NOTE: The inner reel must be totally

dry before reinstalling it into

the outer spool. Do not

lubricate the inner reel or

outer spool assembly.

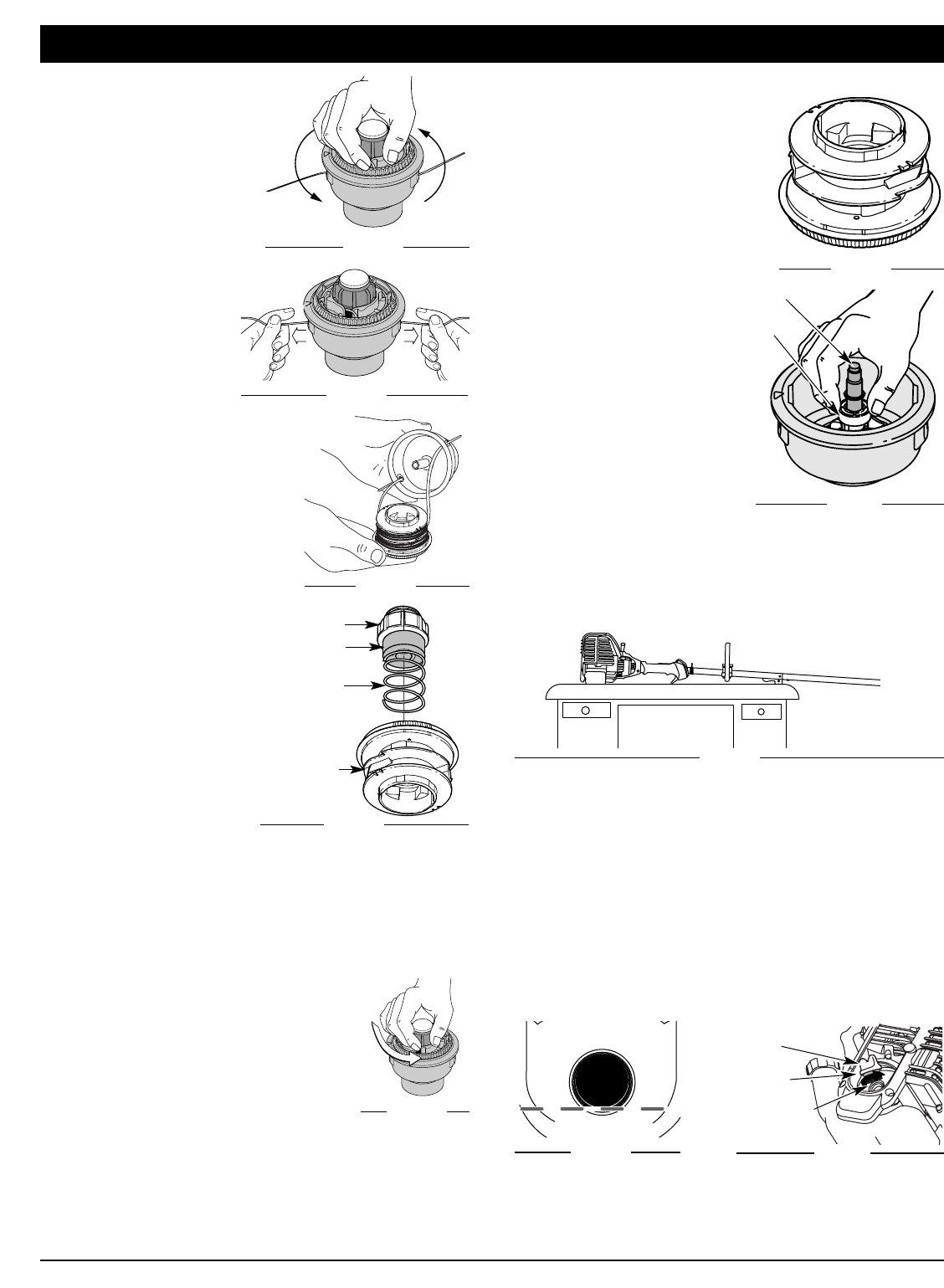

6. Place the inner reel into the

outer spool.

