16 Section 5: Maintenance

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

come to a stop, disconnect spark plug wire and move wire away from spark plug. Remove key on

electric start models.

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING

CHANGING TRIMMER LINES

When trimmer lines wear, it takes longer

to complete mowing and trimming pro-

jects. A good rule of thumb is to change

the lines when they reach half their orig-

inal length.

Use the extra-heavy duty (.155" diameter)

line when cutting thick, tough growth.

Use thinner (.130" diameter) line for less

demanding conditions and for use near

trees or shrubs to help prevent girdling

(cutting of bark).

To Change Trimmer Lines:

1. Stop engine, allow all parts to stop

moving and then disconnect the spark

plug wire. Remove the ignition key on

electric start models. DO NOT touch the

metal wear cup on the bottom of the

spindle head—it may be hot.

NOTE: The two line holders on the

trimmer head are permanently secured.

Do not attempt to remove the line

holders.

2. If necessary, you may tip the unit

back slightly when changing lines. How-

ever, do not tip the unit all the way back

as motor oil may flow to the exhaust area

and the engine may smoke for several

seconds when started.

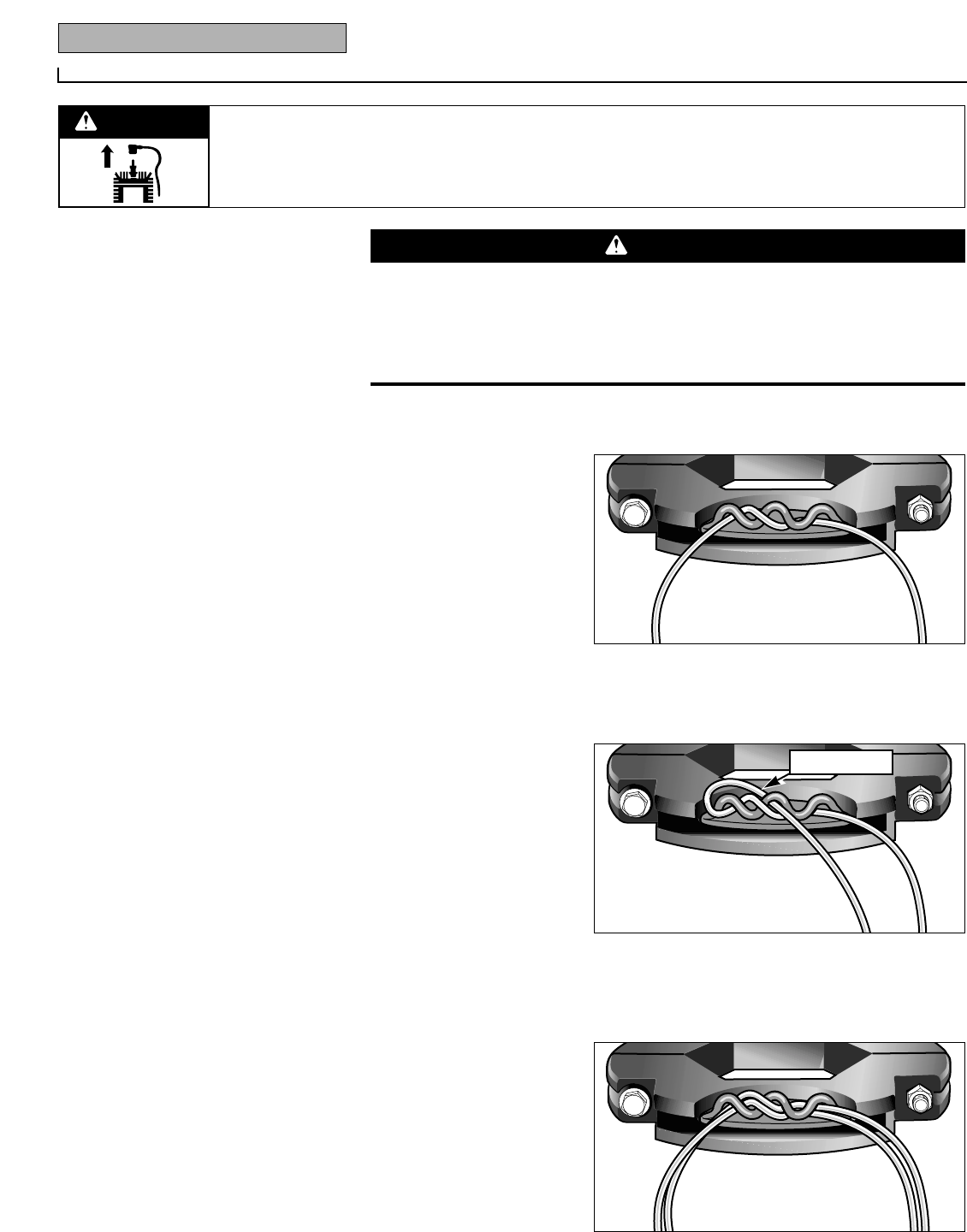

3. Three different line installation pat-

terns are available, as shown in Figures

5-10, 5-11 and 5-12.

4. Feed the line through the loops of the

line holder as shown.

• An equal amount of line should project

out from each side of the line holder,

creating an overall 22" wide cutting

swath.

• You may offset both trimmer lines

somewhat to increase the cutting swath

up to 25" wide. However, DO NOT

offset the line so that the overall cutting

swath is greater than 25". See Warning

statement at right.

• Whether replacing one or both lines,

they must both be .130" or .155" in

diameter.

Figure 5-10: Use this single

line, easy-loop pattern for all but

the more difficult cutting condi-

tions.

Figure 5-12: For more difficult

cutting conditions, use two of the

thicker gauge (.155" diameter)

lines in each line holder. Follow

the installation pattern shown in

Figure 5-10.

Figure 5-11: If the lines should

loosen while trimming (espe-

cially in more difficult condi-

tions), add a simple reverse

loop. Note that this pattern will

result in a slightly narrower

overall cutting swath.

Offsetting the trimmer lines causes the lines to rotate faster than when they project

an equal length on each side. This increases the chance of loose materials being

dislodged and propelled at high speeds.

Failure of the operator to wear safety goggles and appropriate clothing and to keep

bystanders away can result in severe personal injury or property damage.

WARNING

Reverse Loop