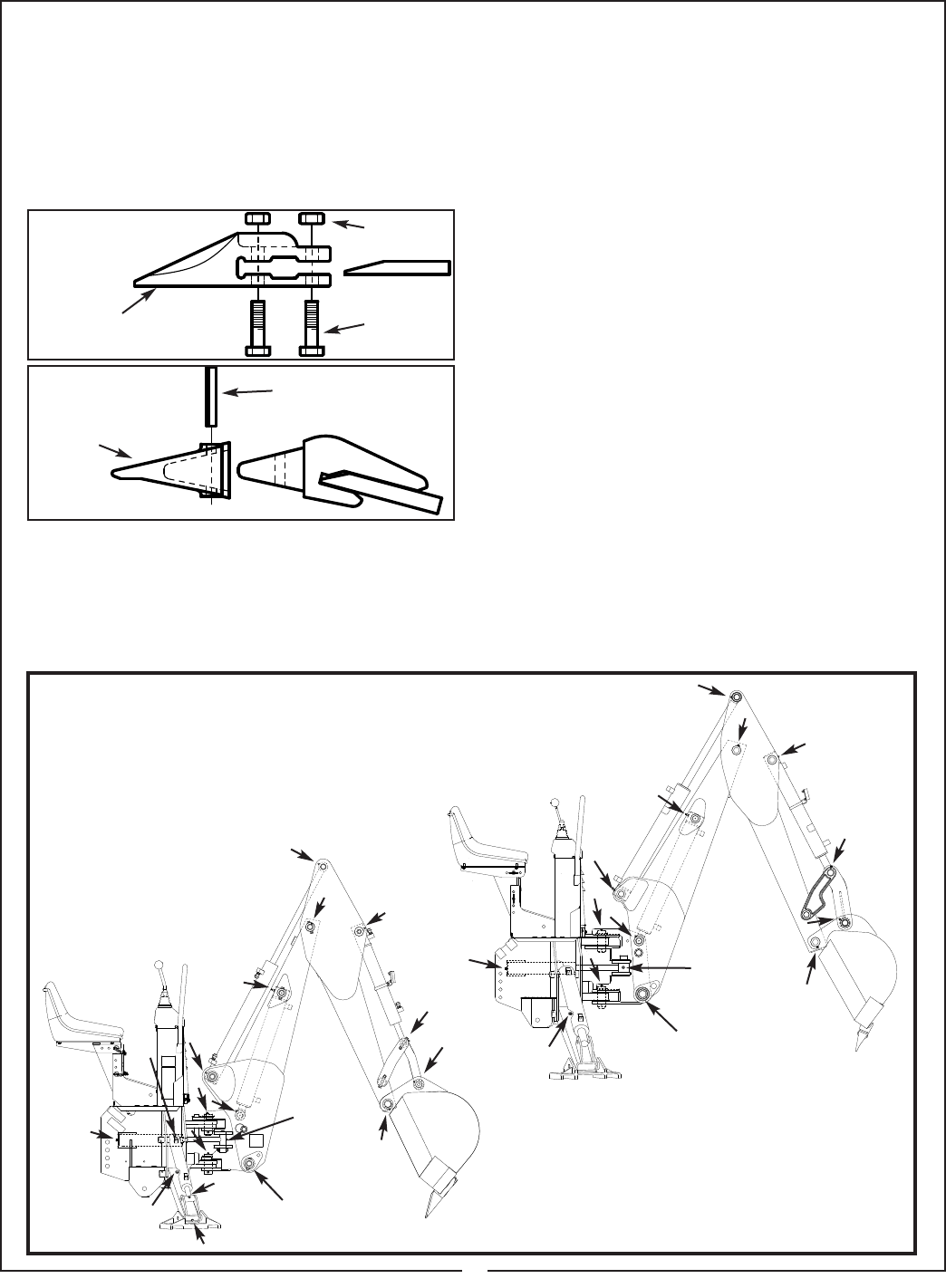

TOOTH REPLACEMENT

Bolt-On tooth points, when worn, can be replaced by

removing the hardware that connects it to the cutting

edge. Install new tooth and replace hardware if nec-

essary. (Figure 5)

Roll-Pinned tooth points, when worn, can be replaced

by driving out the roll pin with a hammer and punch.

Install the new tooth using a new roll pin and hammer.

(Figure 6)

Economical and efficient operation of the backhoe is

dependent upon regular and proper lubrication of all

moving parts with a quality lubricant.

All parts provided with grease fittings should be lubricat-

ed with a good quality chassis lube type grease. If any

grease fittings are missing, replace them immediately.

Clean all fittings thoroughly before using grease gun.

Lubricate all grease fittings at least twice daily, once

at the beginning of operation and again approximate-

ly halfway through the work day.

Lower stabilizers to the ground and lower boom so

bucket rests on the ground as shown in Figures 7

and 8. Refer to these illustrations for the location of

all grease fittings.

IMPORTANT: Before greasing boom to swing

frame pivot (*) shown in Figures 7 and 8, raise

boom and install transport lock pin shown in

Figure 1.

On Models BH650, BH750, BH850 and BH950 the

following locations should be oiled with SAE30 oil:

A. All Control Handle Linkages

B. Seat Bracket Pivot

15

Figure 6

Roll-Pin Tooth

LUBRICATION

IMPORTANT: Avoid excessive greasing. Dirt collects on

exposed grease and increases wear greatly. After greas-

ing, wipe off excessive grease from

fittings.

Figure 5

Bolt-On Tooth

Nut

Bolt

Point

Point

Roll-Pin

Figure 7 Lubrication Points

BH650 & BH750

Tightening Nuts and Bolts

Periodically, check to be sure all bolts and nuts are

tight. See torque chart, page 45 .

Check all pivot pins for cotter pins, washers and

retainers; if missing, replace.

Figure 8 Lubrication Points

BH850 & BH950

(3)

(3)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

*

*