10 Operation

MAN0101 (Rev. 9/15/2006)

adjusted to deliver the desired down pressure and

roller action and achieve the desired seedbed appear-

ance.

When the situation permits, making a second pass 90-

degrees to the first is an effective way for the roller pins

to penetrate areas where uneven soil conditions exist.

In extremely compacted soil conditions, add extra

weight to the renovator to help the roller pins penetrate

the turf and soil sufficiently.

Operation

The power for operating the renovator comes from con-

tact between the renovator rollers and the turf.

Know how to stop the tractor and renovator quickly in

an emergency.

Survey the area to be worked and remove any obstruc-

tions that may affect the performance of the equipment.

Tractor Stability

A minimum 20% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, front tractor wheels could raise up result-

ing in loss of steering. The weight may be attained

with front wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and equipment.

Do not estimate.

Figure 3. Tractor Stability

Attach Super Turf Renovator to Tractor

NOTE: Super Turf Renovator is designed for use on

Category I, 3-point tractors. See page 4 for specifica-

tions.

1. Attach the tractor’s lower lift arms to the renovator

and secure with mounting pins (11) and klik pins.

See Figure 4.

Figure 4. Lift Arms Attached to Renovator

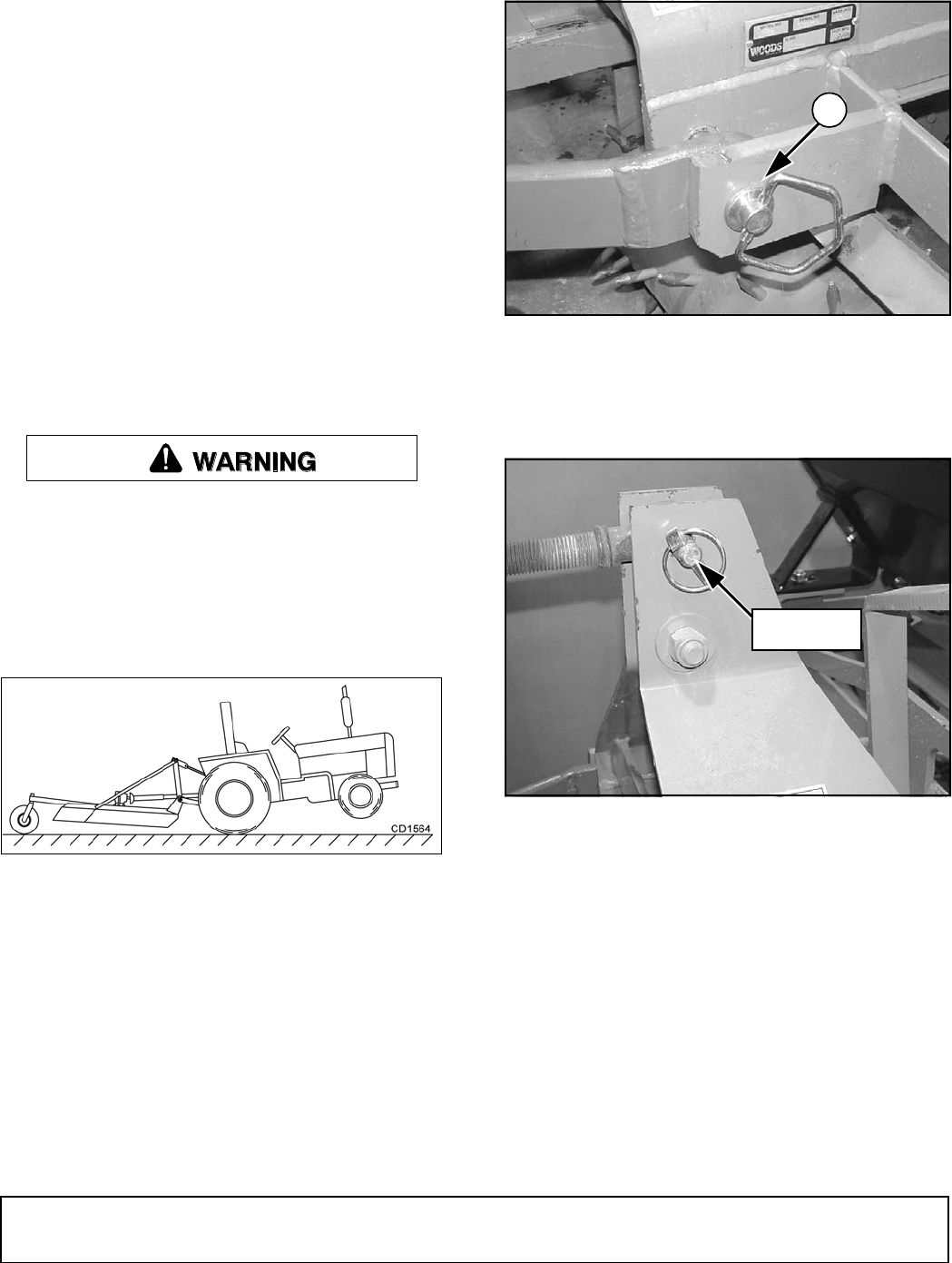

2. Attach the tractor’s top link to the upper mast of the

renovator. Secure with high-strength top link pin

and retaining pin provided with the tractor. See

Figure 5.

Figure 5. Top Link Attached to Renovator

3. Adjust top link as needed to level the renovator

forward and backwards.

4. Adjust the lower lift arm anti-sway device to

prevent the renovator from excessive side-to-side

movement.

NOTE: An optional Quick Hitch Mounting Kit is avail-

able.

11

DP1

Top Link Pin

DP2