7. Place the bump knob, spring

and foam seal into the inner reel

(Fig. 27).

8. Press the bump knob down and

tighten clockwise.

9. Install new line as

described in Line

Installation for the

SpeedSpool

®

.

11

MAINTENANCE AND REPAIR INSTRUCTIONS

9. If winding the line becomes

difficult or if the line jams,

pull the ends of the line from

the spool (Fig. 24). Continue

winding the inner reel

counterclockwise until

approximately 6 inches of

line is left.

INSTALLING A PRE-WOUND

REEL

1. T

urn the bump knob

counterclockwise and

remove the bump knob,

spring and foam seal

(Figs. 28 & 27).

2. Pull the old inner reel

with existing line from

the outer spool.

3. Insert the ends of the

prewound inner reel line

into the outer spool eyelets (Fig. 26).

Push the new inner reel, arrow side

up, into the outer spool.

4. H

old the inner reel in place and

install the bump knob, spring and

foam seal (Fig. 27). Press down and

turn the bump knob clockwise.

Grasp the ends and pull firmly to

release the line from the holding

slots in the inner reel.

Releasing the Inner Reel

If the SpeedSpool

®

does not

release line correctly, pull the

ends of the line firmly from the

spool (Fig. 25). If this does not

the release line, follow the

Cleaning the SpeedSpool

®

instructions.

NOTE: Do not wind the inner

reel before installing

the second piece of

line.

CLEANING THE

SPEEDSPOOL

®

Cleaning the SpeedSpool

®

may

be necessary if:

• A jammed or excessive line must be removed

• The SpeedSpool

®

becomes difficult to wind or does not

operate correctly when bumping the head on the ground

1. Hold the outer spool, and unscrew the bump knob

counterclockwise (Fig. 28).

2. Pull out the bump knob, spring and foam

seal (Fig. 27).

3. P

ull the inner reel with existing line from the

outer spool (Fig. 29).

4. Remove any existing line from the inner

reel before cleaning. Remove any debris

or grass from the knob, spring, inner reel

and foam seal. Wash the inner reel with

warm soapy water (Fig. 29).

5. Clean the shaft and the inner surface of the outer spool. To

clean the shaft underneath the plunger, press down on the

plunger (Fig. 30). Remove any dirt or debris from the shaft.

Fig. 24

Fig. 25

Bump Knob

Foam Seal

Spring

Inner Reel

Fig. 27

Fig. 26

Fig. 28

Fig. 29

Inner Reel

CHECKING THE OIL LEVEL

The importance of checking

and maintaining the proper oil

level in the crankcase cannot

be overemphasized. Check oil

before each use:

1. Stop the engine and allow oil to drain into the crankcase.

2. Place the engine on a flat, level surface with the cutting

head shield hanging off a work bench or table to get a

proper oil level reading (Fig. 31).

3. Keep dirt, grass clippings and other debris out of the engine.

Clean the area around the dipstick before removing it.

4. Remove the oil fill plug.

5. Look into the oil fill hole, use a flashlight if needed. The oil

should be just touching the inner most thread (Fig. 32).

6. If the oil level is not touching the inner most thread on the

oil fill hole, add a small amount of oil to the oil fill hole and

recheck (Fig. 32). Repeat this procedure until the oil level

reaches the inner most thread on the oil fill hole.

NOTE: Do not overfill the unit.

NOTE: Make sure the O-ring is in place on the oil fill plug when

checking and changing the oil (Fig. 33).

Fig. 31

Oil Fill Plug

Oil Fill Hole

O-Ring

MaxOil Fill Line

Fig. 33

Fig. 32

Shaft

Plunger

Fig. 30