Part No. 890604 Form No. F021602C

Page 9 of 12

MAINTENANCE continued

IMPELLER REMOVAL continued

18. If chipper blade properly clears anvil surface, proceed to step .

If not, return to (step 14) and add or subtract shim washers as

needed to obtain a correct gap.

19. Reinstall engine and impeller onto housing in reverse order

of removal.

20. Before connecting spark plug wire, slowly pull engine

starting rope to insure that impeller rotates freely.

21. Reinstall spark plug wire.

fig. 7

17

Engine (See Engine Manual)

Check for excessive vibration

Clean Debris Bag

Check bag strap tightness

Inspect for loose parts

Maintenance Operation

Follow these hourly

maintenance intervals.

Maintenance Schedule

Inspect for worn or damaged parts

Every 5 hrs

or (Daily)

Every

Use

17.2

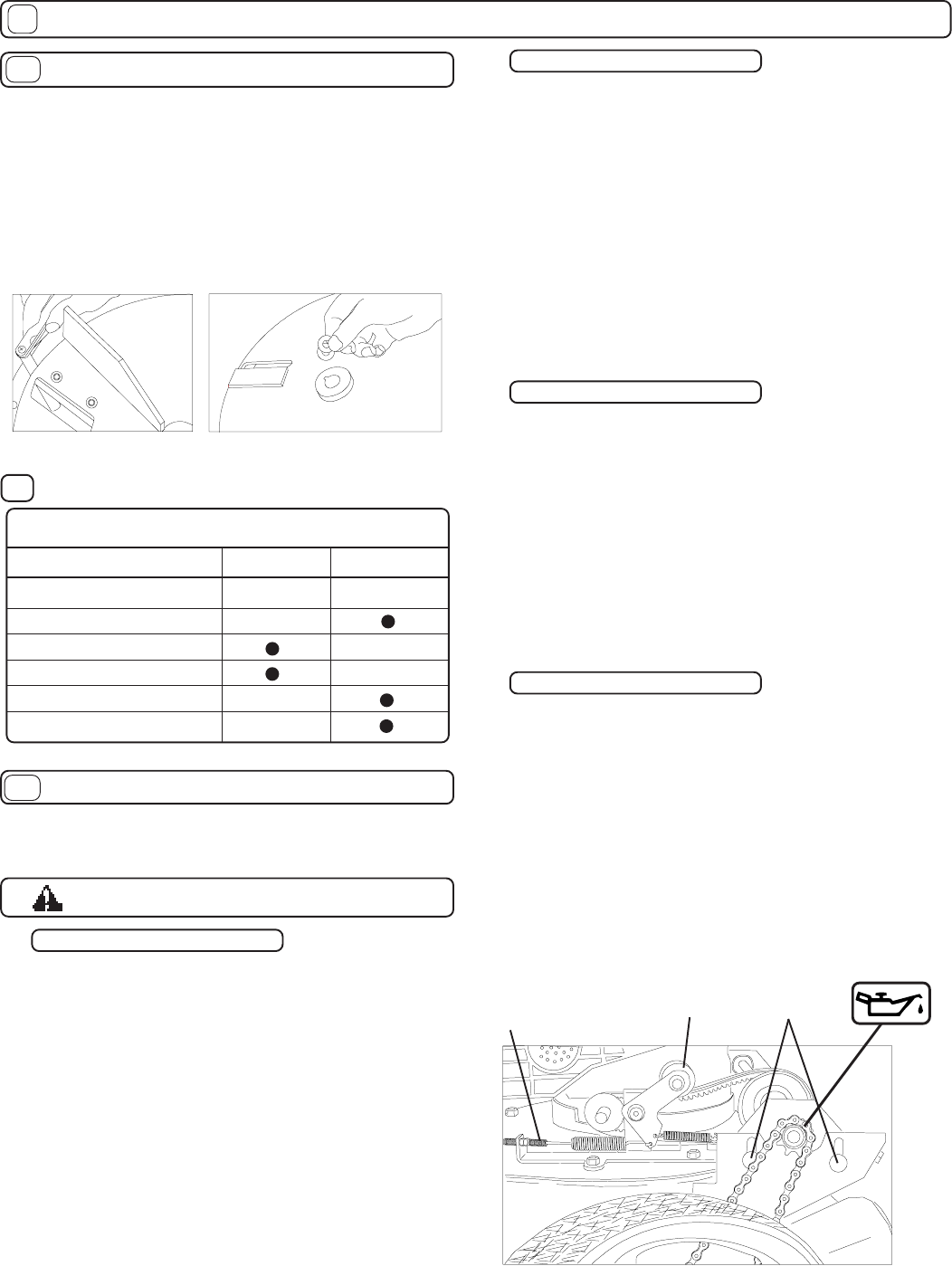

Threaded

Adjuster

Carriage

Bolt

Idler

Pulley

CLUTCH ADJUSTMENT

INSPECTING DRIVE

CHAIN ADJUSTMENTS

DRIVE

Chains are normal replaceable wear items. A new chain

should not be used on worn sprockets. Sprockets should

be replaced when replacing chains.

Stop engine and disconnect spark plug

wire before making adjustments.

17.3

17.1

fig. 6

1. Remove chain guard

2. Inspect chains, sprockets, belt, and pulleys for wear and

replace as required

3. Inspect chains for lubrication and lubricate as required

4. Check chain tension. A properly tensioned chain will

deflect about 1/8” midway between the sprockets when

light and pressure is applied. If adjustment is required see

Replacing and adjusting chairs.

5. Check clutch adjustment. When properly adjusted,

operating the clutch at the handle will move the idler pulley

down such that a gap of 5/8”-3/4” is left between the inside

halves of the belt. Worn belt or pulleys can give the

appearance of clutch mis-adjustment. Replace any worn

components. If adjustment is required see Adjusting

clutch cable.

6. Replace guard after inspection.

