SEBU7858-03 31

Safety Section

Sound Information and Vibration Information

•

Jobsiteorgani

zation, preparation, environment,

weather, and material

•

Machine type,

quality of the seat, quality of the

suspension system, attachments, and condition of

the equipment

It is not possible to get precise vibration levels for

this machine. The expected vibration levels can be

estimated w

ith the information in Table 1 in order

to calculate the daily vibration exposure. A simple

evaluation of the machine application can be used.

Estimate the vibration levels for the three vibration

directions. For typical operating conditions, use the

average vi

bration levels as the estimated level. With

an experienced operator and smooth t errain, subtract

the Scenario Factors from the average vibration level

in order to

obtain the estimated vibration level. For

aggressive operations and severe terrain, add the

Scenario Factors to the average vibration level in

order to o

btain the estimated vibration level.

Note: All vibration levels are in meter per second

squared.

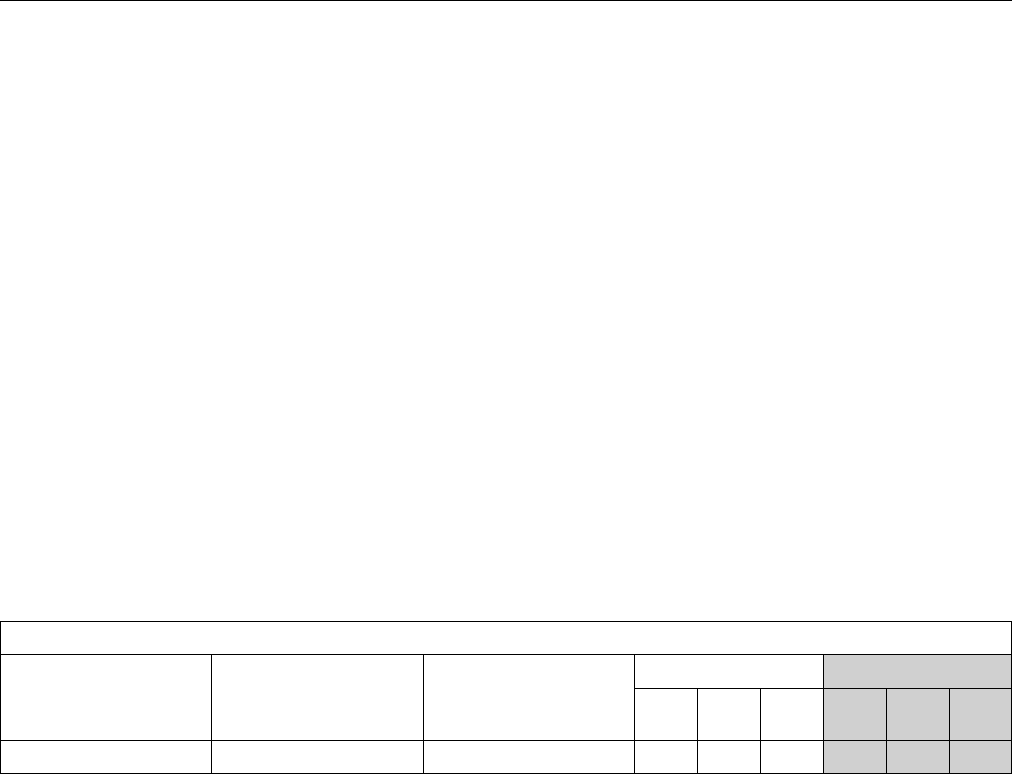

Table 1

“ISO Reference Table A - Equivalent vibration levels of whole body vibration emission for earthmoving equipment.”

Vibration Levels Scenario Factors

Machine Family Machine Type

Typical Operating

Activity

X

axis

Y

axis

Z

axis

X

axis

Y

axis

Z

axis

Scraper Wheel Scraper

work cycle 1,05 1,18 1,12 0,34 0,40 0,42

Note: Refer to “ISO/TR 25398 Mechanical Vibration -

Guideline for the assessment of exposure to whole

body vibration of ride on operated earthmoving

machines” for more information about vibration.

This publication uses data that is measured

by international institutes, organizations and

manufacturers. This document provides information

about the whole body exposure of operators of

earthmoving equipment. Refer to Operation and

Maintenance Manual, SEBU8257, “The European

Union Physical Agents (Vibration) Directive

2002/44/EC” for more information about machine

vibration levels.

The Caterpillar suspension seat meets the criteria of

“ISO 7096”. This represents vertical vibration level

under severe operating conditions. This seat is tested

with the input “spectral class EM2”. The seat has a

transmissibility factor of “SEAT<1.0”.

The whole body vibration level of the machine varies.

There is a range of values. The low value is 0.5

meter per second squared. The machine meets the

short term level for the design of the seat in “ISO

7096”. The value is 1.34 meter per second squared

for this machine.

Guidelines for Reducing Vibration Levels on

Earthmoving Equipment

Properly adjust machines. Properly maintain

machines. Operate machines smoothly. Maintain the

conditions of the terrain. The following guidelines can

help reduce the whole body vibration level:

1. Use the right type and size of machine, equipment,

and attachments.

2. Maintain machines according to the manufacturer's

recommendations.

a. Tire pressures

b. Brake and steering systems

c. Controls, hydraulic system and linkages

3. Keep the terrain in good condition.

a. Remove any large rocks or obstacles.

b. Fill any ditches and holes.