14

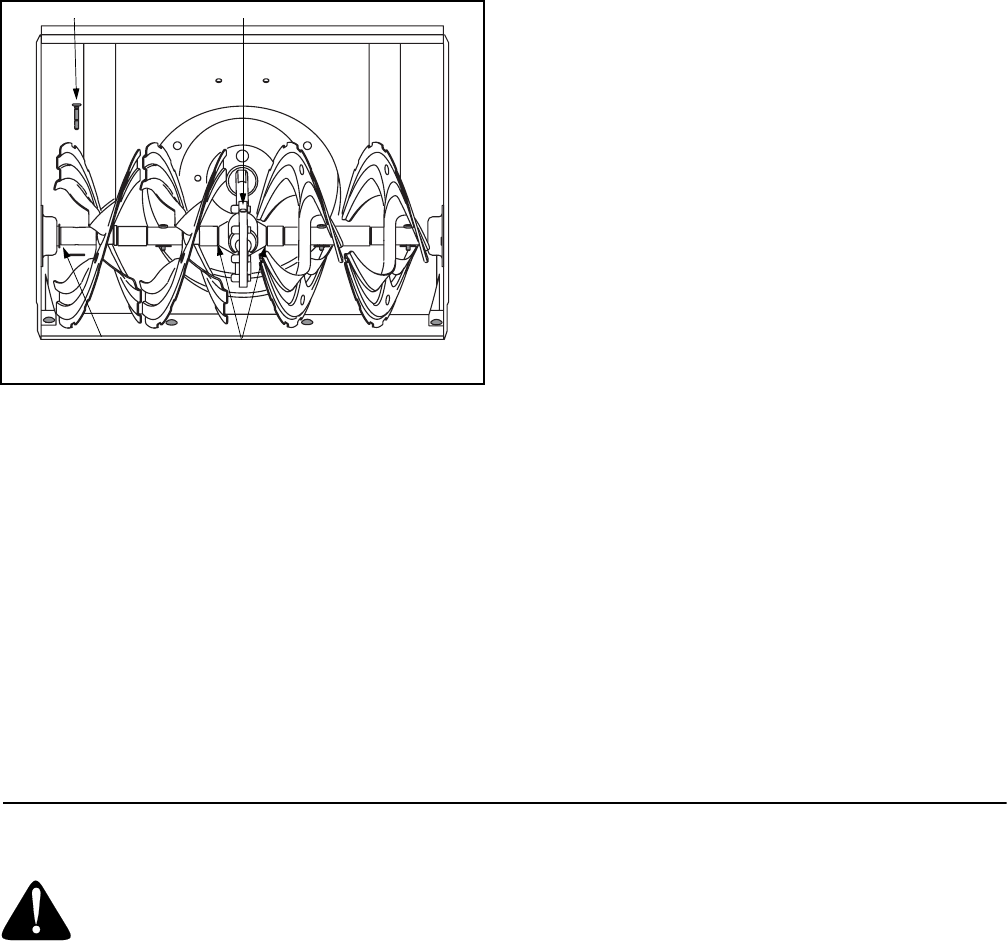

Figure 15

To check the level of grease in the gear case, remove

the vent plug. If your unit is equipped with a grease

fitting, you may, if necessary, add grease using a

grease gun and the grease fitting on the side of the gear

case.

IMPORTANT:

Do not overfill the gear case, since

damage to the seals could result. Be sure the vent plug

is free of grease in order to relieve pressure.

Auger Shaft

• At least once a season, remove the shear pins from

the auger shaft and spray lubricant inside the shaft.

See Figure 15.

• On certain models, grease fittings can be found at

either end of the auger shaft. Lubricate with a

grease gun once a season.

Auger Bearings

Every season lubricate the auger bearings and the

bearings on the side of the frame with light oil. See

Figure 15.

Drive and Shifting Mechanism

Lubricate at least once a season or after every 25 hours

of operation. Remove the rear cover, lubricate any

chains, sprockets, gears, bearings, shafts, and shifting

mechanism at least once a season. Use engine oil or a

spray lubricant. Avoid getting oil on the friction

wheel rubber and aluminum drive plate. Refer to

Figure 11.

There is a grease fitting on the top of the axle shaft

which drives the rear track drive wheels on both sides

of the unit. Grease these fittings every 25 hours or once

a season.

Gear Shaft

Lubricate the gear shaft with 6-n-1 grease at least once

a season or after every 25 hours of operation (available

at automotive stores, or order part number 737-0170).

Refer to Figure 11.

IMPORTANT:

Keep all grease and oil off of the rubber

friction wheel and aluminum drive plate.

Chute Directional Control

The worm gear on the chute directional control should

be greased with multipurpose automotive grease.

SECTION 7: SERVICING YOUR SNOW THROWER

WARNING: Before servicing, repairing, or

inspecting, disengage all controls and stop

engine. Wait until all moving parts have come

to a complete stop. Disconnect spark plug

wire and ground it against the engine to

prevent unintended starting. Always wear

safety glasses during operation or while

performing any adjustments or repairs.

Augers

• The augers are secured to the spiral shaft with

shear pins and bow tie cotter pins. If you hit a hard

foreign object or ice jam, the snow thrower is

designed so that the pins may shear. Refer to

Figure 17.

• If the augers will not turn, check to see if the pins

have sheared. Replacement shear pins and cotter

pins have been provided with the snow thrower.

When replacing pins, spray an oil lubricant into

shaft before inserting new pins.

IMPORTANT:

NEVER replace the auger shear pins with

standard pins. Any damage to the auger gearbox or

other components as a result of doing so will NOT be

covered by your snow thrower’s warranty.

Shave Plate and Skid Shoes

• The shave plate and skid shoes on the bottom of

the snow thrower are subject to wear. They should

be checked periodically and replaced when

necessary.

Vent Plug

Plastic

Bearing

Shear Pin

Bearings