9

To Empty Bag

• Depress the plunger on the drawstring and slide the

plunger out to loosen bag from discharge chute

opening.

• Empty bag and reattach to the discharge chute

opening. Depress the plunger on the drawstring

and pull on the drawstring until the bag is tight

around the chute opening.

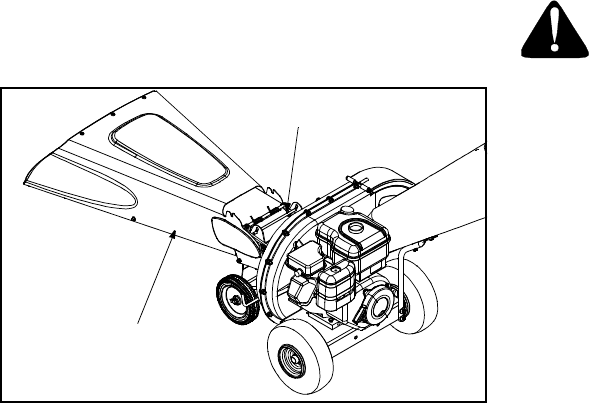

Lowering the Hopper Assembly

The machine can be operated with the hopper assemby

in either the raised or lowered positions. With the

hopper assemby pivoted down, leaves and other small

loose debris can be raked directly into it. To reposition

the hopper assembly, proceed as follows:

• With one hand grasp the handle at the top of the

hopper assembly and lift slightly.

• With the other hand pull out on the release rod and

lower the hopper assembly to the ground.

See Figure 7.

Figure 7

Using the Chipper Shredder

Your new chipper shredder has two feed openings.

Refer to Figure 6.

Hopper Assembly:

For shredding light yard waste, twigs and branches

up to ½-inch in diameter .

Chipper Chute:

for branches up to 3” in diameter.

IMPORTANT:

Do NOT insert branches larger than ½-

inch in diameter into the hopper assembly. Doing so

may result in serious damage to the machine.

Shredding

The hopper assemby is intended for small, light

debris such as leaves, pine needles, garden waste,

twigs and branches less than ½” in diameter.

Material fed into the hopper assemby passes

through both a shredder blade, which chops it into

small pieces and flail fingers, where the material is

shredded and broken up into even smaller pieces.

Chipping

The chipper chute is intended primarily for small

branches and limbs up to 3” in diameter. Branches

fed into the chipper chute, are chipped by a pair of

blades mounted to the backside of the unit’s

impeller.

Operating tips

WARNING: The operation of any chipper

shredder can result in foreign objects being

thrown into the eyes, which can damage your

eyes severely. Always wear the safety

glasses provided with this unit or eye shields

before chipping or shredding and while

performing any adjustments or repairs.

• Use a pruner or saw to trim smaller branches off the

main branch being fed. This will allow branches to

feed more easily into the chipper chute.

• Feed “bushy” material, such as the ends of tree

limbs with smaller branches coming off a main

branch, with the “grain” (larger diameter end first).

• When chipping branches, once the branch is

chipped down to the point it is completely inside the

chipper chute, let go of it and it will self-feed the rest

of the way.

• Avoid feeding fibrous plants (i.e. tomato vines, etc.)

into the hopper assembly until they are thoroughly

dried out.

• If feeding wet leaves, feed them in small clumps to

avoid clogging the discharge opening.

• Keep the chipper blades sharp. Difficulty feeding

material and increased vibration when feeding are

signs the chipper blades need to be sharpened or

replaced.

• Do not shut the engine off while material is still in

the chipper chute or hopper assembly. Any

unprocessed material may jam the machine and

interfere with re-starting the engine.

IMPORTANT:

The flail screen is located inside the

housing in the discharge area. If the flail screen

becomes clogged, remove and clean as instructed in

SECTION 5: MAINTAINING YOUR CHIPPER SHREDDER.

Release Rod

Hopper Assembly