8

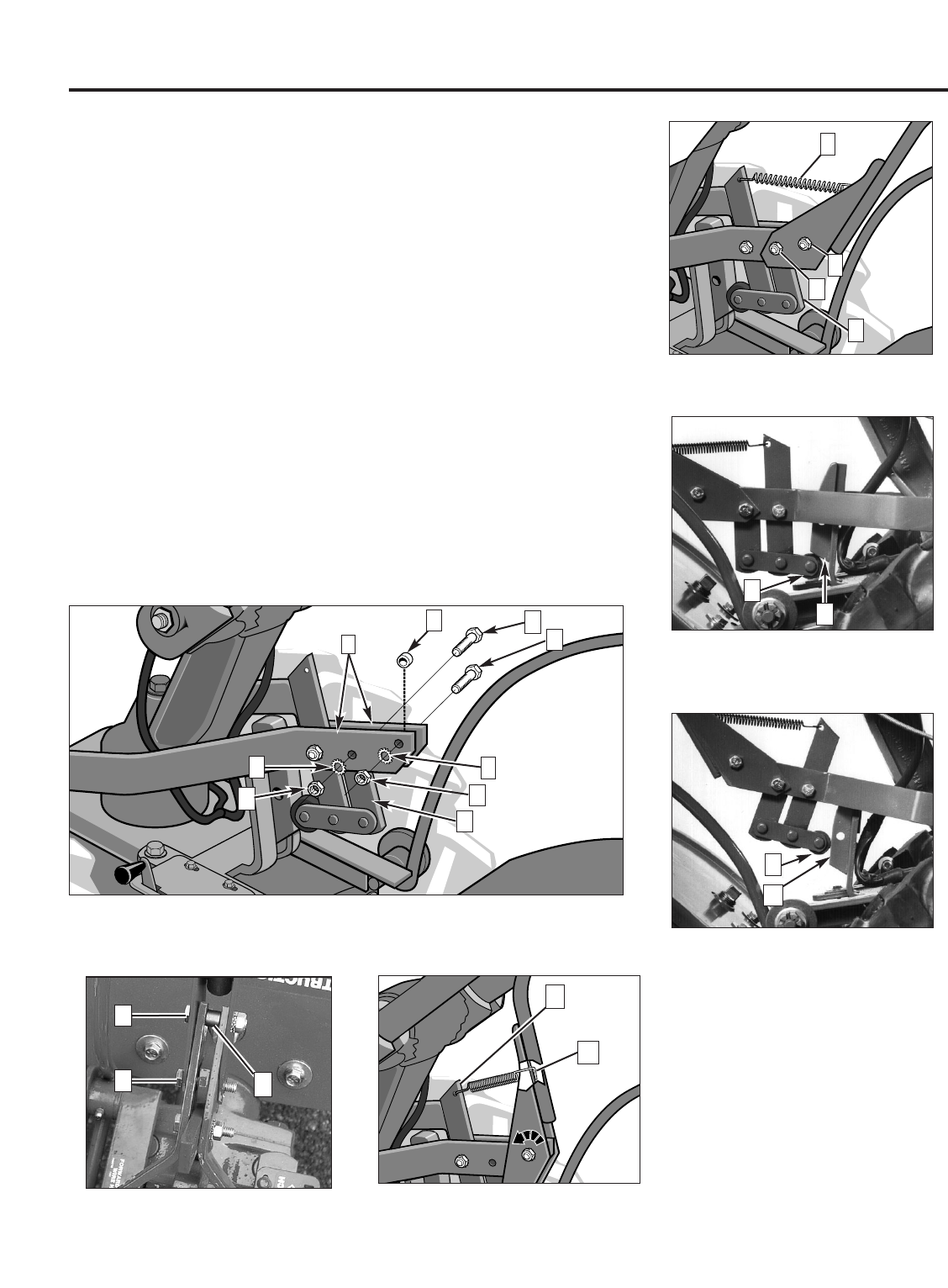

Figure 2-6: Illustration shows the yoke plates (H), nuts, washers, and

screws (A, E, B, F, D, G), bushing (C), and long and short links (I, J).

Figure 2-7: Drive Lever assembly.

Figure 2-11: Neutral position; roller

(T) rests against middle area of the

adjustment block (U).

A

I

B

C

H

D

E

F

G

Figure 2-10 Forward position; roller

(T) rests under the adjustment

block (U).

U

T

T

U

Figure 2-8: Clutch pawl spring. Tilt

Wheels\Tines\PTO Lever fully

forward before installing spring.

N

M

Section 2: Assembly

Figure 2-9: Fully assembled

Wheels/Tines/PTO Lever assembly.

K

J

L

Q

R

S

STEP 6: Check Gear Oil Levels

Your tiller has two separate transmis-

sions: one for the Power Unit (Figure 2-

12), the other for the Tine Attachment

(Figure 2-13). Both transmissions were

filled at the factory with SAE #85W–140

weight gear oil (with an A.P.I rating of

GL-4). Check level in both transmis-

sions to verify that they are still correct.

See Section 5,

Transmission Gear Oil

Maintenance for complete information

on how to check and fill the transmis-

sions.

P

Remove the temporary screw (J, Figure

2-7) from the forward holes and move the

Wheels/Tines/PTO Lever fully forward.

Install the wider hook end of the clutch

pawl spring (M, Figure 2-8) down into the

small hole at the end of the handle. Use

pliers to insert the other end into the hole

in the long link bar (N).

NOTE: Do not bend or over stretch the

spring while installing.

6. Pull the Wheels/Tines/PTO Lever back

to align the forward most holes (Q, Figure

2-9) in the yoke plate with the holes in the

lever plates. Also align the bushing that is

inside the short link bar (P). Install the

screw, star washer, and nut, then tighten

securely.

Securely tighten all other hardware (Q, R,

Figure 2-9). Also ensure that the spring

(S) is properly seated at both ends.

Completed assembly should appear as

illustrated in Figure 2-9.

7. Test the operation of the

Wheels/Tines/PTO Lever. Push the lever

down until it engages in the Forward

position. The clutch roller (T, Figure 2-

10) must rest beneath the adjustment

block (U). Next, move the lever up to the

Neutral position. The clutch roller (T,

Figure 2-11) should rest on the face of the

adjustment block (U). To test Reverse, lift

and hold the lever all the way up in

Reverse position, then let it go. The lever

should automatically return to the Neutral

position (Figure 2-11). If not, do not use

the tiller. See your local authorized dealer

or call the Factory Technical Service

Department for instructions.