1316

OPERATION INSTRUCTIONS (continued)

Never locate auger by putting hands on auger,

gearbox, or boom when there is any sign of rotation

on the driveline or auger or if the tractor is running.

WARNING!

Do not shovel dirt away from a turning auger, as the

shovel can be caught by the auger and thrown. Do

not allow anyone to stand behind or to the side of an

operating auger. ALL persons should be at least 25

feet away.

CAUTION!

Engage the tractor PTO with the engine at idle (or below

1000 engine RPM). As the auger penetrates the ground,

lower the unit slowly with the 3 pt. hydraulic system. DO

NOT LET THE AUGER SCREW ITSELF INTO THE

GROUND! Auger must dig with the dirt breaking up and

being carried to the top by the auger flighting.

Once the hole is dug to the desired depth raise the

auger while rotating to bring the dirt out of the hole.To get

a clean hole, it is sometimes best to lower the auger into

the hole with the auger turning and then, when at the bot-

tom, stop the rotation and raise the auger while not turn-

ing. This brings the dirt up with little left in the hole.

For best results, allow the digger to dig about half the

required depth, then lift it partially out of the hole to

remove dirt and then re-enter hole and finish to the

desired depth.

A Grade 2 (

5

/

16

”x 2

1

/

2

”) shear bolt is included with your

post hole digger. If the shear bolt shears, replace only

with a soft, Grade 2 shear bolt. DO NOT USE A HARD

SHEAR BOLT! Use of a hard shear bolt could result in

damage to the gearbox or other post hole digger parts

and voids any warranty.

Do not run the digger while transporting, as damage to

the PTO shaft could occur.

DO NOT LET THE DIGGER DIG SO DEEP THAT THE

PTO SHAFT IS RUNNING IN THE DIRT.

Once the auger is digging a hole, the tractor cannot be

moved. Make sure brake is set securely. If the tractor

does move while the auger is in a hole, damage to the

gearbox or auger can result (not covered by

warranty).

Cutting edges and screw type center point are replace-

able. They should be sharpened or replaced when worn.

In hard digging conditions, a fishtail type center point is

more aggressive and is recommended.

NOTE: Be sure auger is completely retracted from

the hole before attempting to move the tractor.

NOTE: If you have a rocky or large root soil condition, it

is recommended that a heavy duty auger by used.

If you encounter rocks or roots that catch the auger and

cause shear bolts to break, then remove the auger from

the hole and use a large, heavy pry bar to break up the

obstructing rock. A large root may have to be chopped to

remove.

NOTE: Please refer to the drawings (Figures B through

D) as to the proper mounting pattern for the cutting

edges. Correct mounting of the cutting edges will assure

a complete cut of earth by the auger.

Remain on the tractor seat while operating the post

hole digger. Assisting the machine by hand can

result in possible injury or death.

WARNING!

NOTE: Be careful when raising the auger as high

as your tractor’s 3 pt. hitch can go. This can put

the PTO shaft universal joints at an extreme

angle and cause damage to the PTO shaft! It is

best to raise the auger just enough to clear the

hole when the PTO is engaged.

It is recommended NOT to raise the auger while

it is running more than six (6) inches above the

ground.

