38 Assembly

MAN0571 (Rev. 6/15/2007)

ASSEMBLY INSTRUCTIONS

DEALER SET-UP INSTRUCTIONS

These instructions are for the assembly of the DS1260

and DS1440 mounted, semi-mounted and pull-type

cutters as well as the DSO1260 semi-mounted cutter.

Many of the procedures apply to all units. When an

instruction applies to a specific unit, the section

heading will indicate which unit. Assembly of options

may not apply to all units.

Assembly of the cutter is the responsibility of the

Woods dealer. It should be delivered to the owner

completely assembled, lubricated, and adjusted for

normal cutting conditions.

The cutter is shipped partially assembled. Assembly

will be easier if aligned and loosely assembled before

tightening hardware. Recommended torque values for

hardware are located in the Bolt Torque Chart, page

82.

Select a suitable working area. A smooth hard surface,

such as concrete, will make assembly much quicker.

Open parts boxes and lay out parts and hardware to

make location easy. Refer to illustrations, accompany-

ing text, parts lists and exploded view drawings.

Complete check lists on page 52 when you have com-

pleted the assembly.

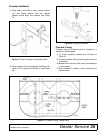

DS1260 & DS1440 PULL-TYPE CUTTER -

REAR HALF (Figure 28)

Place jackstands under cutter to raise it off the ground

to provide clearance when assembling cutter. See

“BLOCKING METHOD” on page 21 for jackstand

placement.

Install Rear Tailwheel

1. Attach tailwheel arms (1) to the tailwheel using

eight (four per arm) cap screws (21) and lock nuts

(22).

NOTE: Position tailwheel arms on tailwheel to

desired location (usually on row crop centers).

Wheel hubs should be positioned to the outside of

the cutter.

2. Attach solid or aircraft tires to wheel hubs using

five lug nuts (33). Install the chamfered side of the

lug nut toward the inside for steel rim for pneumatic

tires and rims (shown).

NOTE: Install the flat side of the nut toward the

inside for solid tires and aircraft tires.

Install Attitude Rod

Slide attitude rod (3) under right spindle driveline and

through pivot block on the tailwheel. Loosely install

washer (25) and two hex nuts (26).

Install Spring Arm

1. Attach spring arm (11) to cylinder (6) or ratchet

(10) using pin (13).

2. Place spring arm (11) and spring (12) on deck as

shown. Secure spring arm (11) to spring arm lugs

(on the cutter) using pin (14) and two cotter pins

(27). Install retaining cap screw (28) and flange

lock nut (24).

Install Height Adjustment Device

Ratchet

Attach ratchet (10) to tailwheel lugs and secure with pin

(15) and two cotter pins (27).

Cylinder

1. Place hydraulic cylinder (6) between lugs (Position

A) on tailwheel.

2. Extend cylinder rod, place transport lock bracket

(5) over cylinder rod end and between lugs on

tailwheel.

3. Align holes of cylinder rod, transport lock bracket

and lugs on tailwheel. Secure assembly using pin

(15) and two cotter pins (27).

Install Hydraulic Hose

On pull-type units with optional hydraulic cut-

ting height adjustment, use a single-acting cylinder

with a maximum extended length of 28-1/4" (718

mm) from attaching point center to center.

NOTICE

■ If using a cylinder other than the one supplied

by Woods, make sure a breather fitting is installed

in the cylinder rod end port. Use a restricter fitting

in the base end port to dampen the cutter lowering

action.

1. Install reducer bushing (7) and restricter swivel

elbow (8) in port at base end of cylinder (6).

Position elbow to point toward front of cutter.

NOTE: Make sure there is a breather fitting

installed in the rod end port.

2. Connect hose (9) to elbow (8).

3. Install optional stroke control kit (16) to cylinder

rod. Stroke control kit is used to set cut height.