22 unigreen

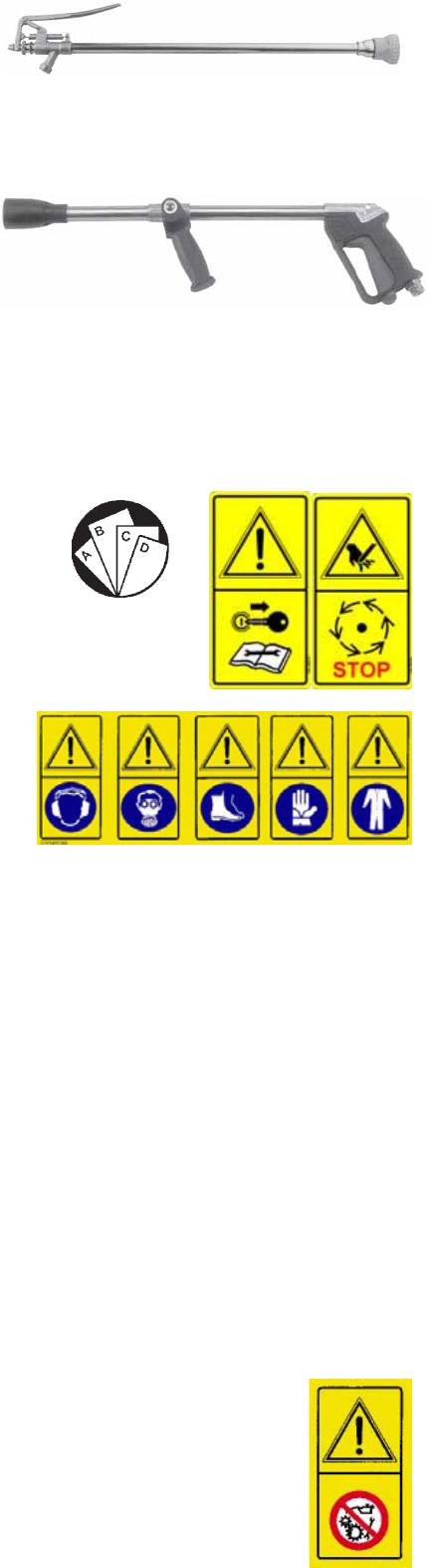

7 HAND LANCES

When using hand lances bear in mind the following notes:

= Don’t direct the jet of liquid towards electric power lines or zones where

there is electrical current, houses or where people might pass.

= Don’t point the jet at people or animals.

The jet can cause serious injuries simply due to the mechanical force of the

liquid under pressure.

= Never block the spraying lever of the lance in an open position because if

the lance falls it will be uncontrollable.

= At the end of work after you have stopped the pump, make sure that any

residual pressure in the pipes under pressure has been drained to avoid

unexpected jets when putting the lance away. There are various types of

lances; with a lever, mitra spray gun and pistol grip.

For further information please refer to the handbook in the package.

The lever lance is controlled by opening lever A which, depending on how much

it’s pressed, produces a conical spray or direct jet. The standard nozzle is Ø 1.5

The mitra spray gun can produce a direct jet or a conical spray and the type of

spray is selected by pushing lever B forwards or backwards. Use lever C to

open the jet. The standard nozzle is Ø 2.5

Replacement nozzles are available for all of the lances and the capacities are

indicated in the tables TAB.4 and TAB.5 ( page 29).

8 MAINTENANCE

All of the maintenance operations and repairs must be carried out with the

machine and cardan shaft stopped and the tank and circuit clean of any

residues of chemical products.

The maintenance of the mistblower is essential for maintaining a high level of

safety. Also consult the single handbooks of the main components of the

mistblower.

WARNING: the indications to follow for using chemical products are indicated in

paragraph 2.2.1.

8.1 PROGRAMMED MAINTENANCE

(TAB. N° 7, page 30)

We recommend using a table of programmed maintenance to follow in time to

keep the mistblower in an efficient working condition.

For major and important maintenance jobs we recommend using the normal

UNIGREEN assistance service available from your reseller, (if necessary)

replacing parts using original spare parts only.

8.2 ROUTINE MAINTENANCE

= After every treatment wash the inside of the tank and the entire circuit as

indicated in paragraph 4.13

= Periodically check that the suction and delivery filters are clean

= Check the oil level in the volumetric compensator of the pump

= The use of chemical products that are particularly damaging for a nitrile

rubber mix can cause the diaphragm to break before time.

In these conditions check the state of the components more often. There are

diaphragms made of special materials (viton and desmopan) that are available

on request.

= When doing treatments with copper hydroxide you should take great care

to thoroughly clean the system, washing it after each treatment because

hydroxides attack parts that aren’t painted or protected by hot galvanising.

To prevent chemical attacks we recommend spraying transparent paint on the

parts that are most exposed to the product and equipping the mistblower with

stainless steel pressure gauges.

8.2.1 CLEANING THE NOZZLES

Check the state of wear of the nozzles and replace them when the delivery is

over 30-35% of the theoretical level.

If you notice even a partial blockage of a nozzle proceed as follows:

- drain the pressure and stop the machine

- dismantle the screw or bayonet ringnuts holding the nozzles

- clean with a small brush or compressed air, don’t use nails, punches or

bradawls

- reassemble the nozzles and the ringnuts, replacing the filters and seals.

8.2.2 LUBRICATION

The moving mechanical components must be lubricated to prevent wear and

overheating. This lubrication can be done with grease or oil: oil allows

C

B

A

FIG. 22