4 - 15

For Replacement:

1. Slide auger outward against roll pin and align hole

in shaft with hole in auger. The holes in the shaft

for the roll pins and Shear Bolts line up.

2. Drive Shear Bolt through hole (if Shear Bolt was

broken this will drive the remaining part from shaft).

3. Secure Shear Bolt with nut.

4. The Shear Bolts should not be overtightened to

collapse the auger center tube to the auger drive

shaft.

4.11 TIRE PRESSURE

Maintain the unit tire pressure at a maximum of

20 PSI (138 kPa).

4.12 ADJUSTMENTS

Discharge Chute Deflector

To adjust the drag force, loosen or tighten the two bolts

to accomplish the desired drag.

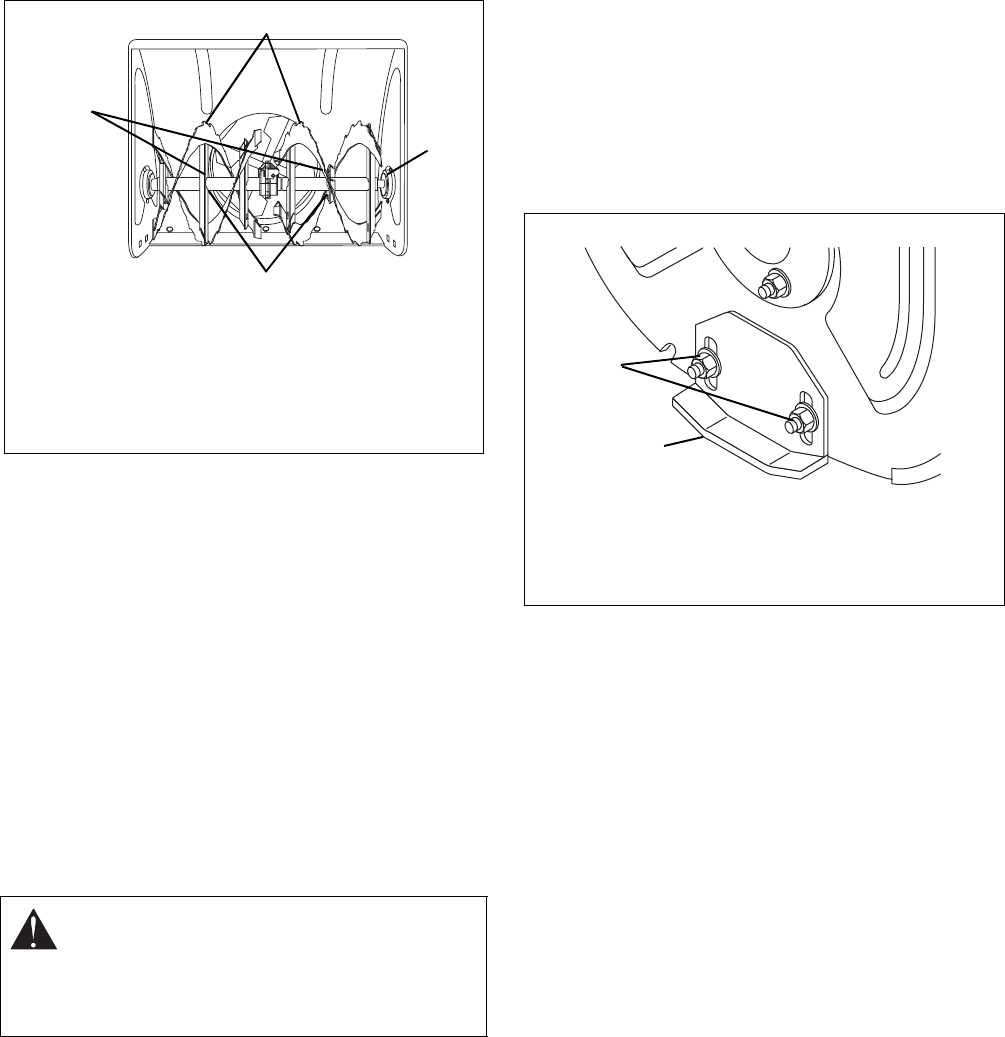

Runners

Runners should be adjusted as conditions require.

Raising or lowering runners controls distance scraper

blade (auger/impeller housing) is held above surface

being cleared.

1. Position unit on a hard, flat smooth level surface.

2. Adjust runners by inserting a spacer of desired

thickness under center of scraper blade, loosen

runner hardware, slide runners to flat surface

(Figure 7). Allow 1/8" (3 mm) between scraper

blade and hard smooth surface. Allow 1-1/4"

(30 mm) minimum between scraper blade and

uneven surface(s).

3. Retighten hardware.

NOTE:

Keep housing level by adjusting runners

equally. Uneven runners make unit difficult to steer and

results in uneven clearing.

Scraper Blade

IMPORTANT:

Damage to auger/impeller housing will

result if blade wears down too far.

Scraper blade is adjustable to compensate for wear.

To adjust scraper blade:

1. Tip unit back onto handlebar. Support the housing

and loosen scraper blade nuts. With runners

adjusted to their full up position, reposition scraper

blade down, flush with runners. Tighten lock nuts.

Readjust runners if necessary.

Discharge Chute

If chute does not stay in position while operating,

tighten nut on carriage bolt at pivot point to increase

tension on spring (Figure 8).

Smooth and easy rotation of properly lubricated chute

with crank (without binding) is obtained by adjusting

pinion and flat gear teeth so they mesh together.

Adjust, using adjustment slots in pinion bracket which

is secured to chute strap.

WARNING:

ACCIDENTAL ENGINE START

UP can cause death or serious injury.

ALWAYS stop engine, remove key, wait for

moving parts to stop and remove wire from

spark plug before adjusting or servicing.

OS0401

1. Auger

2. Roll Pin

3. Shear Bolt(s)

4. Nut(s)

2

3

4

Figure 6

1

1

2

1. Runner

2. Runner Hardware

OS0480

Figure 7