SEBU7858-03 19

Safety Section

General Hazard Information

Obey all local r

egulations for the disposal of liquids.

Use all cleaning solutions with care. Report all

necessary rep

airs.

Do not allow unauthorized personnel on the

equipment.

Unless you are instructed otherwise, perform

maintenanc

e with the equipment in the servicing

position. Refer to Operation and Maintenance Manual

for the procedure for placing the equipment in the

servicing p

osition.

When you perform maintenance above ground level

use approp

riate devices such as ladders or man lift

machines. If equipped, use the machine anchorage

points and use approved fall arrest harnesses and

lanyards.

Pressuri

zed Air an d Water

Pressurized air and/or water can cause debris

and/or ho

t water to be blown out. This could result in

personal injury.

When pre

ssurized air and/or pressurized water is

used for cleaning, wear protective clothing, protective

shoes, and eye protection. Eye protection includes

goggles

or a protective face shield.

The maximum air pressure for cleaning purposes

must be

reduced to 205 kPa (30 psi) when the

nozzle is deadheaded and the nozzle is used with

an effective chip d eflector and personal protective

equip

ment. The maximum water pressure for

cleaning purposes must be below 275 kPa (40 psi).

Tr apped Pressure

Press

ure can be trapped in a hydraulic system.

Releasing trapped pressure can cause sudden

machine movement or attachment movement. Use

caut

ion if you disconnect hydraulic lines or fittings.

High pressure oil that is released can cause a hose to

whip. High pressure oil that is released can cause oil

to sp

ray. Fluid p enetration can cause serious injury

and possible death.

Fluid Penetration

Pre

ssure can be trapped in the hydraulic circuit long

after the engine has been stopped. The pressure can

cause hydraulic fluid or items such as pipe plugs to

es

cape rapidly if the pressure is not relieved correctly.

Do not remove an

y hydraulic components or parts

until pressure has been relieved or personal injury

may occur. Do not disassemble any hydraulic

components or

parts until pressure has been relieved

or personal injury may occur. Refer to the Service

Manual for any procedures that are required to

relieve the h

ydraulic pressure.

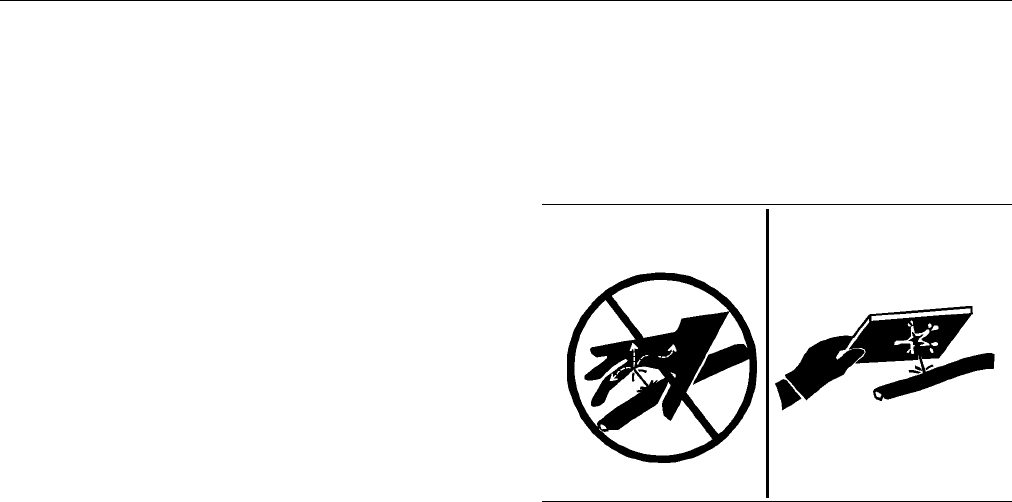

g00687600

Illustration 20

Always use a board or cardboard when you check

for a leak. Leaking fluid that is under pressure can

penetrate body tissue. Fluid penetration can cause

serious injury and possible death. A pin hole leak can

cause severe injury. If fl uid is injected into your skin,

you must get treatment immediately. Seek treatment

from a doctor that is familiar with this type of injury.

Containing Fluid Spillage

Care must be taken in order to ensure that fluids

are contained during performance of inspection,

maintenance, testing, adjusting and repair of the

equipment. Prepare to collect the fluid with suitable

containers before opening any compartment or

disassembling any component that contains fluids.

Refer to Special Publication, NENG2500, “Caterpillar

Dealer Service Tool Catalog” for the following items:

•

Tools that are suitable for collecting fluids and

equipment that is suitable for collecting fluids

•

Tools that are suitable for containing fluids and

equipment that is suitable for containing fluids

Obey all local regulations for the disposal of liquids.