CHAIN REPLACEMENT

When replacing always replace both chains even if only one

appears worn.

1. Remove chain guard

2. Loosen (4) carriage bolts that hold the jackshaft bearings in

place.

3. Slide the jackshaft down and back toward the engine to

loosen the chains.

4. Remove nuts that hold the front wheels.

5. Slip chains off the small sprockets on the jackshaft and slide

the wheel and chain off each side.

6. Replace the chains on the wheels and reinstall them on the

axles.

7. Slip chains over the small sprockets on the jackshaft.

8. Adjust chains for proper tension (see below)

9. Check clutch for proper operation and adjust if required.

1. Loosen (4) carriage bolts that hold jackshaft bearing on

place.

2. Pull up on jackshaft to draw chains tight

3. While holding chains tight rotate the jackshaft back toward

the engine slightly so that there is no tension on the belt.

NOTE: If the jackshaft is set too far forward the belt will not

clutch or release properly during use.

4. With jackshaft properly positioned tighten (4) carriage bolts to

lock it in place.

5. Rotate wheels by hand and check chain tension and align-

ment.

6. Readjust as required.

7. Replace guard.

1. Remove guard.

2. To increase belt tension (drive will not engage) loosen jam

nuts that hold the treaded adjuster on the clutch cable.

3. Slide the adjuster toward the rear of the unit about ¼” and

retighten the jam nuts, to secure it in place.

4. Test clutch operation and readjust as required

5. To decrease belt tension (drive will not disengage or free

wheel) loosen jam nuts that hold the treaded adjuster on the

clutch cable.

6. Slide the adjuster toward the front of the machine about ¼”

and retighten the jam nuts to secure the cable in place.

7. Test clutch operation and readjust as required.

8. If unit will not free wheel with clutch disengaged loosen (4)

carriage bolts and slide the jackshaft back 1/8” and retighten

carriage bolts.