19

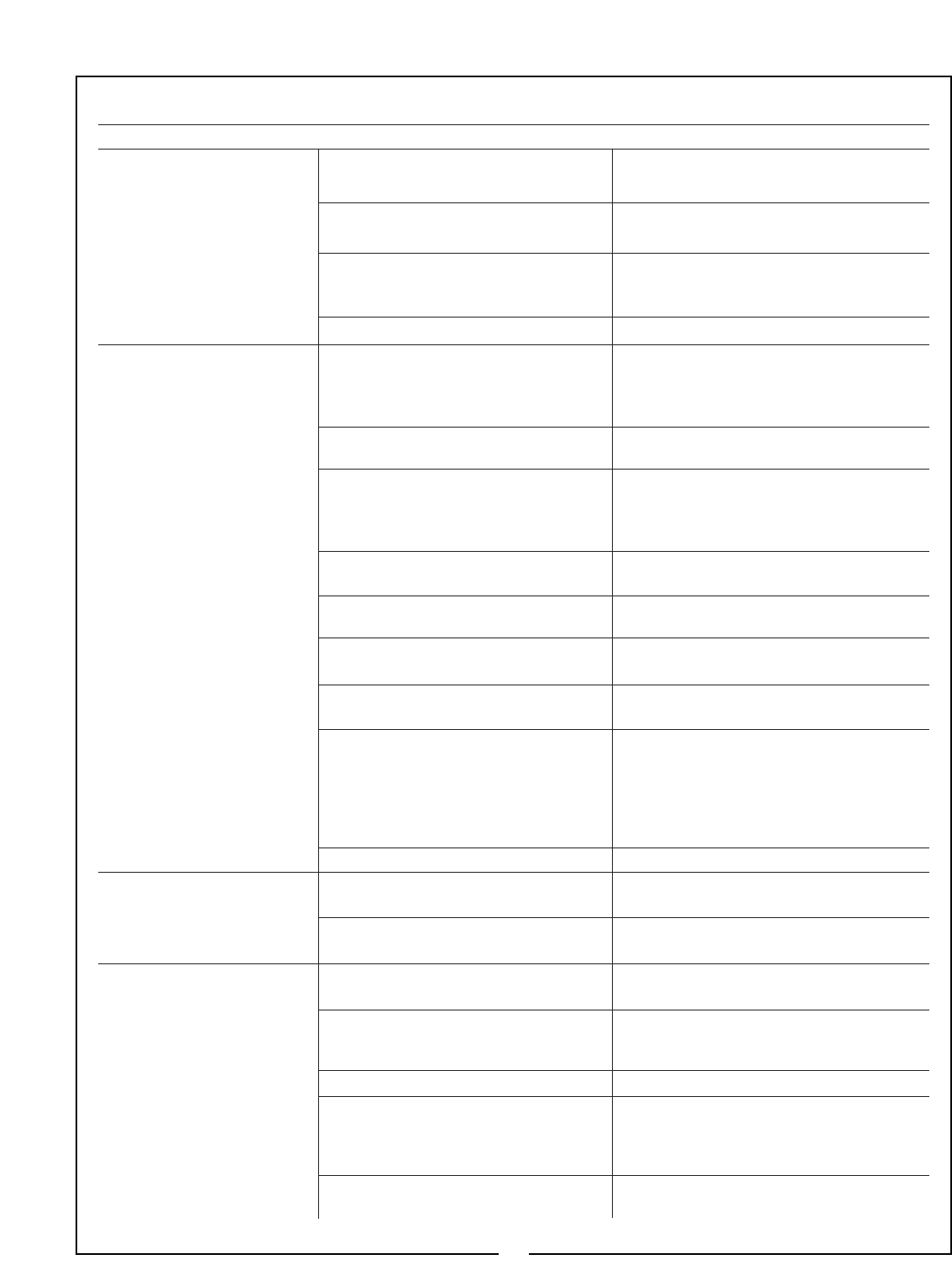

Troubleshooting (Continued)

Problem Cause Correction

Loss of power in any one Worn or damaged rod seals on Repack cylinder. Rebuild cylinder,

cylinder, including lift cylinder; external leaks replacing damaged parts as necessary.

and crowd

Spool not moved to full stroke Check spool travel - should be .26”

either way, or a total of .52”.

Overload relief valve in the control Clean relief carefully but do not disturb

valve stuck open or malfunctioning its pressure setting as it cannot be field

calibrated, or replace cartridge.

Worn control valve Replace the control valve.

Loss of power in swing Loose oil line connections, Tighten all hose connections and

cylinders, but other leaks in line or broken lines replace any damaged O-rings at

cylinders functioning leaking O-ring fittings. Check and

properly. replace any damaged hoses and lines.

Restrictions in oil lines Check and replace any damaged hoses

and lines. Check for pinched hoses.

Oil is bypassing cylinder piston, Replace or rebuild the cylinder; replace

scored piston, worn piston damaged parts.

packing, or defective piston

assembly

Scored piston rods and worn Replace or rebuild the cylinder; replace

guides in cylinder damaged parts.

Bent piston rod in cylinder Replace or rebuild the cylinder; replace

damaged parts.

Worn or damaged rod seals on Repack cylinder. Rebuild cylinder,

cylinder; external leaks replacing damaged parts as necessary.

Spool not moved to full stroke Check spool travel - should be .26”

either way, or a total of .52”.

Relief valve setting in backhoe Relief pressure will have to be checked

control valve too low or defective and corrections made. Backhoe

system pressure is 2400 PSI. Relief

valve may need cleaning and over

hauling, or entire cartridge must be

replaced.

Worn control valve Replace the control valve.

Maximum swing action Bent piston rod in cylinder Replace or rebuild the cylinder; replace

cannot be obtained damaged parts.

Something jamming the swing Remove interference.

linkage

Slow operation of machine

(lack of power) all cylinders Low oil supply in reservoir Fill to proper level.

Oil viscosity too heavy, or oil Use recommended hydraulic fluid. Run

is not at operating temperature machine until oil reaches operating

temperature.

Insufficient pumping Advance engine throttle.

Diverter valve on prime mover Diverter valve may need rebuilding or

leaking externally or bypassing replacing.

oil internally through valve to

reservoir

Excessive back pressure Relieve condition. Restriction may be

from outlet to reservoir.