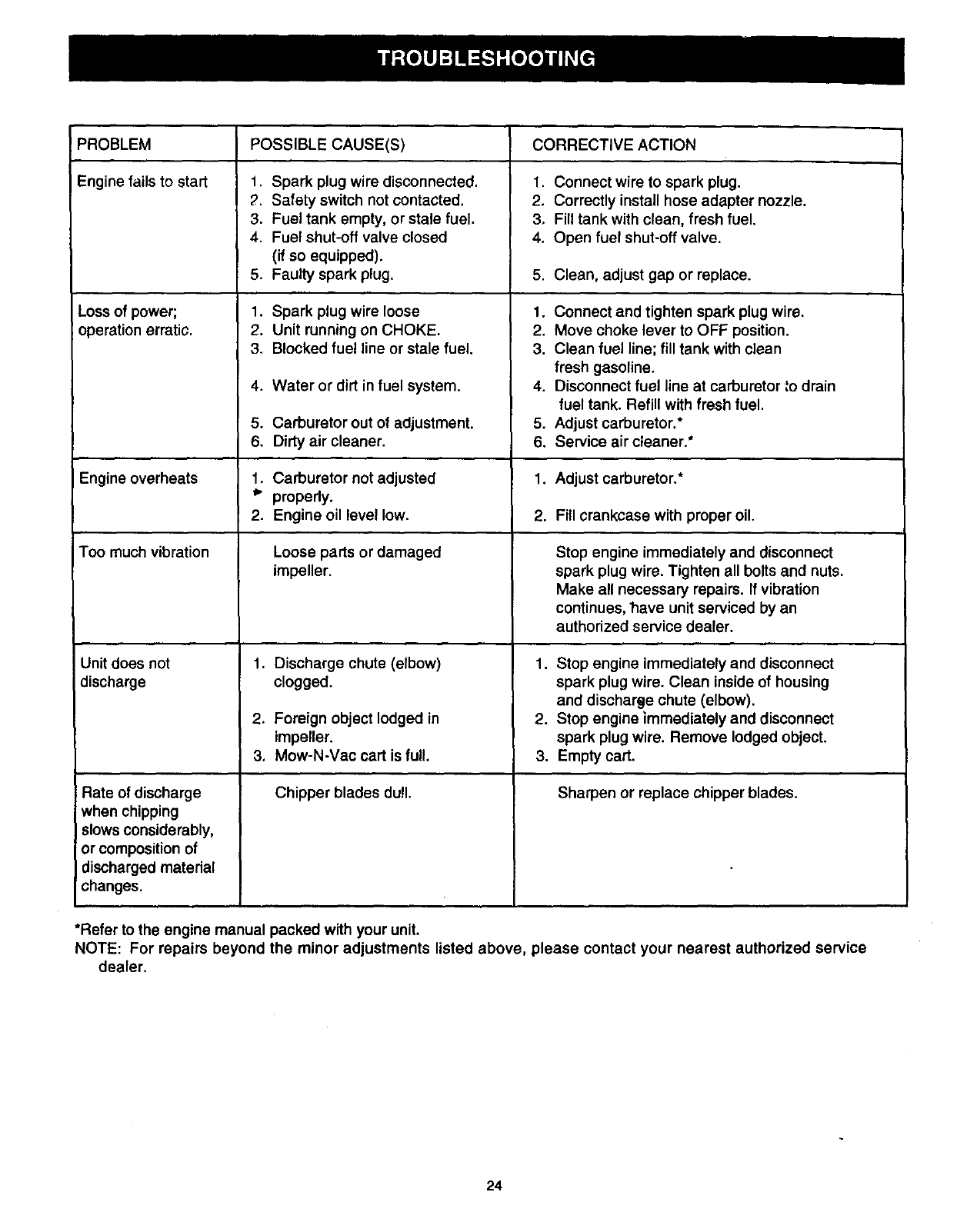

PROBLEM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Engine fails to start

Loss of power;

operation erratic.

Engine overheats

Too much vibration

Unit does not

discharge

Rate of discharge

when chipping

slows considerably,

or composition of

discharged material

changes.

1. Spark plug wire disconnected.

2. Safety switch not contacted.

3. Fuel tank empty, or stale fuel.

4. Fuel shut-off valve closed

(if so equipped).

5. Faulty spark plug.

1. Spark plug wire loose

2. Unit running on CHOKE.

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Carburetor out of adjustment.

6. Dirty air cleaner.

1. Carburetor not adjusted

pmpedy.

2. Engine oil level low.

Loose parts or damaged

impeller.

1. Discharge chute (elbow)

clogged.

2. Foreign object lodged in

impeller.

3, Mow-N-Vac cart isfull.

Chipper blades dull.

1, Connect wire to spark plug.

2. Correctly install hose adapter nozzle.

3, Fill tank with clean, fresh fuel.

4, Open fuel shut-off valve.

5. Clean, adjust gap or replace.

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean

fresh gasoline.

4. Disconnect fuel line at carburetor ,'o drain

fuel tank. Refill with fresh fuel.

5. Adjust carburetor.*

6. Service air cleaner.*

1. Adjust carburetor.*

2. Fill crankcase with proper oil.

Stop engine immediately and disconnect

spark plug wire. Tighten all bolts and nuts.

Make all necessary repairs. If vibration

continues, have unitserviced by an

authorized service dealer.

1. Stop engine immediately and disconnect

spark plug wire. Clean inside of housing

and discharge chute (elbow).

2. Stop engine immediately and disconnect

spark plug wire. Remove lodged object.

3. Empty cart.

Sharpen or replace chipper blades.

*Refer to the engine manual packed with your unit.

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest authorized service

dealer.

24