Disconnectsparkplug wire and move itaway

from spark plug.

Lowerthehopperassembly.Block upthe

housing.See figure19.

Weld Bolt

Allen

Screw

Pipe

causedamagetotheunit.The bladecan betasted

for balance bybalancingitona roundshaft

screwddverornail.Removemetalfrom theheavy

sideuntilitisbalancedevenly.See figure20.

When reassemblingtheblade, tightencenter

bolttobetween 550 and 650 inch-poundsand

thetwo outerboltsto between250and 350 inch-

pounds,or lackingtorquewrench,tighten

securely.

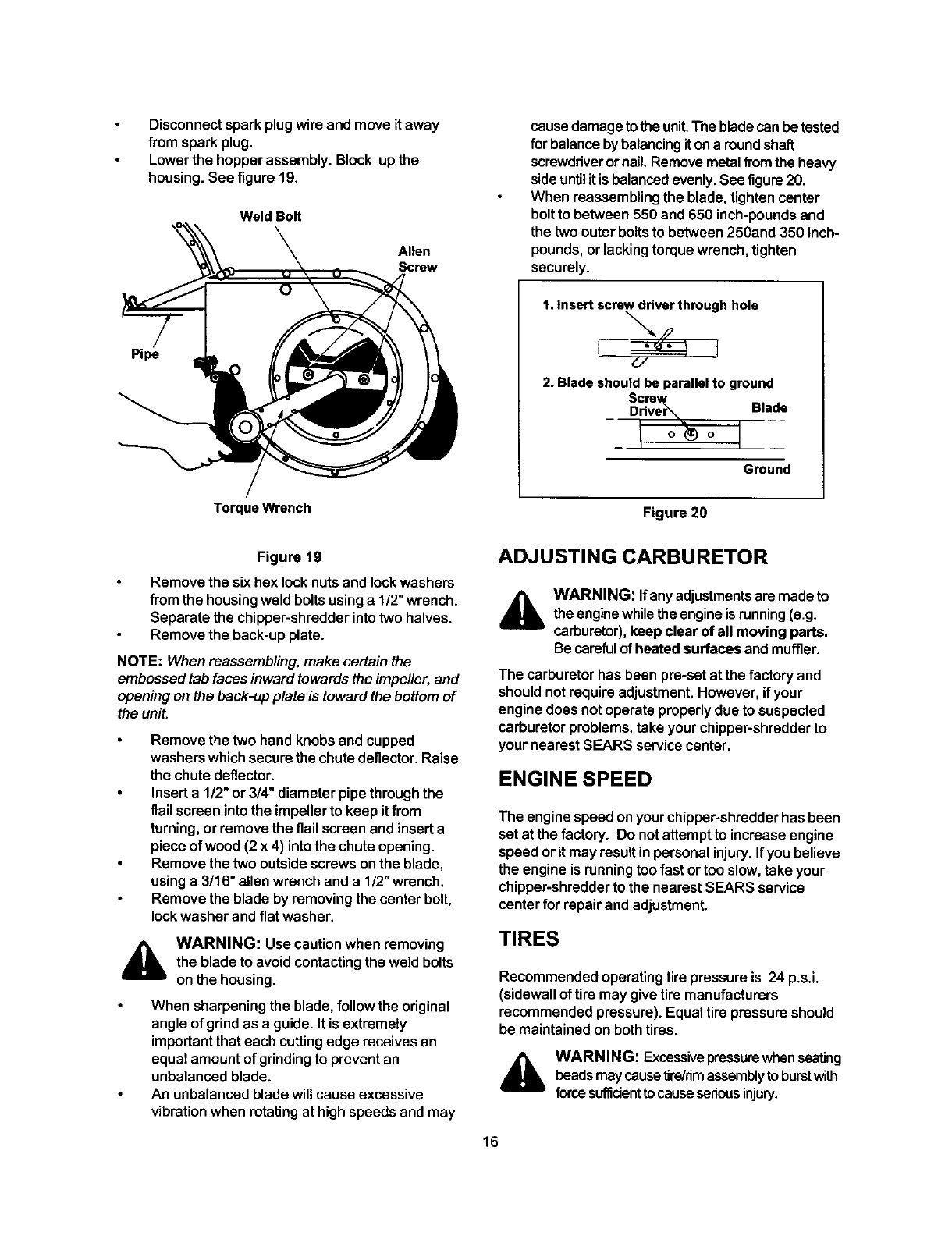

1.insertscrewdriverthroughhole

d/

2. Bladeshouldbe parallelto ground

Screv_

Driver\ Blade

i I --

Ground

Torque Wrench

Figure 20

Figure 19

Remove the sixhexlocknutsand lockwashers

from thehousingweld boltsusinga 1/2"wrench.

Separate the chipper-shredderintotwo halves.

Remove the back-upplate.

NOTE: When reassembling, make certain the

embossed tab faces inward towards the impeller,and

opening on the back-up plate is toward the bottom of

the unit.

Remove the two hand knobs and cupped

washerswhichsecurethechutedeflector. Raise

thechute deflector.

Inserta 1/2"or 3/4" diameterpipethroughthe

flailscreenintothe impellertokeep itfrom

turning,or removetheflailscreenand inserta

piece ofwood(2 x4) intothe chuteopening.

Removethe twooutsidescrewson theblade,

usinga 3/16" allenwrenchand a 1/2"wrench.

Remove theblade byremoving the center bolt,

lockwasher and fiatwasher.

,_ WARNING: Usecautionwhen removing

theblade to avoidcontacting theweld bolts

on thehousing.

When sharpening the blade, follow theoriginal

angleofgrind as a guide. Itisextremely

important that each cutting edge receives an

equat amount of grinding to prevent an

unbalanced blade.

An unbalanced blade will cause excessive

vibration when rotating at high speeds and may

ADJUSTING CARBURETOR

A

WARNING: Ifanyadjustmentsaremade to

the engine whiletheengineisrunning(e.g.

carburetor),keep clear ofall moving parts.

Becareful ofheated surfaces andmuffler.

The carburetor has been pre-set at the factory and

shouldnot requireadjustment.However, ifyour

enginedoes notoperate properlydue to suspected

carburetor problems,take yourchipper-shredderto

yournearestSEARS servicecenter.

ENGINE SPEED

The engine speed onyour chipper-shredderhas been

set at the factory. Do not attempt to increase engine

speed or it may result in personal injury. If you believe

the engine is running too fast or too slow, take your

chipper-shredder to the nearest SEARS service

center for repair and adjustment.

TIRES

Recommendedoperating tire pressure is 24 p.s.i.

(sidewalloftire maygive tire manufacturers

recommendedpressure).Equaltire pressureshould

be maintained on bothtires.

WARN ING: Excessivepressurewhenseating

beadsmay causetire/rimassemblytoburstwith

forcesufficienttocauseseriousinjury.

16