MAINTENANCE SCHEDULE

Beforeperforminganytypeof maintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationor whileperforminganyadjustmentsor repairs.

Followthe maintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.Usethe ServiceLogcolumnto keeptrackof

completedmaintenancetasks.Tolocatethe nearest SearsService

Centeror to scheduleservice,simplycontactSears at

1-800-4-MY-HOME®.

EachUse

1st5 - 8 hours

25 hours

Annuallyor 50hours

Annuallyor 100hours

BeforeStorage 1. Fuelsystem

Underheavyloador inhightemperatures

.

2.

3.

1.

1.

2.

3.

1.

2.

1.

Engineoillevel

Looseormissinghardware

Unitandengine.

Engineoil

Engineoill-

Aircleaner

Controllinkagesand pivots

Engineoil

Muffler

Sparkplug

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Change

2. Replace

3. Lubewithlightoil

1. Change

2. Inspect

1. Clean,checkand resetgap,or

replacesparkplug.

1. Runengineuntilit stopsfromlackof

fuel oradda gasolineadditivetothe

gas in thetank.

Alwaysstopengineanddisconnectsparkplugwire beforeperforming

I anymaintenanceoradjustments.Alwayswearsafetyglassesduring

[operationor whileperforminganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

• Alwaysobserveallsafetyrulesfoundonproductlabelsandin

thisoperator'smanualwhenperforminganymaintenance.Safety

rulescanbefoundonthe productlabelsandin thisOperator's

Manualbeginningon page3.

• Thewarrantyon thischippershredderdoes notcoveritemsthat

havebeensubjectedto operatorabuseor negligence.Toreceive

fullvaluefromwarranty,operatormustmaintainthe equipmentas

instructedhere.

• Someadjustmentswillhaveto be madeperiodicallyto maintain

yourunitproperly.

• Periodicallycheckall fastenersand makesurethesearetight.

ENGINE MAINTENANCE

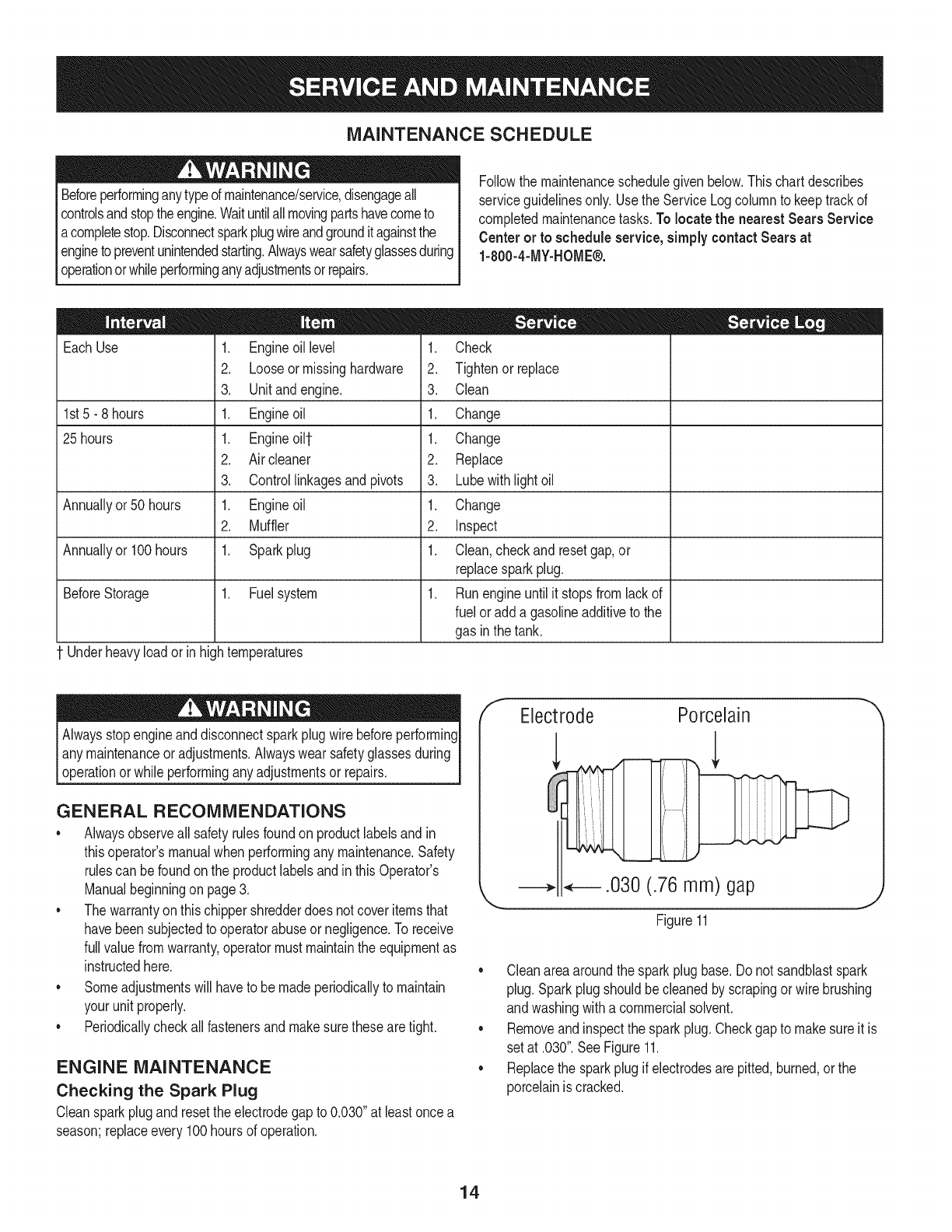

Checking the Spark Plug

Cleansparkplugandresettheelectrodegapto 0.030"at leastoncea

season;replaceevery100hoursof operation.

f

Electrode

Porcelain

,L

.030 (.76 mm) gap

Figure 11

• Cleanareaaroundthe sparkplugbase.Donot sandblastspark

plug. Sparkplugshouldbecleanedbyscrapingor wirebrushing

andwashingwitha commercialsolvent.

• Removeandinspectthe sparkplug.Checkgapto makesureitis

setat .030".SeeFigure11.

• Replacethe sparkplugif electrodesare pitted,burned,or the

porcelainis cracked.

14