11

NOTE: In some cases due to operating conditions

(altitude, temperature etc.) your chain saw may

need a slight adjustment to the idle speed. If unit

does not Idle after restarting 2 times, follow these

steps to adjust idle.

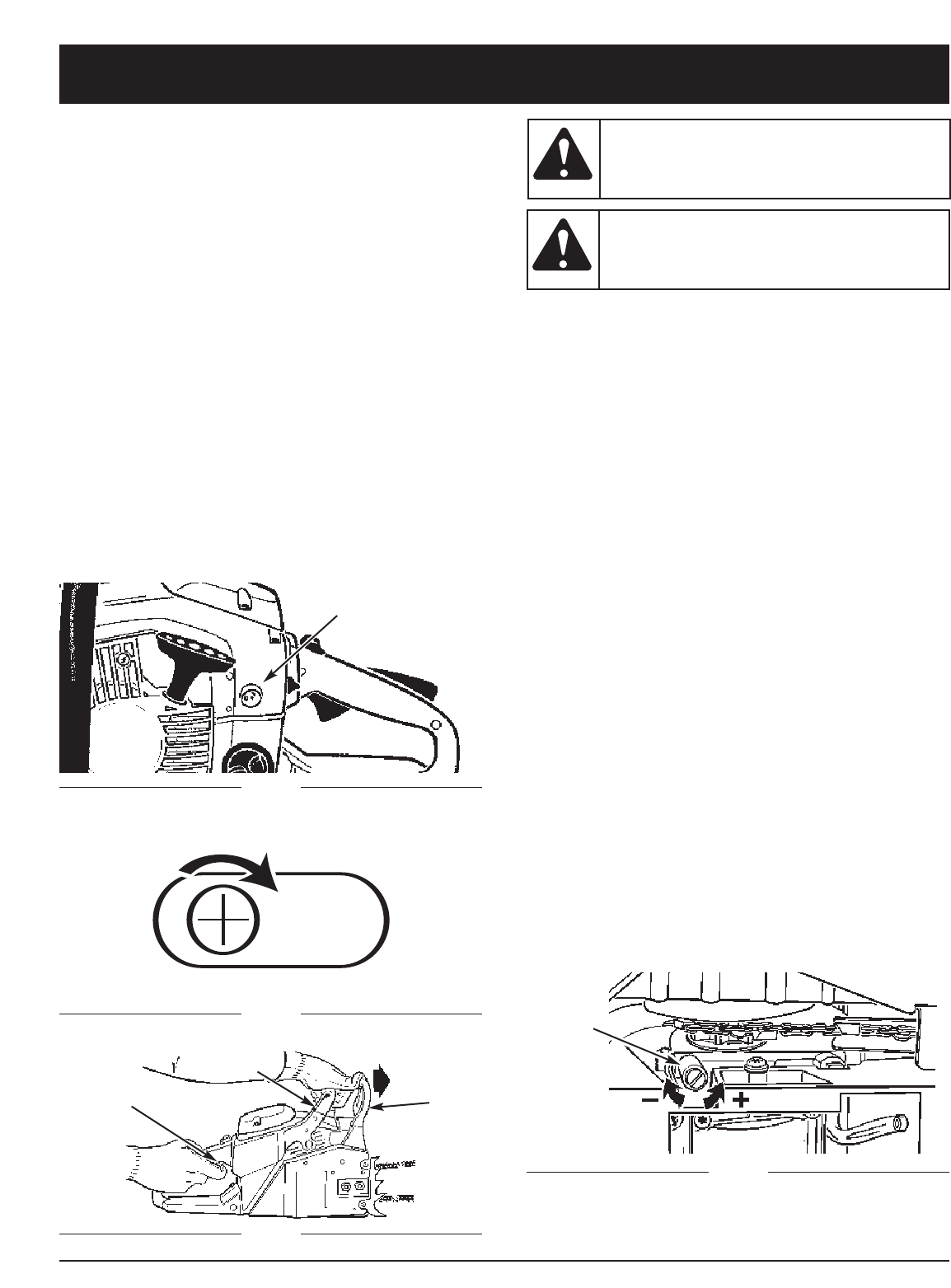

1. Idle adjustment access (L) - the symbol "T" (for

throttle) is below the adjustment hole (Fig. 8).

2. Using a Phillips or slotted screwdriver - turn screw

1/4 to 1/2 turn clockwise (to the right). Unit should

then idle properly (Fig. 9).

NOTE: If chain turns while idling - turn screw back to the

left until chain stops and unit continues to idle.

NOTE: When starting a warm engine, go back to Step 3.

Follow the steps until Step 8. Then, move the

lever to Position 3 and release the throttle trigger.

STOPPING INSTRUCTIONS

1.

Release the trigger and allow the engine to return to

the idle speed.

2. Move the STOP switch to the STOP position.

NOTE: For emergency stopping, simply activate the

Chain Brake® and move the STOP switch down.

Fig. 8

Fig. 9

L

Activate the CHAIN

BRAKE® slowly and

deliberately. Keep the chain from touching

anything; don’t let the saw tip forward.

WARNING:

If chain does not

stop, turn engine off

and take your unit to the nearest Authorized

Service Center for service.

WARNING:

Fig. 10

Fig. 11

A

C

B

D

OTHER INSTRUCTIONS

Chain Brake® Test

1. Place saw on a clear, firm, flat surface.

2.

Start engine.

3. Grasp the rear handle (A) with your right hand (Fig. 10).

4. With your left hand, hold the front handle (B) [not

Chain Brake®

lever (C)] firmly (Fig. 10).

5. Squeeze the throttle trigger to 1/3 throttle, then imm-

ediately activate the Chain Brake® lever (C) (Fig. 10).

6. Chain should stop abruptly. When it does,

immediately release the throttle/trigger.

7. If Chain Brake® functions properly, turn the engine

off and return the Chain Brake® to the DISENGAGED

position.

Chain Lubrication

Adequate lubrication of the saw chain is essential at all

times to minimize friction with the guide bar. Never starve

the bar and chain of oil. Running the saw with too little oil

will decrease cutting efficiency, shorten saw chain life,

cause rapid dulling of chain, and cause excessive wear

of bar from overheating. Too little oil is evidenced by

smoke, bar discoloration or pitch build-up.

Automatic Oiler

Your chain saw is equipped with an automatic gear driven

oiler system. The oiler automatically delivers the proper

amount of oil to the bar and chain. As the engine speed

increases, so does the oil flow to the bar pad. The amount

of oil flowing to the bar and chain may be changed by

turning the adjustment screw (D) as shown in Fig. 11.

Turn the screw clockwise to DECREASE oil flow and

counterclockwise to INCREASE the flow.

STARTING/STOPPING INSTRUCTIONS