20 unigreen

6 SPRAYING

WARNING: the indications to follow when using chemical products are

indicated in paragraph 2.2.1.

6.1 DESCRIPTION OF THE DIFFUSERS

The distributor accessories of the AIRDROP range are equipped with

variable diffusers (FIG. 18) that let you direct the airflow (and as a

consequence the treatment) on the vegetation to treat, adapting to your

various needs.

According to the configuration of the accessory the diffusers have outlet

mouths with different shapes and sections, furthermore they are equipped

with a tap for turning the liquid on/off (R) so you can independently close one

or more diffusers in the case of scarce vegetation.

In the VENTAGLI version the diffuser is the fan itself.

6.1.1 NON-DRIP VALVE

There is a non-drip valve (V) on the distributors (FIG. 18) that limits and/stops

the mix dripping when the supply tap is closed. In any case we recommend

closing the delivery of the mix a few seconds before disconnecting the power

takeoff.

In versions with fans the valve is mounted immediately upstream of the dosing

taps (see paragraph 6.4.1)

6.2 DESCRIPTION OF THE MFC

®

NOZZLES

The Unigreen low-volume pneumatic atomization system uses MFC

®

nozzles (FIG. 19) consisting of a steel wire supported by Nylon deflector

vanes that also act as collectors for the liquid. The high-speed action of the

air atomises the film of liquid on the wire; in this there is a high air/water

surface area in contact and not just a single atomisation point, which means

a big advantage in terms of uniformity and homogeneity of the jet.

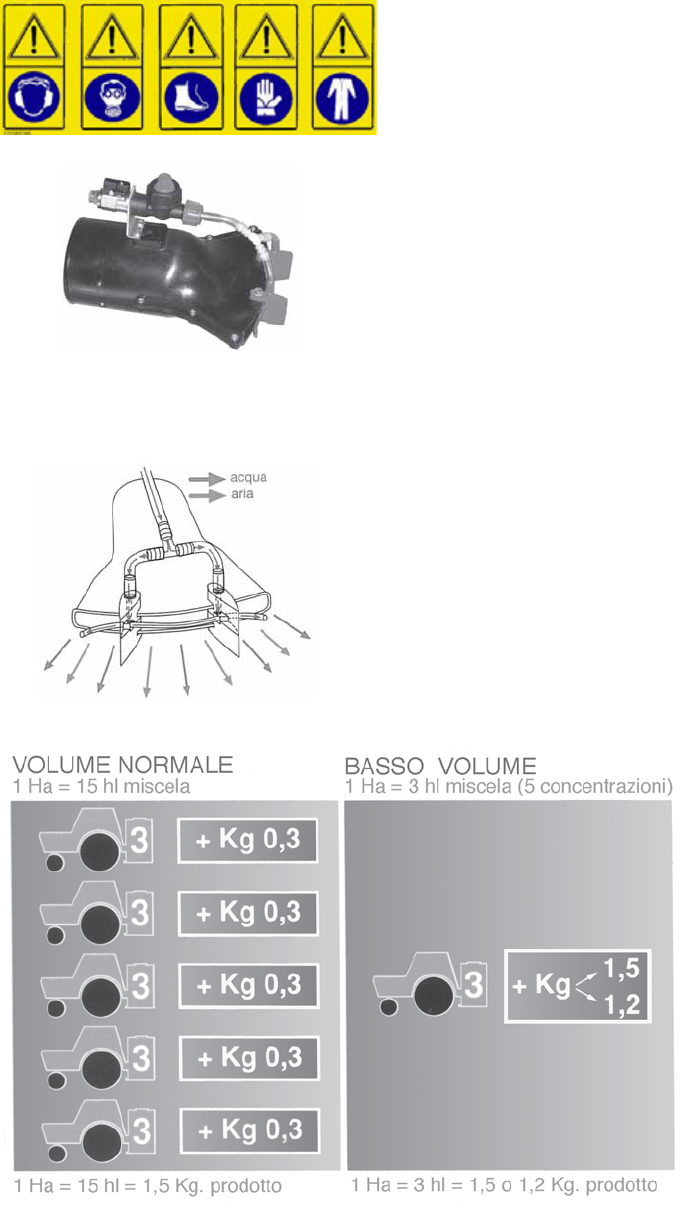

6.3 MIXTURE CONCENTRATION

As you may know, the pneumatic equipment are

used for more or less concentrated treatments.

To prepare the mixture, it is necessary to follow

the instructions on the chemical product label. As

a general rule, the product quantity to be sprayed

on the hectare is the same as normal-volume

treatments (a 20%-reduction is also possible);

the water volume is reduced a lot even up to 9

times = 10 concentrations.

We will try to clear this concept as regards

concentration with an example for the correct

use both of equipment and products.

Imagine that in order to protect a normal-volume

culture hectare you use 15 ml. of mixture. If the

product dose recommended by the expert

amounts to 100 g/hl. (normal-volume dose

indicated on the label which is always to be

followed), for 15 hl. You will use 1,5 kg. of prod-

ucts. If you decide to reduce the water quantity

per hectare at 500-300-150 litres (that is to say

concentrating 3-5-10 times), in these new water

volumes we must always use 1,5 kg. of product and 1,2 kg. if necessary (for

reductions up to 20%). As a consequence, the mixture concentration can

vary according to the water quantity that you wish to use.

From this example, you can notice a reduction of 4 fillings and 12 ml. of

water.

5 MISTBLOWER CALIBRATION

The tables on pages 25 to 28 make it possible to determine the delivery in

litres/hectares of the various equipment having the following initial data:

- position of the batching tap levers (Ventagli - Fans)

- calibrated plate CP (all others diffusors)

- used pressure;

- working speed (in km/h);

- working length (in meters).

FIG. 18

V

R

FIG. 19