22

23

diaphragm rupture, we recommend you drain the pump crankcase of the mixed oil and

pumped liquid and then ll it with oil or diesel to prevent the formation of rust.

• The following are frequently the causes of diaphragm rupture:

- bottlenecks in the intake circuit (inadequate hose section, very dirty lter, very dense

liquid being pumped, etc)

- the use of very aggressive chemicals

6.3 SPECIAL MAINTENANCE

CAUTION

• Only Skilled Technicians are authorised to carry out special maintenance.

• Dispose of waste oil correctly; do not dump it in the environment

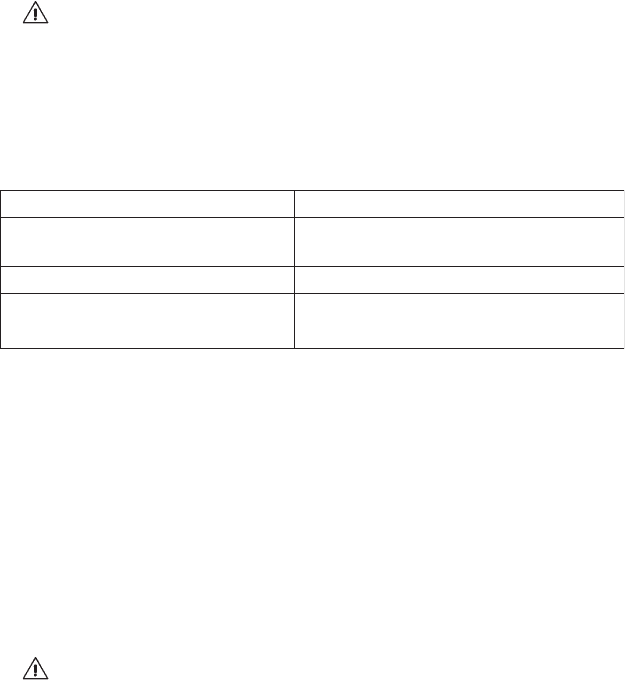

Follow the instructions in the table below for special maintenance.

For appliances tted with a combustion engine, remember to follow the instructions for special

maintenance in the engine’s operating and maintenance instructions

(*) Check more frequently if liquids are used with suspended abrasive particles.

(**) Oil must also be changed when diaphragms are replaced.

(***) Not necessary for MC16; for MC 20/20 and MC25, change when pump oil is changed

(****) We recommend replacing diaphragms regardless of their condition if particularly

aggressive chemicals are used

WARNING

• The data in the table is approximate. Maintenance may be required more frequently in cause

of particularly heavy use.

7. MOVING AND TRANSPORTATION

CAUTION

• Follow the instructions in the “Switching off” section before moving or transporting the

appliance.

• When the appliance has to be transported, remember to anchor it rmly to the means of

transport (using cables or other systems, as appropriate) and to empty the tank.

• Hold the handle (7) rmly to avoid losing your grip if knocks and bumps are caused by

uneven ground. It is important to bear this in mind if the tank is full and the ground is wet.

• Only move the appliance by means of the grips on the handle (7).

• Do not move the appliance if it is on a slope in excess of 2% or if the ground is very wet.

Every 300 hours Check the intake, delivery and adjustment valves (*)

Change the oil (**)

Every 500 hours

At the end of every season or once a year

INTERVAL FOR MAINTENANCE

ACTION

Change the reducer oil (***)

Check diaphragms and replace if necessary (****)

Check the motor-driven pump screws are tight