Owner Service 25

MAN0571 (Rev. 6/15/2007)

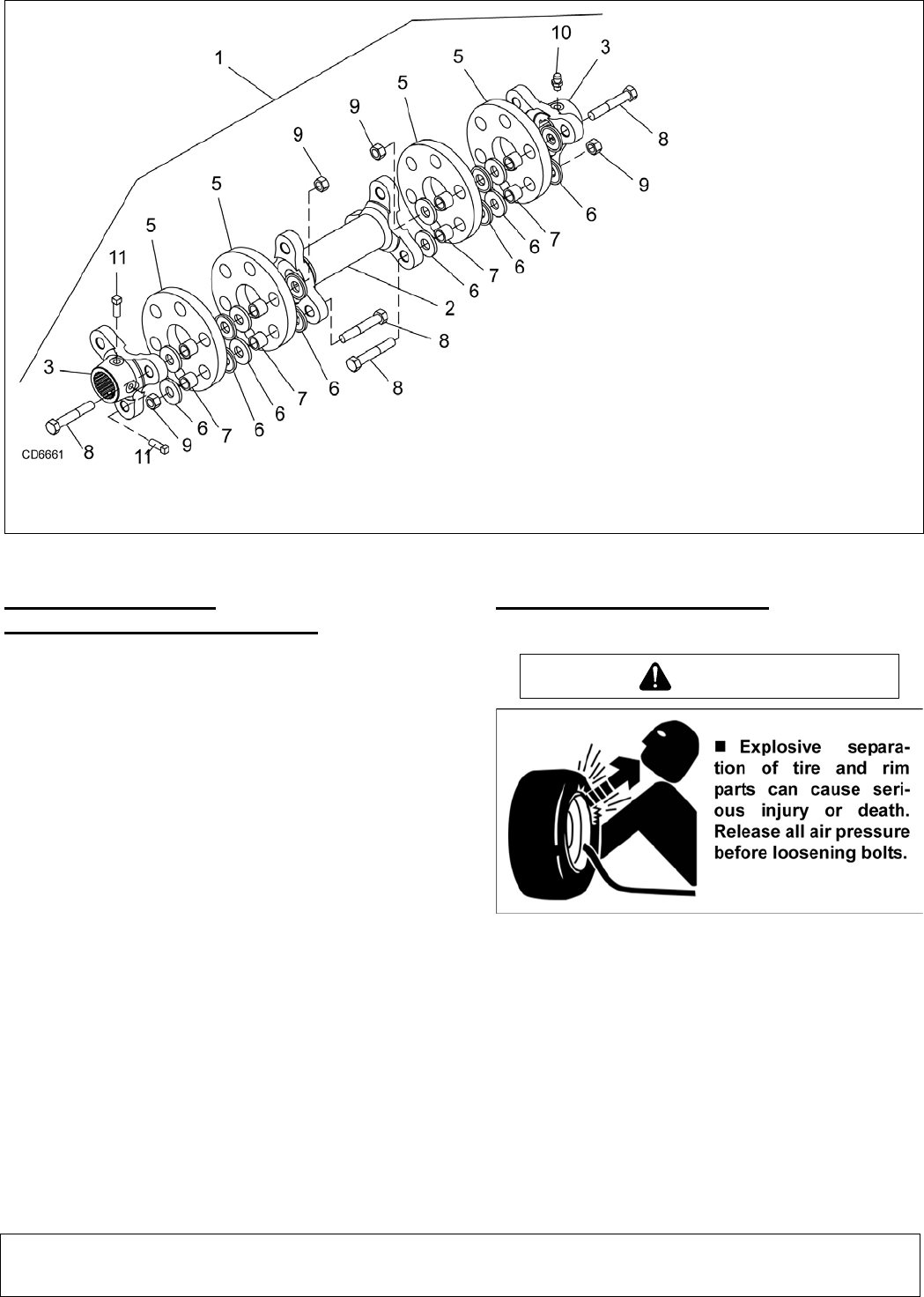

Figure 14. Flexible Coupler

FLEXIBLE COUPLER

RUBBER DISK REPLACEMENT

The flexible coupler side drive is designed to flex when

striking heavy objects or during start-up to protect gear-

boxes. The rubber disks will wear out over time and

require replacement much like slip clutch disks. To

maximize rubber disk life, lower tractor engine speed to

an idle when engaging the PTO and avoid striking the

ground with cutter blades.

Periodically inspect the disks for signs of cracking. A

disk may run for some time after a crack starts but this

is the first sign that disk replacement is required in the

future.

To replace the disks, remove hardware items 6, 7, 8,

and 9. Remove sleeves (7) from old disk and install in

new disk. Reassemble and torque bolts to 85 lbs-ft.

See Figure 14. Take special care not to rotate gearbox

shaft and throw blades out of time. If rubber disks have

failed and blades are hitting, you will need to re-time

the blades per instructions on page 35.

SERVICING TIRES SAFELY

Used Aircraft Tires (Figure 15)

Do not attempt to mount a tire unless you have the

proper equipment and experience to perform the job.

Always maintain the correct tire pressure. Do not inflate

tires above the recommended pressure. Never weld or

heat a wheel and tire assembly. The heat can cause an

increase in air pressure and result in a tire explosion.

Welding can structurally weaken or deform the wheel.

When inflating tires, use a clip-on chuck and an exten-

sion hose long enough to allow you to stand to the side

— not in front of or over the tire assembly. Use a safety

cage if available.

Check wheels for low pressure, cuts, bubbles, dam-

aged rims, or missing lug bolts and nuts.

1. Complete drive

2. Inner connector yoke

3. Outer connector yoke 1-3/4 20-spline

5. Rubber disk

6. Shaped washer

7. Bushing, .63 ID

8. Hex head cap screw

9. M16 x 2.0 Lock nut

10. Grease fitting

11. 3/8 NC x 3/4 Square head set screw

WARNING