4, Removethechipperchutesupportbracefromthe frameby

removingthe hexbolts.

5. Rotateimpellerassemblybyhanduntil youlocateone of two

chipperbladesin thechipperchuteopening.

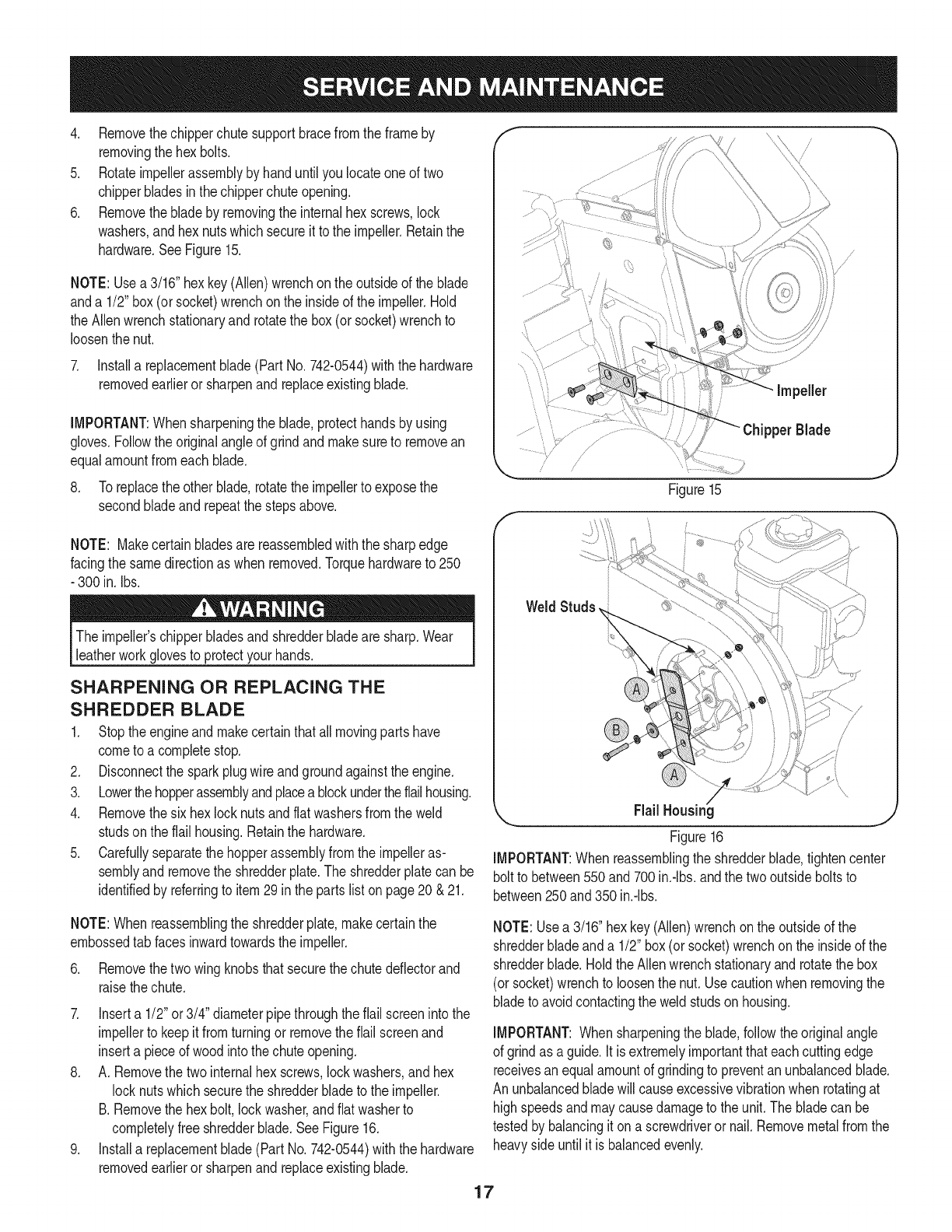

6, Removethebladeby removingthe internalhex screws,lock

washers,andhex nutswhichsecureit to the impeller.Retainthe

hardware,SeeFigure15,

NOTE:Usea3/16" hexkey(Allen)wrenchon theoutsideof the blade

anda 1/2"box(or socket)wrenchonthe insideoftheimpeller.Hold

the Allenwrenchstationaryand rotatethebox(or socket)wrenchto

loosenthenut.

7. Installa replacementblade(Part No.742-0544)withthe hardware

removedearlieror sharpenand replaceexistingblade.

IMPORTANT:Whensharpeningtheblade,protecthandsby using

gloves.Followthe originalangleofgrindandmakesuretoremovean

equalamountfromeachblade.

8. Toreplacetheother blade,rotatethe impellertoexposethe

secondbladeand repeatthe stepsabove.

NOTE: Makecertainbladesare reassembledwiththe sharpedge

facingthe samedirectionaswhenremoved.Torquehardwareto 250

- 300in. Ibs.

The impeller'schipperbladesand shredderbladearesharp.Wear

leatherworkglovesto protectyourhands.

SHARPENING OR REPLACING THE

SHREDDER BLADE

1. Stopthe engineandmakecertainthatallmovingpartshave

cometo a completestop.

2. Disconnectthe sparkplugwire andgroundagainsttheengine.

3. Lowerthehopperassemblyandplacea blockundertheflailhousing.

4. Removethesix hexlocknutsandflatwashersfromthe weld

studsonthe flail housing.Retainthe hardware.

5. Carefullyseparatethe hopperassemblyfromthe impelleras-

semblyand removethe shredderplate.Theshredderplatecanbe

identifiedby referringto item29in thepartsliston page20 &21.

Impeller

Blade

J

Figure15

Weld Studs,

/

Flail Housing

Figure16

IMPORTANT:Whenreassemblingthe shredderblade,tightencenter

bolttobetween550and700in.-Ibs,andthe twooutsideboltsto

between250and350in.-Ibs.

NOTE:Whenreassemblingthe shredderplate,makecertainthe

embossedtab facesinwardtowardstheimpeller.

6. Removethetwo wingknobsthatsecurethe chutedeflectorand

raisethechute.

7. Inserta 1/2"or3/4" diameterpipethroughthe flail screenintothe

impellerto keepit fromturningor removethe flailscreenand

inserta pieceof woodintothechuteopening.

8. A.Removethe twointernalhex screws,lockwashers,andhex

locknutswhichsecurethe shredderbladeto the impeller.

B. Removethehexbolt,lockwasher,andflat washerto

completelyfreeshredderblade.SeeFigure16.

9. Installa replacementblade(Part No.742-0544)withthe hardware

removedearlieror sharpenandreplaceexistingblade.

NOTE:Usea 3/16"hexkey(Allen)wrenchonthe outsideofthe

shredderbladeanda 1/2"box(or socket)wrenchon theinsideof the

shredderblade.HoldtheAllenwrenchstationaryand rotatethe box

(orsocket)wrenchto loosenthenut. Usecautionwhen removingthe

bladeto avoidcontactingthe weldstudson housing.

IMPORTANT:Whensharpeningthe blade,followtheoriginalangle

of grindas a guide.It isextremelyimportantthateachcuttingedge

receivesan equalamountofgrindingto preventan unbalancedblade.

An unbalancedbladewillcauseexcessivevibrationwhen rotatingat

highspeedsandmaycausedamageto theunit.The bladecanbe

testedbybalancingit on ascrewdriverornail. Removemetalfromthe

heavysideuntilitis balancedevenly.

17