8

3.3 STANDARDS OF REFERENCE:

- MACHINES DIRECTIVE 98/37/CEE (Ex. Dir.89/392 CE).

- Directive 86/188/CEE: risks deriving from exposure to noise (implemented in

Italy by Legislative Decree D.L 277/1991)

- DPR 547/1955: Regulations for the prevention of accidents and hygiene at work.

- Legislative Decree D.Lgs. n°292 of the 4th of September 2002 concerning

the environmental acoustic emission of machines and equipment for use

outdoors.

-UNI EN 292-1/Nov.1992: Machinery safety – Terminology, basic methodology

-UNI EN 292-2/Nov.1992: Machinery safety - Specifications and technical

principles.

-UNI EN 294/July 1993: Machinery safety, safe distances to avoid reaching

hazardous areas with upper limbs.

-UNI EN 349/June 1994: Machinery safety, minimum spaces to prevent

crushing of body parts

-UNI EN 907/Nov.1998: Agricultural and forestry machinery - Sprayers and

spreaders of liquid fertilizers - Safety.

-EN 954-1/Dec. 1992: Safety of machinery: Basic concepts, general principles

for design.

-UNI EN 982/July 1997: Machinery safety. Safety requisites relevant to

systems and their components for hydraulic and pneumatic transmissions.

Hydraulics.

-UNI EN 1553 Agricultural machinery - self-propelled, tractor mounted, half-

trailed and towed machines. Common safety requisites

-ISO 11684/1995: Pictograms - general principles.

4 USER’S INSTRUCTIONS

4.1 TRANSPORTING AND MOVING THE MACHINE

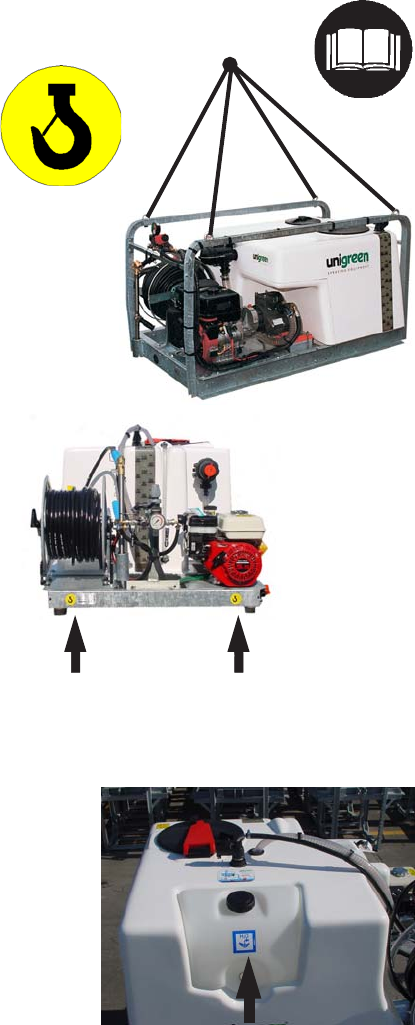

If the machine has to be lifted, use suitable slinging and tackle, crane or

bridge crane, with capacity suitable for the use. The dry weight of the machine

at the maximum level of fitting and with all the accessories allowed is

stamped on the nameplate; use slings and lifting gear with a adequate load-

bearing capacity.

Don’t stand the sprayer on soft ground or steep slopes.

Never lift or move the sprayers by hand if there is liquid in the tank. The

machine will weigh more and the movement of the liquid can change the

centre of gravity causing uncontrolled movements.

It is opportune to apply the slinging as in FIG.2 for the MASTER 55 model or

those equipped with eyebolts. It is necessary to use forklift trucks or transpallets

with an adequate capacity for other models. The forks should be placed as

indicated in the specific pictograms.

Don’t pass or stand under the machine when it is being lifted.

4.2 DESCRIPTION OF THE MACHINE

The UMP and MASTER machines are made to be mounted on the floor of the

pickup vehicle. Some models can be equipped with wheels and handlebar for

towing by hand or by small tractors.

The frame is in hot galvanised steel, the cisterns are in easy-to-empty organic

glass reinforced with glass fibre. Versions are available with the cistern in

galvanised or stainless steel.

The pumps are generally membrane and in some cases piston and are coaxially

mounted with an electric or internal combustion engine reducer.

They are equipped with an external suction filter that allows easy inspection.

All the machines are equipped with a hose nozzle for watering and/or washing

with a length of tubing.

4.2.1 HAND WASHING TANKS

The sprayers are supplied with an auxiliary hand-washing tank with clean

water and a hand tap.

This tank must always be supplied with water and the inside must be clean so

you can wash any parts of the body that come into contact with the chemical

product used.

Never drink the liquid inside.

FIG. 2

This symbol

identifies the

coupling points

of the machine