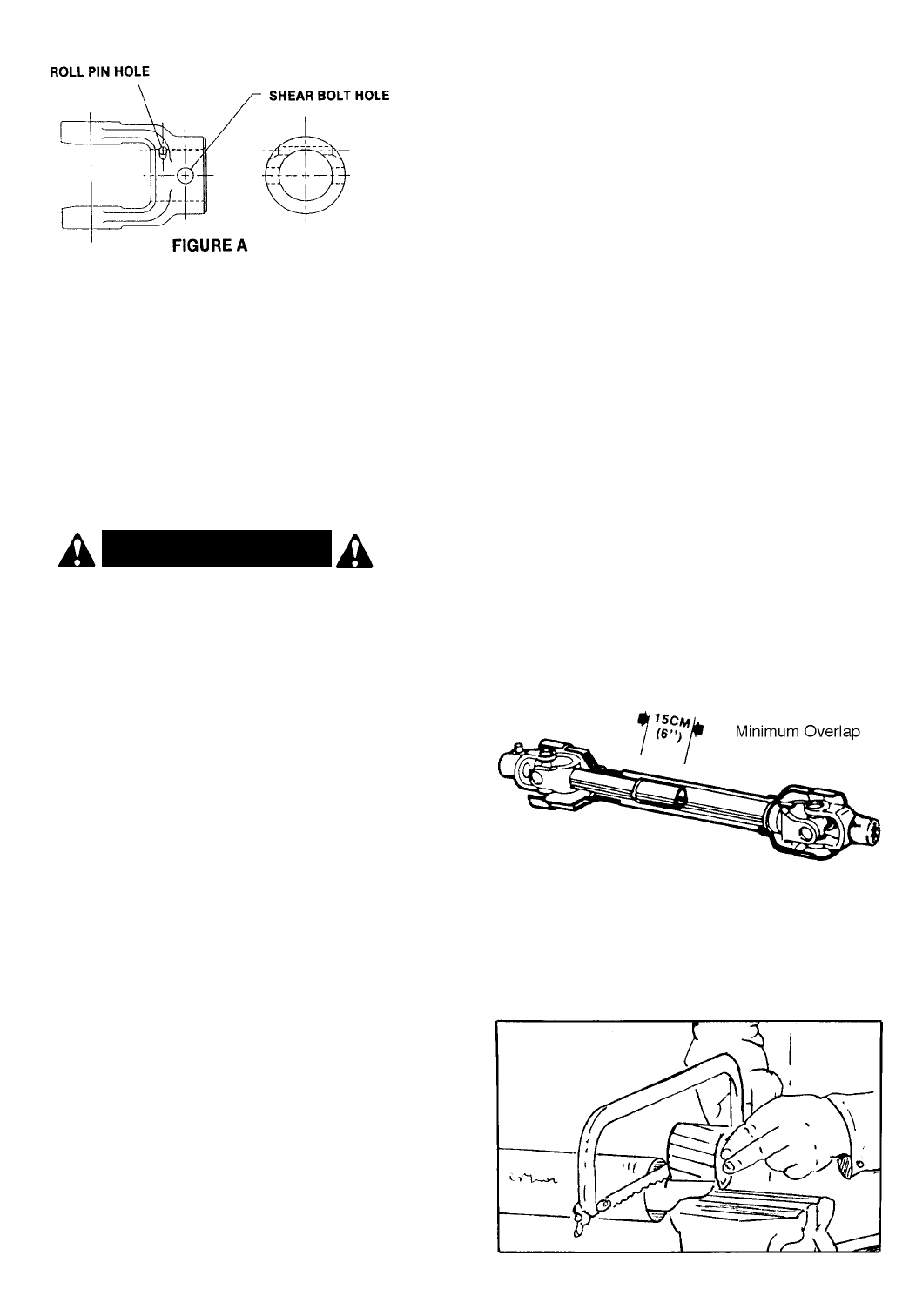

On the implement end of the PTO shaft there is a hole

in the yoke just forward of the

5

/

16

” shear bolt (see Figure

A). This hole is for the

3

/

16

” diameter x 1

1

/

4

” long roll pin

(#2504011). When this roll pin is driven in this hole, the

center of the roll pin engages into the groove on the front

of the gearbox input shaft. This prevents the PTO

assembly from coming off if the

5

/

16

” shear bolt should

shear. When replacing the shear bolt, use only a soft,

Grade 2 shear bolt. DO NOT use a hard bolt!

Attach the gearbox (Ref. #7) to the boom using the

gearbox pin (Ref. #17) and secure it with the two cotter

pins (Ref. #18). The gearbox should be placed so that

the large shaft is pointing toward the ground and the

small shaft is pointing toward the tractor.

NOTE: The gearbox is shipped WITHOUT lubricant, so

it will be necessary to fill it before use. With the gearbox

in a level position, fill to the side inspection hole with a

good 90 wt. gear lubricant. Check often and add lubricant

if necessary.

Clean tractor PTO stub shaft and the inside of the

splined driveline yoke. Pull the spring loaded ring from

the end of the yoke and slip the splined driveline yoke on

the splined PTO shaft of your tractor. Release the spring

loaded ring and push the yoke on until it locks in place.

(The spring loaded ring holds locking balls that lock the

tractor end of the PTO driveline on the tractor PTO shaft.)

Make certain the tractor PTO shield is in good condition

and securely fastened onto the tractor.

Slowly raise and lower the digger without the auger on.

Watch to see that the PTO driveline and/or shields do not

separate or get into a bind. Check to see if gearbox end

will lower to the ground. If it will not go all the way down,

then either change the hole location between the yoke

and boom or check to see if the PTO shaft is bottoming.

NOTE: If your tractor PTO shaft has a 1

1

/

8

” spline, it will

be necessary to obtain a 1

1

/

8

” to 1

3

/

8

” sleeve spline

adapter. If tractor is equipped with a 1

1

/

8

” to 1

3

/

8

” spline

adapter extension, it may be necessary to cut the PTO

shaft off in length. Check this before putting the auger on

or digging a hole. To check, raise and lower the post hole

digger with the tractor BEFORE putting the auger on.

NOTE: The use of a PTO extension could require that the

PTO driveline be shortened a considerable amount. If

this is done, the driveline halves may separate when the

post hole digger is raised to transport position.

If the PTO driveline needs to be shorter, remove the

driveline from the tractor and digger gearbox. Lower the

digger (without the auger on) until the input shaft of the

gearbox is in line with the PTO stub shaft of the tractor.

(This should be the shortest distance required for the

driveline.)

Pull the two telescoping halves of the PTO driveline

apart. Connect the tractor end to the tractor and the gear-

box end to the digger gearbox (but NOT with the two

halves together).

Hold the two driveline sections parallel to each other

and mark each end as to how much too long they are.

Then raise the digger to transport position and again

hold the two driveline halves parallel to each other and

check for a minimum of 6” (15 cm) overlap. If driveline

has less than 6” overlap, do not use. Contact your deal-

er. If at least 6” of overlap is provided, then proceed in

cutting the driveline.

Figure 1

1. If driveline must be cut to a shorter length, clamp

driveline in a well padded vise to prevent damage to

the shield. Cut off shield where marked. Using cut-off

section of shield as a guide, cut shaft the same

amount. (Figure 2)

Figure 2

INSTRUCTIONS (continued)

Do not install a longer bolt or other longer fastener!

A protruding fastener is more likely to grab loose

clothing and can cause serious injury or death.

WARNING!