9 - 40

9.1 INTRODUCTION

NOTE:

Rear wheels must be removed to perform

repairs in this section. Block up rear of mower to raise

rear wheels off work surface. Remove snap ring secur-

ing wheel to axle and remove washer and wheel.

9.2 GEAR REMOVAL

Remove snap ring securing gear cover over idler shaft,

remove taptites securing cover to drive mount, and

remove gear cover.

Slide differential assembly off axle and remove idler

gear from idler shaft.

Drive out roll pin securing pinion gear on hex shaft and

remove pinion gear.

Inspect parts for wear and or damage, replace as

necessary. Assemble in reverse order and grease

spline area.

9.3 AXLE REMOVAL

Remove snap ring next to axle spline on left side of

axle and remove axle bearing.

Remove cotter pin securing left side of rear protective

guard to bracket and move guard out of the way.

With snap ring pliers, spread snap ring apart on right

side of axle. Pull right wheel and axle from mower until

left end of axle clears drive mount.

Inspect parts for wear and or damage, replace as

necessary and assemble in reverse order being sure to

grease spline area.

9.4 DRIVE MOUNT REMOVAL

Remove axle and gears. Refer to Axle Removal and

Gear Removal Sections.

Remove extension spring from drive actuator. Loosen

nuts securing drive cable to drive actuator. Remove

drive cable spring from bracket on mower pan and

remove drive cable from drive actuator.

Remove cotter pin and washer from shift link. Remove

shift link, and drive mount.

Assemble in reverse order.

9.5 DRIVE MOUNT DISASSEMBLY

Drive out roll pin in hex shaft and remove hex shaft.

Press out bearings from drive mount with bearing

driver.

Remove taptites securing retainer plate to drive mount

and remove guide shaft.

Push idler shaft out of drive mount, inspect parts for

wear or damage and replace as necessary. Assemble

in reverse order.

9.6 FRICTION WHEEL REPLACEMENT

If rubber tire on friction wheel becomes worn, chipped,

or broken, friction wheel must be replaced.

On models with steel friction wheel hub and 3 retaining

screws, remove the three cap screws and nuts that

secure friction wheel to hub (hole in bearing plate

provides access to hardware) and remove friction

wheel.

WARNING:

Remove wire from spark plug

before attempting any repair or adjustment

procedures.

WARNING:

Gasoline is highly flammable and

its vapors are explosive. Handle with care.

CAUTION:

DO NOT touch engine or parts

which are hot from operation. Allow such

parts to cool before servicing unit.

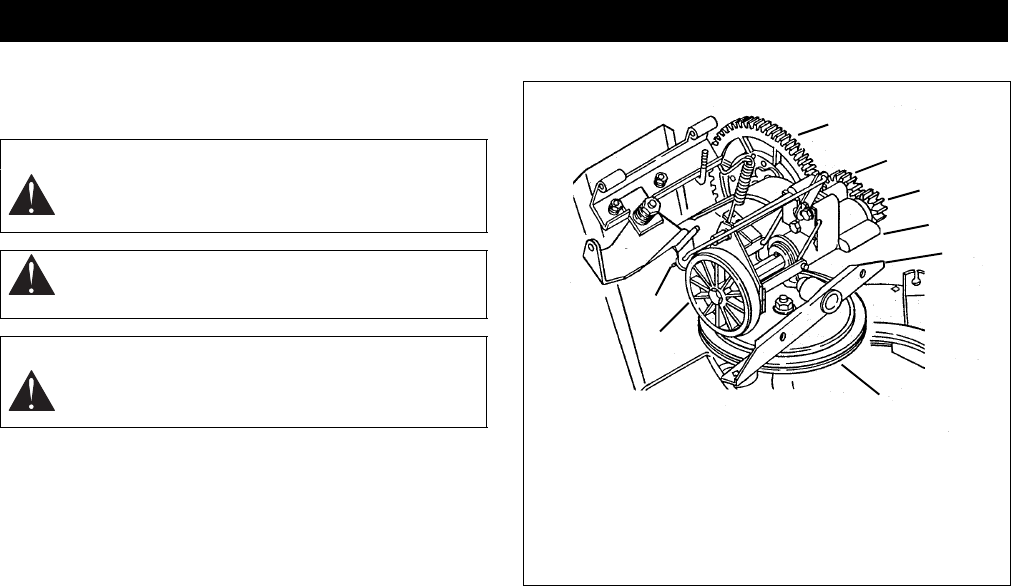

SECTION 9 - FRICTION DRIVE SYSTEM & AXLE

Figure 27

1. Differential

2. Idler Gear

3. Pinion Gear

4. Drive Carrier

5. Pivot Channel

6. Drive Disk

7. Friction Wheel

8. Shift Link

1

2

3

4

5

6

7

8