Dayton Operating Instructions and Parts Manual

16

Dayton Diesel Electric Generator

®

4W315C

107358

NOTE: Much more fluid is lost during

summer than in winter.

Before starting, check for physical damage

to the battery and also the electrolyte

levels, and replenish with distilled water up

to the upper mark if necessary. When

actual damage is discovered, replace the

battery. Check battery fluid monthly.

Before charging,

remove the cap

from each cell of the battery. Charge

the battery in a place where there is

plenty of ventilation. Discontinue

charging if the electrolyte temperature

exceeds 45

°

C (117

°

F).

Do not charge the

battery with the

battery cable still connected. The diodes

will be damaged by the high voltage.

Connect the (+)

lead of the charger

to the (+) terminal of the battery, and

the (–) lead to the (–) terminal. Re-

versed polarity will damage the

charger rectifier or the battery.

element regularly.

CLEANING AND REPLACING THE FUEL

FILTER

The fuel filter also has to be cleaned

regularly to insure maximum engine output.

Clean fuel filter every six months or 500

hours of operation. Replace fuel filter every

year or 1000 hours of operation.

1. Drain the fuel oil from the fuel tank.

2. Loosen the nuts of the fuel cock and

pull out the filter from the fuel tank

filler port. Wash the filter thoroughly

with diesel fuel.

A clogged spark

arrester hinders

the flow of exhaust gas. This reduces

engine output, increases fuel con-

sumption and makes starting difficult.

Make sure you clean your spark

arrester regularly.

TIGHTEN CYLINDER HEAD BOLTS

Tightening the cylinder head bolts requires

a special tool. Don’t try it yourself. Consult

your Yanmar dealer.

CHECKING THE INJECTION NOZZLE,

INJECTION PUMP, ETC.

• Adjusting the valve head clearance for

the intake and exhaust valves.

• Lapping of intake and exhaust valves.

• Replacing piston ring.

All these require special tools and skills.

Consult your Yanmar dealer.

Do not perform the

injection nozzle

test near an open fire or any other kind

of fire. The fuel spray may ignite. Do

not expose bare skin to the fuel spray.

The fuel may penetrate the skin and

cause injury to the body. Always keep

your body away from the nozzle.

CHECKING AND REPLENISHING BATTERY

FLUID AND CHARGING THE BATTERY

Battery fluid will be lost through continu-

ous charging and discharging.

The battery

electrolyte

contains sulfuric acid. Protect your

eyes, skin, and clothing. In case of

contact, flush thoroughly with water

and get prompt medical attention,

especially if your eyes are affected.

Batteries generate

hydrogen gas,

which can be highly explosive. Do not

smoke or allow flames or sparks near

the battery, especially during charging.

CLEANING THE SPARK ARRESTER

If the engine has

been running, the

muffler and the spark arrester will be

very hot. Allow these to cool before

proceeding.

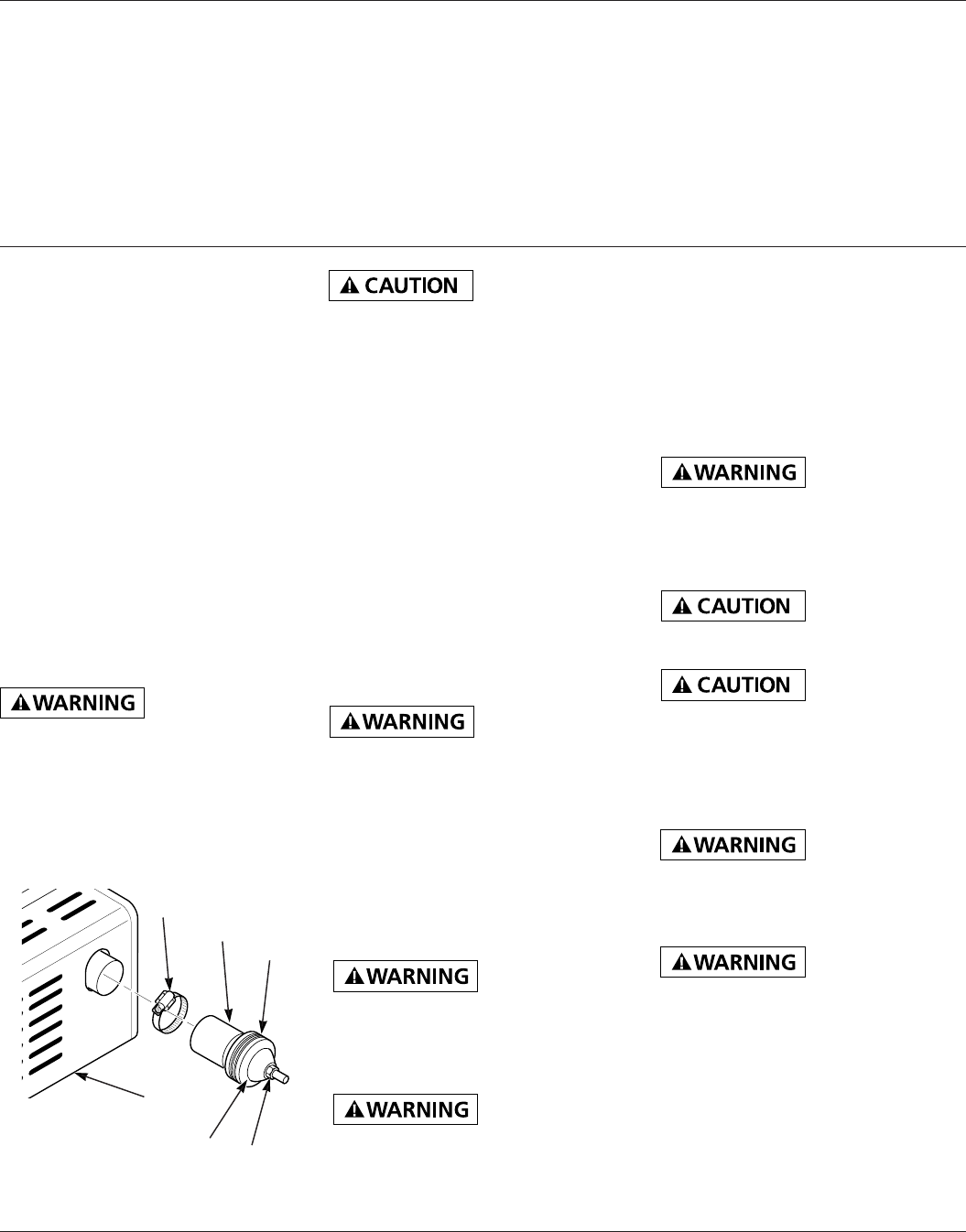

Remove the lock nut, end cap and diffuser

discs and clean off the carbon deposits.

Clean spark arrester every three months or

100 hours of operation (or earlier if dirty).

Clamp

Spark

Arrester

Diffuser

Discs

Muffler

End Cap

Lock Nut

Figure 25 - Spark Arrester

Maintenance and Repairs

(Continued)

Storage

Remove all fuel

from fuel tank

before storing generator. Store fuel in

approved container. Store fuel in a

well-vented area free of open flames

or sparks.

The muffler

becomes very hot

during operation. The muffler remains

hot for a while after shutdown. Let

engine cool before storing.

IMPORTANT: Keep generator level while

in storage. Never store generator upside

down or standing on end.

Cover and store generator in a clean, dry

place. Do not expose generator to extreme

high or low temperatures during storage.