SECTION5: MAINTENANCE

,_ WARNING: Before

inspecting, cleaningor servicing

the machine,shut off engine,

wait for all moving partsto come

to a completestop, disconnect

spark plug wire andmove wire

awayfrom spark plug. Remove

ignition key on electricStart

models.

Failuretofollow these

instructions canresult in serious

personalinjury or property

damage.

MAINTENANCE SCHEDULE

PROCEDURE NOTES

Checkmotoroil level

Cleanengine

Checkdrivebelttension

Checknutsandbolts

Changemotoroil

Lubricatetiller

Serviceengineaircleanersystem

Checkgearoil levelintransmission

Checktinesfor wear

Checkair pressureintires

(if unithaspneumatictires)

Servicesparkplug

2,3

2,7

1,4

i, 4

4,6,9

4

1,5

5

NOTES

I - Checkafter first 2 hours of break-in operation.

2 - eefora eachuse.

3 - Every5 operatinghours.

4, Every!Ooperatinghoura.

5 - Every30 operatinghours.

6 - Changemore frequently industy Conditions.

7 - See EngineOwner'sManual forservice

recommedations.

8- Whichevertimeintervaloccursfirst.

g - Changeaftergrst2hoursofbrsak-in

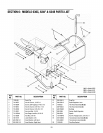

TILLERLUBRICATION

After every 10 Operatinghours,oil or

greasethe lubrication points shown in

Figure5-1 and described belOW,

Usecleanlubricating oil (#30weight motor

oil is suitable) and cleangeneralpurpose

grease(greasecontaininga metallubricant

is preferred, if available).

• Removethewheels,cleanthewheelshaft

(A, Fig.5-1) andapply a thin coating of

greaseto the wheelshaft,

• Greasethe back,front and sides ofthe

depth regulator lever (B,Fig. 5-1).

• Removethe tines andcleanthetine shaft

(C, Fig.5-1). Use a file or sandpaperto

gently remove anyrust, burrs or rough

spots (especiallyaround holes in shaft).

Applygreaseto endsof shaft beforeinstall-

If a cover is leaking,checkfor loose

screws. If the screws aretight, a new

gasket or oi!seal may be required.

If the leakisfrom around a shaftand oil

seal, the oil seal probably needsto be

replaced. Seeyour authorizeddealeror

contact thefactory for serviceor advice.

IMPORTANT:Neveroperatethe tiller if

the transmission is low on oil. Check

the oil levelafter every30 hours of

operationand wheneverthere isany oil

leakage.

CHECKHARDWARE

Checkfor looseor missing hardwareaf-

ter every 10 operatinghoursand tighten

or replace(as needed)beforereusing

tiller

Besureto checkthe screws underneath

ing tines, thetiller hoodthat securethetransmis-

• Oilthe threads onthe handlebarheight sioncoverandthe DepthRegulatorLever

adjustment screws andthe handlebar to thetransmission.

attaching screws (D, Fig.5-1). CHECK TIRE PRESSURE

(Models with pneumatic tires)

airOhecktheairpressureinbotht,reS.pressureshou,dbebetween15ps,The

B_ and 20 PSI(pounds per squareinch).

Keepbothtires equally inflatedto help

prevent machinefrom pulling to one

side.

TRANSMISSION

GEAROILSERVICE

Figure5.1

CHECKFOROILLEAKS

Beforeeachuse,checkthetiller for signs of

an oil leak-- usually adirty, oily accumu-

lationeither on the unit or on thefloor.

A little seepagearound a cover or anoil

sealis usually not a causefor alarm. How-

ever,if the oil drips overnight, then imme-

diateattention is needed. Ignoring an oil

leakcanresult in severe transmission

Checkthetransmission gear oil level

after every 30 hoursof operationor

wheneveryou noticeany oil leak. Oper-

ating thetiller whenthe transmission is

low on oil can result in severedamage.

A. ToChecktheTransmission

GearOil Level:

1. Checkthe gear oil levelwhenthe

transmission is cool. Gearoil will

expandin warm operatingtemperatures

andthis expansionwill providean incor-

rect oil levelreading.

2. With thetiller onlevelground, pullthe

Depth RegulatorLeverall the way up.

3. Removethe oil fill plug (A, Fig.5-2)

from thetransmission housingand look

damage] insidethe oil fill holeto locatethe main

drive shaft situated belowthe hole.

17