11

• Place the saw on a firm surface. Rotate the two allen head screws

(11) counterclockwise with the wrench (13) provided as shown in

figure D.

• To remove the saw chain (9), rotate the tension adjustment screw

(23) in the front of the housing using the flat screwdriver end of the

wrench (13) as shown in figure F. Turning the screw

counterclockwise allows the guide bar to recede and reduces the

tension on the chain so that it may be removed.

• Remove sprocket cover (10) and

allen head screws (11).

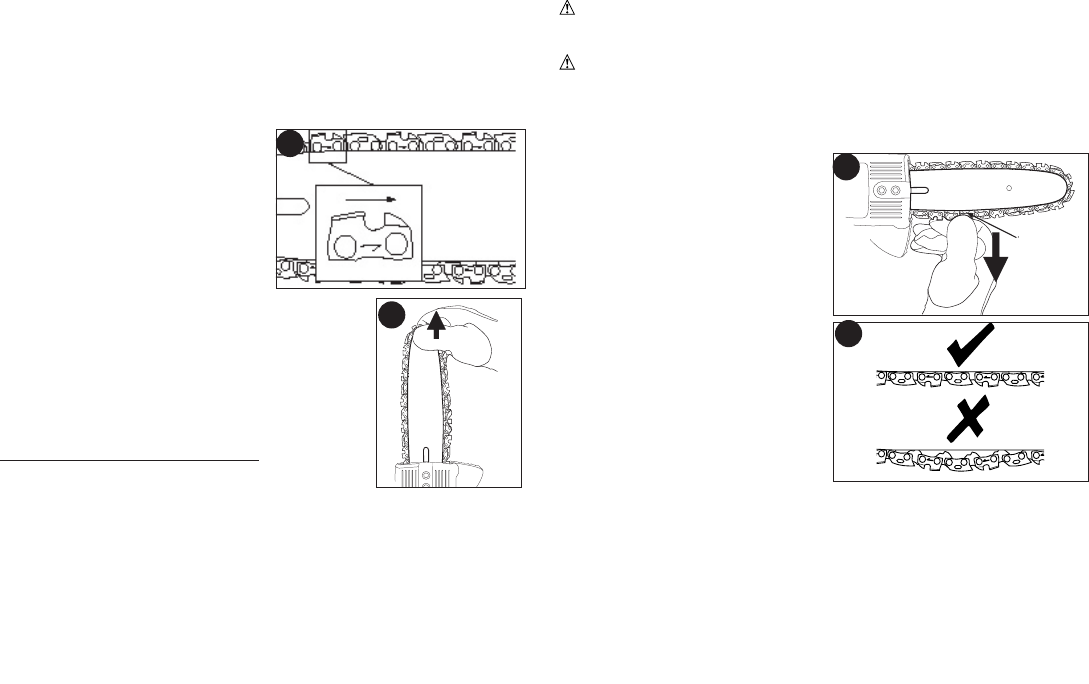

• Lift the worn saw chain (9) out of

the groove in the guide bar (8).

• Place new chain in groove of guide

bar making sure saw teeth are

facing correct direction by

matching arrow on chain with

graphic on housing shown in

figure G.

• Place the saw chain and guide bar assembly

around the sprocket (19). Check to make sure

that the slot (20) in the guide bar (8) is over the

two location pins (21) shown in figure E and

that the hole below the slot is located over the

adjustment pin (22).

• Replace sprocket cover (10) and thread allen

head screws (11) in with wrench until snug,

then back wrench off one full turn

.

• Pull bar nose up and keep it up as you adjust

tension Figure G1.

• Rotate the tension adjustment screw (23) in the front of the housing

clockwise to increase the chain tension as in Figure F.

• Follow instructions in “Adjusting Chain Tension” section.

• While still holding the bar nose up, securely tighten the rear allen

screw (11) first, then tighten the front allen screw.

• When the chain is new check the tension frequently (after

disconnecting battery) during the first 2 hours of use as a new chain

stretches slightly.

Adjusting Chain Tension

CAUTION: Sharp chain. Always wear protective gloves when

handling the chain. The chain is sharp and can cut you when it is

not running.

WARNING: Sharp moving chain. To prevent accidental

operation, insure that battery is disconnected from the tool

before performing the following operations. Failure to do this

could result in serious personal injury.

• With the saw still on a firm surface check the chain tension. The

tension is correct when the chain

snaps back after being pulled 1/8

inch (3mm) away from the guide

bar (8) with light force from the

middle finger and thumb as

shown in figure H. There should

be no “sag” between the guide

bar and the chain on the

underside as shown in figure I.

• To adjust saw chain tension,

loosen the allen head screws

(11).

• Rotate the tension adjustment

screw (23) in the front of the

housing using the flat

screwdriver end of the wrench

(13) as shown in figure F.

• Do not over-tension the chain as

this will lead to excessive wear

and will reduce the life of the bar and chain. Overtensioning also

reduces the amount of cuts you will get per battery charge.

• Once chain tension is correct, tighten allen head screws (11).

• When the chain is new check the tension frequently (after

disconnecting battery) during the first 2 hours of use as a new chain

stretches slightly.

G

H

I

1/8 in.

(3mm)

G1