15

24

The types of Safety Sign and locations on the equipment are shown in the illustration below. Good safety requires

that you familiarize yourself with the various Safety Signs, the type of warning and the area, or particular function

related to that area, that requires your SAFETY AWARENESS.

REMEMBER: If Safety Signs have been damaged, removed, become illegible or parts replaced without Signs, new

Safety Signs must be applied. New Safety Signs are available from your authorized distributor or factory.

SAFETY SIGN LOCATIONS

SAFETY SIGN LOCATIONS

NO. PART NO. DESCRIPTION

1 101101 Warning (540 RPM)

2 101103 Danger (Keep Away)

3 M100 (101157) Warning (Prevent Injury)

4 101100 Danger (Rotating Blades)

OWNER SERVICE

(continued)

BLADE SERVICING

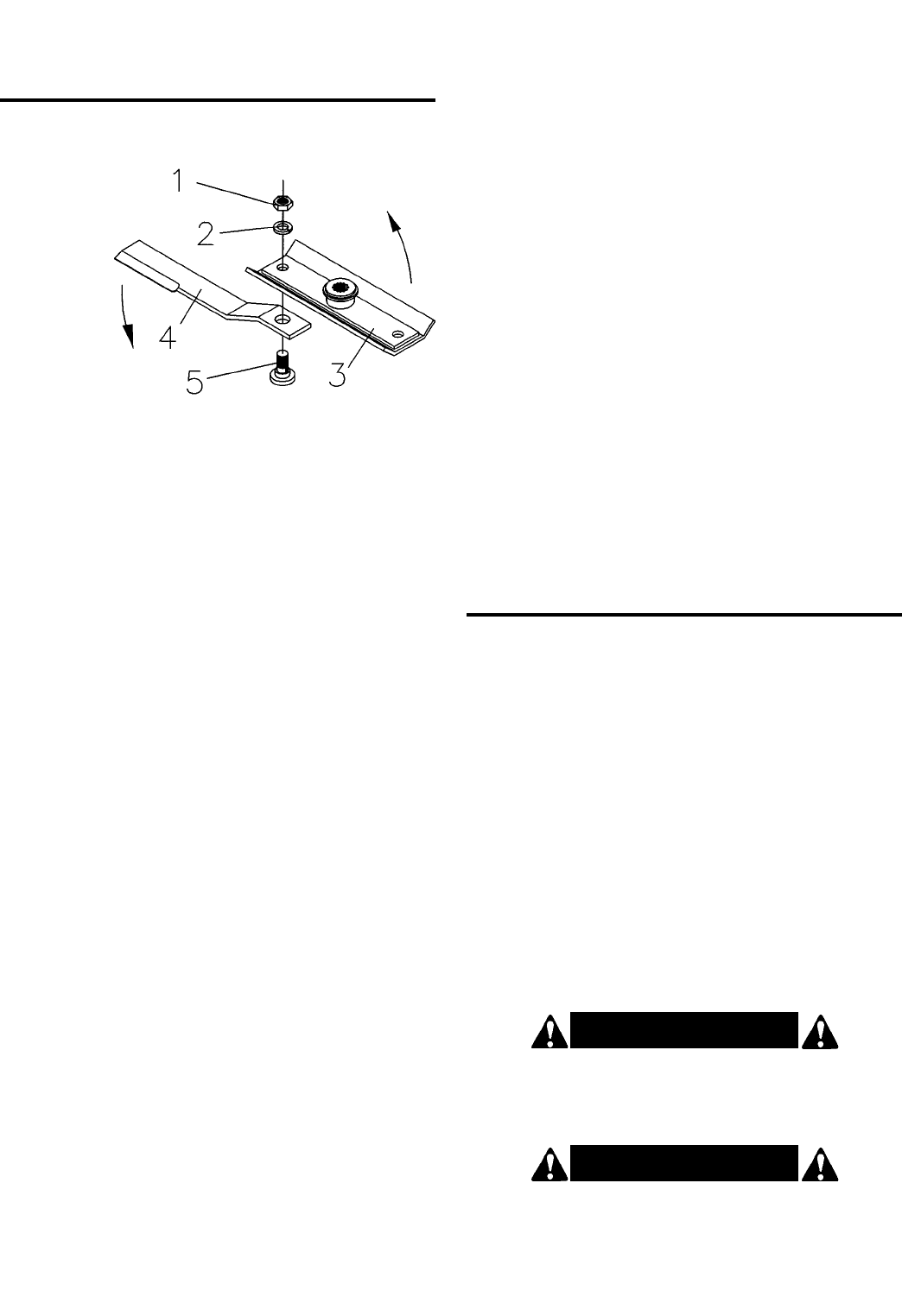

BLADE REMOVAL (Figure 7)

1. Jam nut

2. Lockwasher

3. Blade beam

4. Blade

5. Blade bolt

Figure 7. Blade Installation

SHEAR BOLT REPLACEMENT

Remove driveline shield bell. (Refer to page 19 for

instructions.)

Make sure the input shaft of the gearbox is greased.

This reduces the chance of the PTO shaft yoke from

galling to the input gearbox shaft if the shear bolt should

break.

Rotate driveline to align holes in yoke and shaft. Install

shear bolt and secure with locknut. Replace driveline

shield bell.

Disconnect driveline from tractor PTO.

It is necessary to gain access to bottom side of cutter

for blade removal. Raise cutter and block securely.

Align crossbar (3) with blade access hole in the cutter

deck. Remove nut (1) and lockwasher (2) then carefully

drive bolt (5) out of crossbar.

Insert blade bolt (5) through blade, align key on blade

bolt with keyway in blade beam and push blade bolt

through blade beam. Insert lockwasher (2) and nut (1)

through blade access hole in the cutter deck, install on

