Page 18 Page 11

Deck Levels - Front to BackTyres - Check List

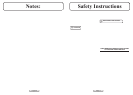

The Cutter Deck should be set so that it is parallel to the

surface it is cutting with a maximum variation from side to

side, or front to back of 3mm. Check this by placing the

Tractor on a hard level surface and measuring the clearance

heights front to back and side to side with a steel ruler or tape

with the Cutter set one adjustment up from its lowest position.

If the Cutter Deck seems to require levelling first check these

other possible causes:

1. Are the tyres inflated correctly all round – if not, inflate to

the correct pressures.

2. Are the Cutter Deck Hanger Brackets (fig 2) moving

freely or are they hitching up. To check this lift the cutter

deck to its highest position and lift and rock it, watching to

ensure that the brackets move freely – if not clean and

grease.

3. Is the Front Axle pivoting freely? – If not, clean and oil.

4. Is there any impact damage that has bent or distorted the

Deck or Suspension Brackets (a matter for your dealer).

If the Deck is still uneven: -

LEVELLING FRONT TO BACK

(You need two people for this operation – one to lift the Deck

while the other removes or relocates the Trunnion)

1. Ensure that the Anti-Scalp Wheels are all adjusted in the

same hole – if not, rectify (fig 3).

2. Lower the Cutter Deck to a position one above the lowest

setting – check levels with the ruler or tape.

3. Now locate the front to back Adjustment Rod to the right

(offside) of the cutter. At the rear end of this Rod, near the

rear offside wheel, you will find the Trunnion (fig 2) that

links the rod to the Deck Hanger Bracket. Both the

Trunnion and the Rod are threaded and adjustment is

achieved by rotating the Trunnion to ‘in effect’shorten or

lengthen the Rod.

4. To free the Trunnion use a 9/16" spanner or socket to

remove the 3/8" Nyloc nut and washer and push it free.

5. Rotate the Trunnion to advance it up the Rod to lift the back

of the Deck. Rotate it the other way to lift the front.

Adjustment is rapid so try one or two turns and relocate the

Trunnion Bracket and secure – then check the effect. Repeat

and re-check if necessary.

TOOLS REQUIRED:

