24

25

8. DISMANTLING AND DISPOSAL

Only trained personnel are allowed to dismantle the appliance in accordance with the current

regulations in the country where it is installed.

CAUTION

• Before disposing of the appliance, make sure it is no longer possible to operate it, by cutting

the power supply cable for example. Make sure all its parts are now inoffensive, as they

could prove to dangerous to children playing.

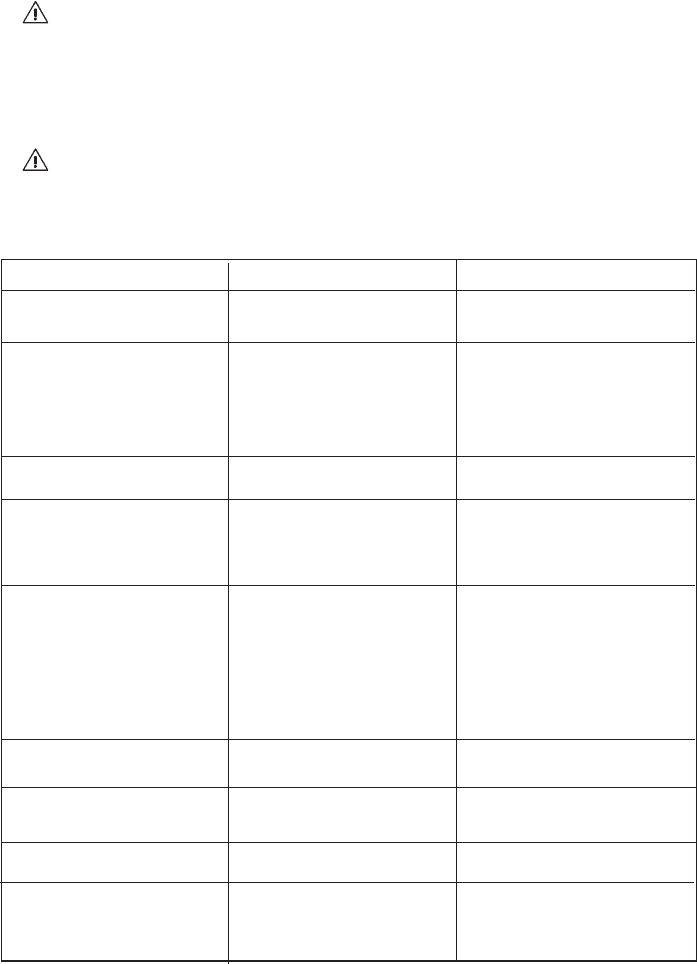

9. PROBLEMS, CAUSES AND SOLUTIONS

CAUTION

• Before taking any steps, follow the instructions in the “Switching off” section. If it is not

possible to restore correct operation of the appliance using the information in the table

below, contact a Skilled Technician.

PROBLEM

The

combustion engine does not start

or does not work properly during

operation.

When the switch is pressed, the

electric motor does not start or stops

during use.

If switch is turned, the electric

motorhums but does not start up.

The pump does not prime.

The pump does not reach maximum

pressure.

Pressure and flow are irregular

(buttons).

Excessive vibration in delivery circuit.

Excessive noise associated with

drop

in the oil level.

Excessive consumption of oil and/or

oil is whitish colour (presence of

waterin oil)

CAUSE

Refer to the operating

andmaintenance instructions for

thecombustion engine.

A safety device has cut in on the

system where the appliance is

connected (fuse, differential circuit

breaker, etc).

The plug on the power cord is

notinserted correctly.

The electrical system and / or

extension cord are not suitable.

Air intake.

Adjustment valve positioned

underpressure.

The pressure adjustment knob (29)

isnot screwed down sufficiently.

The lever (30) is in BY-PASS

position.

Bottlenecks in intake circuit.

The nozzle is worn or is too big.

Air intake

Pressure accumulator not correctly

inflated.

Bottlenecks in intake circuit.

Rupture of one or more diaphragms.

SOLUTION

Refer to the operating and

maintenance instructions for the

combustion engine.

Reset the protection device.If it cuts in

again, do not use the appliance and

contact a Skilled Technician.

Take the plug out of the socket

andinsert it correctly.

Follow instructions in the “Controls and

connection to mains electricity”section.

Check the intake circuit is intact.

Set pressure to zero with the knob (29)

(MC 16 only) or by putting thepump in

bypass with the lever (30).

Turn

the knob clockwise until

therequired pressure is reached.

Put the lever (30) in PRESS position.

Check the intake circuit (above all ifthe

intake filter is clean).

Replace the nozzle (refer toinstructions

in the “Spraying” section).

Check the intake circuit is intact.

Restore correct inflation (refer

toinstructions in the “Preliminary

procedures” section).

Check intake circuit (above all if

theintake filter is clean).

Refer to instructions in the“Diaphragm

Rupture” section.