9

CHECK FOR LOOSE FASTENERS

1. Beforeeachusemakeathoroughvisualcheckofthe

spreaderforanyboltsandnutswhichmayhaveloosened.

Retightenanylooseboltsandnuts.

CHECK FOR WORN OF DAMAGED PARTS

2. Checkforwornordamagedparts beforeeachuse.

Repair or replace parts if necessary.

CHECK TIRE INFLATION

3. Checkiftiresareadequatelyinatedbeforeeachuse.Do

notinatebeyondmaximumrecommendedpressure.

CLEANING

FIGURE 14

1. Rinseinsideofhopperandexteriorofspreaderanddry

offbeforestoring.

2. Storeinaclean,dryarea.

CAUTION: DO NOT inatetiresbeyondthe

maximum recommended pressure printed

on side of tire.

4. Rinseinsideofhopperandexteriorofspreaderanddry

offbeforestoring.

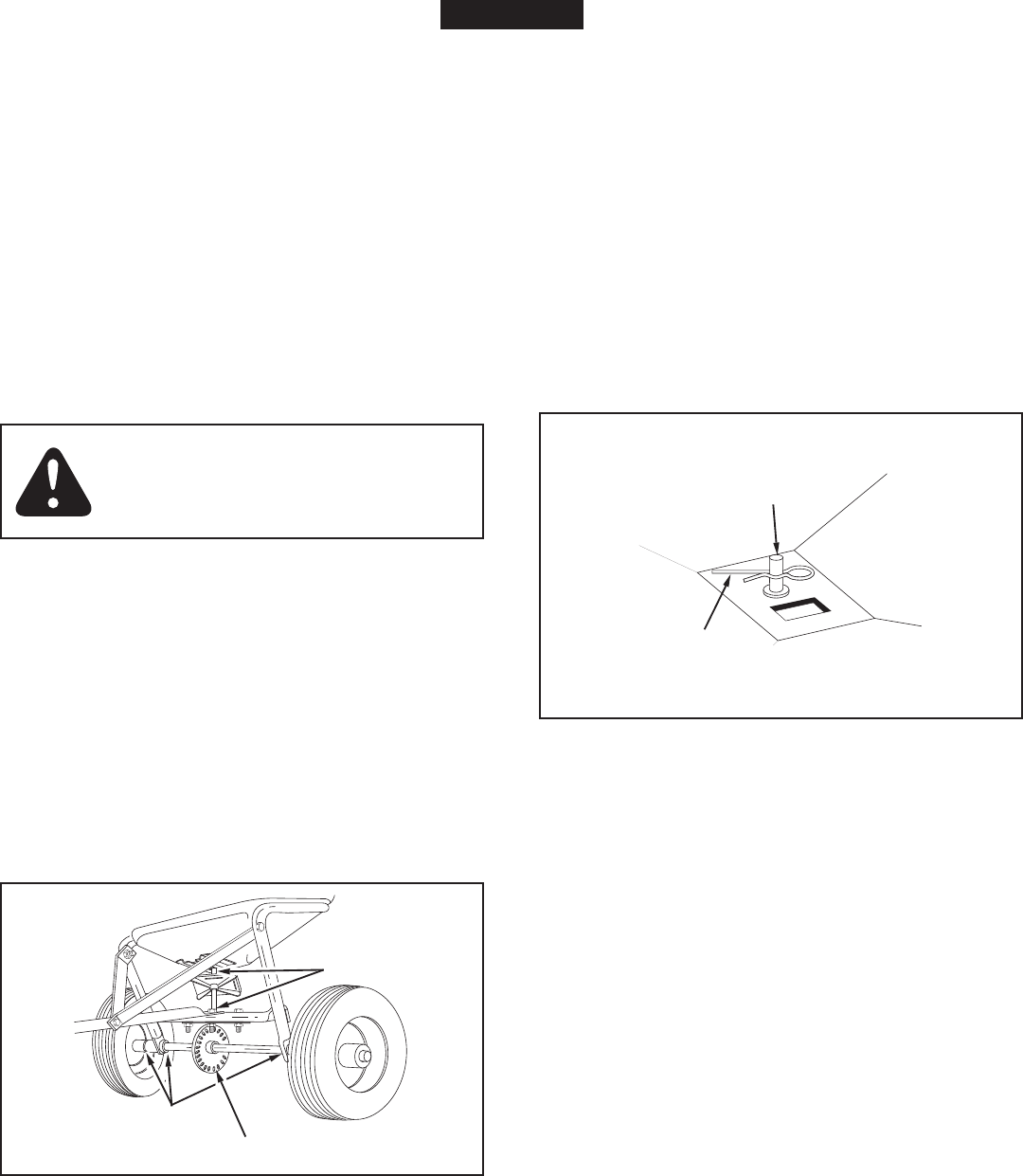

LUBRICATE (Seegure14.)

5. Lightly apply automotive grease as needed to the

sprocketandgear.

6. Oilthenylonbushingsontheverticalsprocketshaft

andontheaxleatleastonceayear,ormoreoftenas

needed.

7. Oilrighthand(idler)wheelbearingatleastonceayear

or more often as needed.

FIGURE 15

MAINTENANCE

GREASE

OIL

OIL

STORAGE

1. If the axle, slotted gear and sprocket assembly is

disassembled,markdownthepositionsofthepartsas

theyareremoved.Thedrivewheelandsprocketpositions

inrelationtotheslottedgeardeterminewhichdirection

thespreaderplatewillspin.Besuretoreassemblethem

intheiroriginalpositions.(Refertogure4onpage5.)

Useshimwashers(Ref.no.21onpages18and19)

asneededforminimumbacklash.Addgreasetogear

andsprocket.

2. Iftheagitatorhairpinbecomesdamagedorwornitcan

bereplaced.Seegure15.

SERVICE AND ADJUSTMENTS

ENGLISH

SPROCKET

SHAFT

AGITATOR

HAIRPIN