bolt (5) and tighten to 350 lbs.-ft.

Repeat for opposite blade.

Sharpen both blades at the same time to maintain bal-

ance. Follow original sharpening pattern. Do not sharpen

blade to a razor edge, but leave at least a

1

/

16

” blunt edge.

Do not sharpen back side of blade.

Rotate blade beam (3) and repeat for opposite blade.

Always replace or sharpen both blades at the same

time.

Inspect blade bolt (5) for nicks or gouges; replace if any

are found. Insert bolt through blade. Blade should swivel

on bolt. Determine cause if it does not and correct.

Align blade beam (3) with blade access hole in the cut-

ter frame. Apply a liberal coating of Never Seez

®

or

equivalent to blade bolt and blade beam hole. Make sure

blade is offset away from cutter.

Never Seez is a registered trademark of the

Never Seez Corporation.

W ARNING!

FAILURE TO USE CORRECT SIZE SHEAR BOLT

MAY CAUSE PERSONAL INJURY OR DEATH.

W ARNING!

FAILURE TO INSTALL RETAINING CLIP WILL

ALLOW DRIVELINE TO SWING FREELY IF BOLT IS

SHEARED CAUSING POSSIBLE INJURY OR DEATH.

IMPORTANT

If blade bolt (5) is seized in blade beam and extreme

force will be required to remove it, support blade

beam from below to prevent gearbox damage.

IMPORTANT

When sharpening blades, grind each blade the

same amount to maintain balance. Replace blades in

pairs. Unbalanced blades will cause excessive vibra-

tion which can damage gearbox bearings. Vibration

may also cause structural cracks to cutter.

IMPORTANT

Always use approved

1

/

2

” NC x 3” grade 2 shear bolt

as a replacement part. Using a hardened bolt or

shear pin may result in damage to driveline or

gearbox.

IMPORTANT

Blade beam rotation is counter-clockwise when

looking down on cutter. Be sure to install blade cut-

ting edge to lead in counter-clockwise rotation.

BLADE SHARPENING