6 Mount Installation

MAN0788 (1/16/2009)

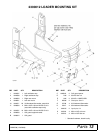

Install Optional Grill Guard

1. Attach grill guard support bracket (A) to the front

of the tractor using four cap screws (K), hardened

flat washers (G), two spacers (C) and hex nuts (L)

2. Attach grill guard (B) to support bracket (A) using

two (one per side) cap screw (E), four hardened

flat washers (H) and hex nuts (D).

NOTE: Do not overtighten cap screws (E); grill

guard must be able to pivot for access to the

battery.

3. Rotate grill guard up and secure into position

using two clevis pins (F) and lynch pins (J).

4. Torque cap screws (K) to 244 lbs-ft (330 N-m).

A. 1028909 Grill guard support bracket

B. 1028912 Grill guard

C. 1028919 Grill guard spacer

D. 230 5/8 NC Hex nut

E. 902 5/8 NC x 2 HHCS GR5

F. 26299 Clevis pin, 3/4 x 2

G. 57798 3/4 Hardened flat washer

H. 57817 5/8 Hardened flat washer

J. 304075 Lynch pin, 1/4

K. 307554 M20 x 2.5P x 60 HHCS

L. 307913 M20 x 2.5P Hex nut

Figure 4. Grill Guard Installation

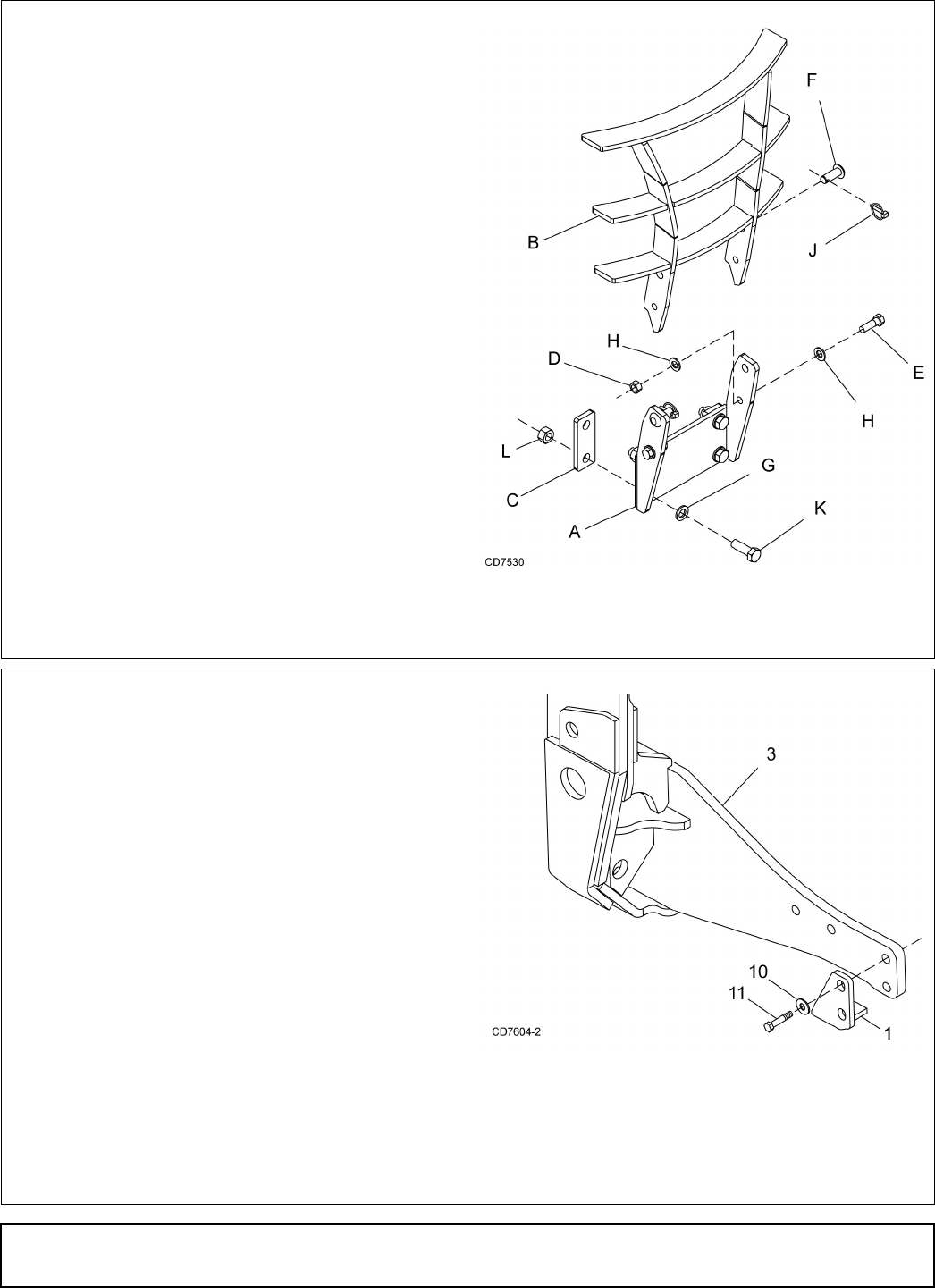

Install Oscillation Stops (Optional)

Oscillation stops are not required on all tractors. To

determine if stops are needed:

● Check tire clearance after loader has been

installed.

● Raise front tires off the ground and oscillate front

axle up and down, turning the tires in both direc-

tions.

● If tires contact loader or loader mount, oscillation

stops will be required.

1. Remove the two from cap screws on loader

mount. Place oscillation stop over mount and

secure using two cap screws (11) and hardened

flat washer previously removed.

2. Repeat steps to install oscillation stop on opposite

side of tractor.

3. Torque cap screws (11) to 374 lbs-ft (507 N-m).

1. 1026397 Left oscillation stop

2. 1026398 Right oscillation stop

Figure 5. Right Oscillation Stop Installation

10. 1006371 3/4 Hardened flat washer, extra thk

11. 1028950 M20 x 2.5P x 80 mm HHCS CL10.9

(used with oscillation stops only)