Steel Ruler or Tape

9/16” AF Socket

1/2” Spanner

1/2” Socket

13mm Spanner

13mm Socket

Reversible Ratchet

12” Extension Bar

fig 1

fig 2

fig 3

Front to Back

Adjustment Rod

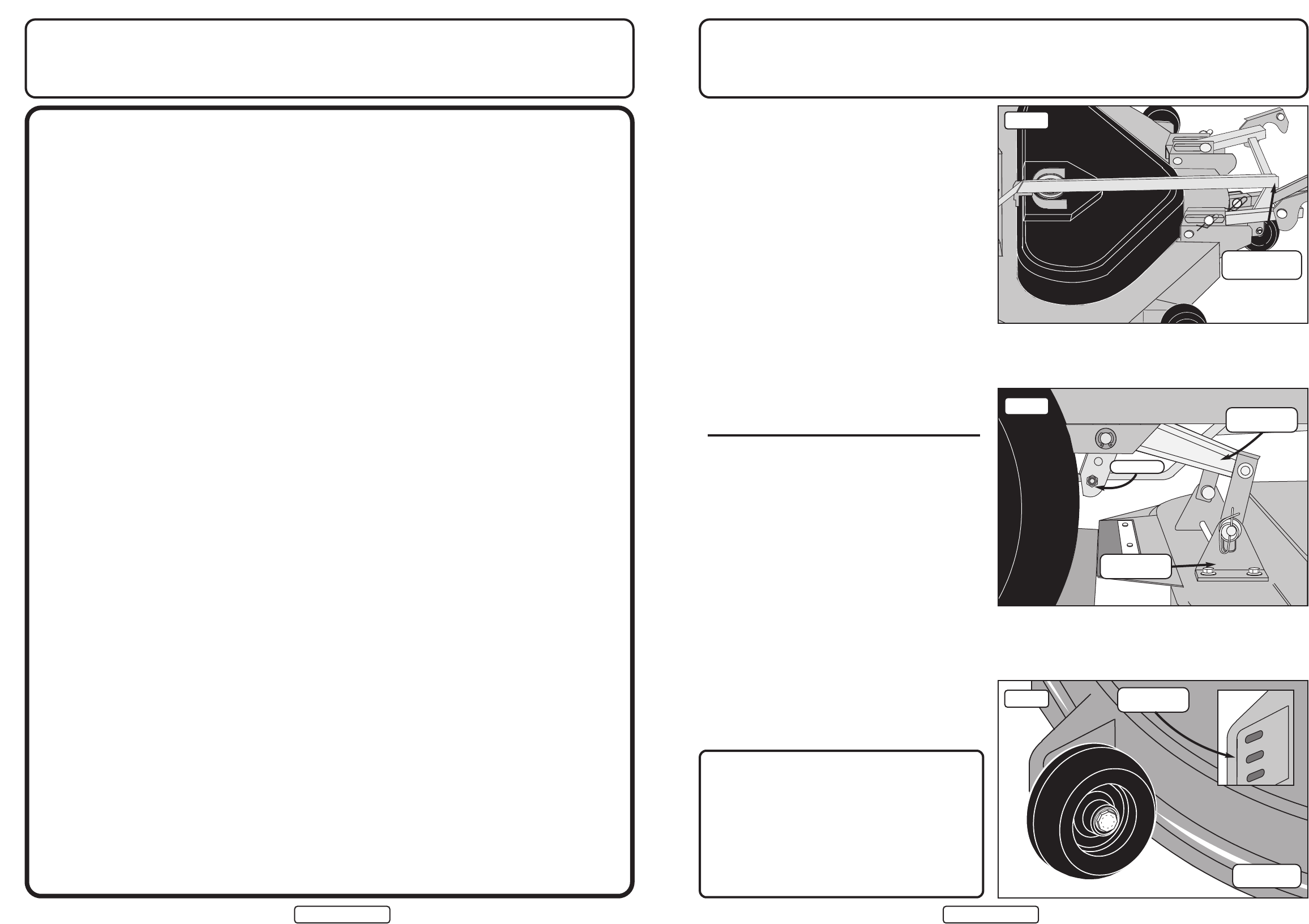

Countax Tractors are fitted with grassland tyres that are designed to present a

large area to the ground for grip; and are soft profile to prevent marking your

turf. They are of thicker section and tougher than most 4 ply tyres.

Persistent punctures and tyre deflation are nevertheless a problem experienced

by about 5% of Countax customers. This is not a problem just for Countax

owners – it is shared by the users of all types of off-road machinery fitted with

pneumatic tyres. In practically every case there is a common cause – THORNS!

Blackthorn, Hawthorn, and Rose are usually at the bottom of it and will

puncture any tyres not fitted with very expensive guards.

There are less expensive ways to overcome this problem – so check and avoid

these possible causes:

1. The rim of the wheel has become damaged –breaking the seal on the

tubeless tyre. There are two possible solutions:

* If the damage is not severe, treat with Countax tyre sealant (Pt No 52903501).

* If the damage is significant – order a new wheel

Front wheel - (Pt No 198000500)

Rear Wheel - (Pt No 198000700)

2. You have Hawthorn, Blackthorn, or Wild Rose in your hedges – these will

puncture any tyre. It makes sense to check any area you intend to cut or drive

over and to remove any branches.

The long-term solution is to treat all four tyres with Countax tyre sealant –

follow the instructions on the bottle.

IF YOUR TYRES SPIN OR LOSE GRIP CHECK:

1. Are the tyres correctly inflated –

• Front wheels 0.8Kgf/cm (12lb PSI)* to 1.1Kgf/cm (16lb PSI)

• Rear wheels 0.43Kgf/cm (6lb PSI)* to 0.7Kgf/cm (10lb PSI)

*Pressure recommended for maximum grip.

2. Are you in too high a gear for the conditions? If so, select a lower gear or

speed setting.

Deck Hanger

Bracket

Anti-Scalp

Wheels

Trunnion

Rear Deck

Cradle

Adjustment

holes