GB - 27

8. Remove cap screws securing housing to

frame (one on each side). Tip housing

and frame apart on pivot pins (Figure 20).

9. Remove attachment drive belt from

attachment pulley (hold brake away from

belt).

Install new attachment drive belt:

1. Place new attachment belt onto

attachment pulley.

2. Tip housing and frame back together and

secure with cap screws.

3. Place belt onto engine sheave.

4. Make sure engine sheave and attachment

pulley align. If alignment is necessary,

loosen attachment pulley set screws,

reposition pulley and retighten set screws.

5. Reposition and secure belt fingers.

IMPORTANT: Make sure belt fingers are

1/16 in. to 1/8 in. (1.6-3mm) from belt when

attachment clutch is engaged.

6. Check adjustment. See Attachment

Clutch/Brake.

7. Reconnect chute crank and secure with

spring clip. If equipped, reconnect remote

cap deflector cable and/or electric chute

wire harness.

8. Replace belt cover.

TRACTION DRIVE BELT

REPLACEMENT

NOTE: Housing and frame must be tipped

apart and attachment drive belt removed from

engine sheave in order to change traction

drive belt.

1. Remove attachment drive belt (see

Attachment Drive Belt Replacement).

2. Pull idler away from traction drive belt and

remove belt from idler pulley, engine

sheave and driven pulley (it may be

necessary to turn engine pulley using

recoil handle).

NOTE: To gain clearance, engage traction

clutch and if necessary pull back attachment

idler arm clevis pin.

3. Install new traction drive belt onto

attachment pulley and engine sheaves.

4. Replace attachment drive belt (See

Replace Attachment Drive Belt).

FRICTION DISC REPLACEMENT

1. Place unit into service position.

2. Remove bottom cover by removing four

cap screws.

3. Place speed selector in first (1) position

and depress traction clutch lever to hold

friction disc and hub in position.

4. Remove cap screws from hub

(Figure 22).

5. Release traction clutch lever, shift to third

(3) position, and remove friction disc.

6. Secure new friction disc on hub with five

cap screws and torque cap screws to

8-10 lbf-ft (10,6-13,3 N•m).

7. Replace bottom cover.

8. Adjust traction drive clutch (see Traction

Drive Clutch Adjustment).

CAUTION: Always support Sno-Thro

frame and blower housing when

loosening the cap screws holding

them together. Never loosen cap

screws while unit is in service

position.

WARNING: AUGER / IMPELLER

MUST STOP within 5 seconds when

attachment clutch lever is released or

unit damage or serious injury may

result.

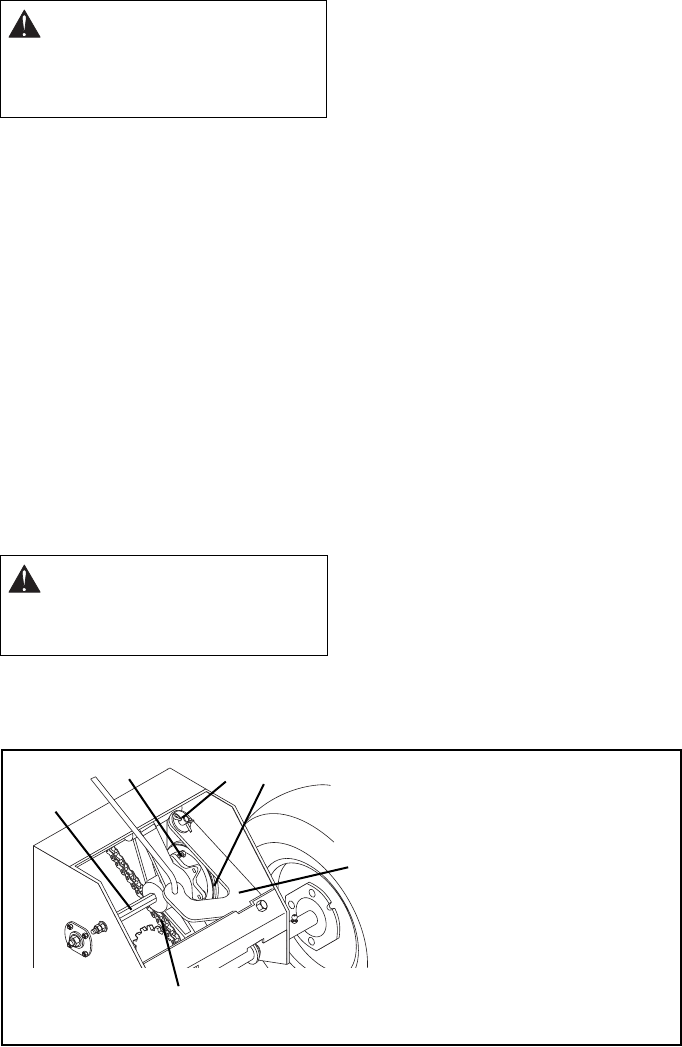

1

2

3

4

5

Figure 22

6

OS0612

1.Cap Screw

2.Cotter Pin

3.Friction Disc

4.Shift Arm

5.Chain

6.Idler Hex Shaft