18 Section 5: Maintenance

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

come to a complete stop, disconnect spark plug wire and move wire away from spark plug.

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING

4. The gear oil level is correct if the gear

oil is approximately halfway up the side of

the main drive shaft.

5. If the gear oil level is low, add gear oil

as described next. If the gear oil level is

okay, securely replace the oil fill plug.

IMPORTANT: Do not operate the tiller if

the gear oil level is low. Doing so will

result in severe damage to the transmis-

sion components.

6. If adding only a few ounces of gear oil,

use API rated GL-4 or GL-5 gear oil having

a viscosity of SAE 140, SAE 85W-140 or

SAE 80W-90. If refilling an empty trans-

mission, use only GL-4 gear oil having a

viscosity of SAE 85W-140 or SAE 140.

IMPORTANT: Do not use automatic trans-

mission fluid or motor oil in the transmis-

sion.

7. While checking frequently to avoid

overfilling, slowly add gear oil into the oil

fill hole until it reaches the halfway point

on the drive shaft.

8. Securely replace the oil fill plug.

B. To Drain the Transmission Gear Oil:

The transmission gear oil does not need to

be changed unless it has been contami-

nated with dirt, sand or metal particles.

1. Drain gasoline from the fuel tank or run

the engine until the fuel tank is empty. See

“DANGER” statement below.

2. Drain the oil from the engine.

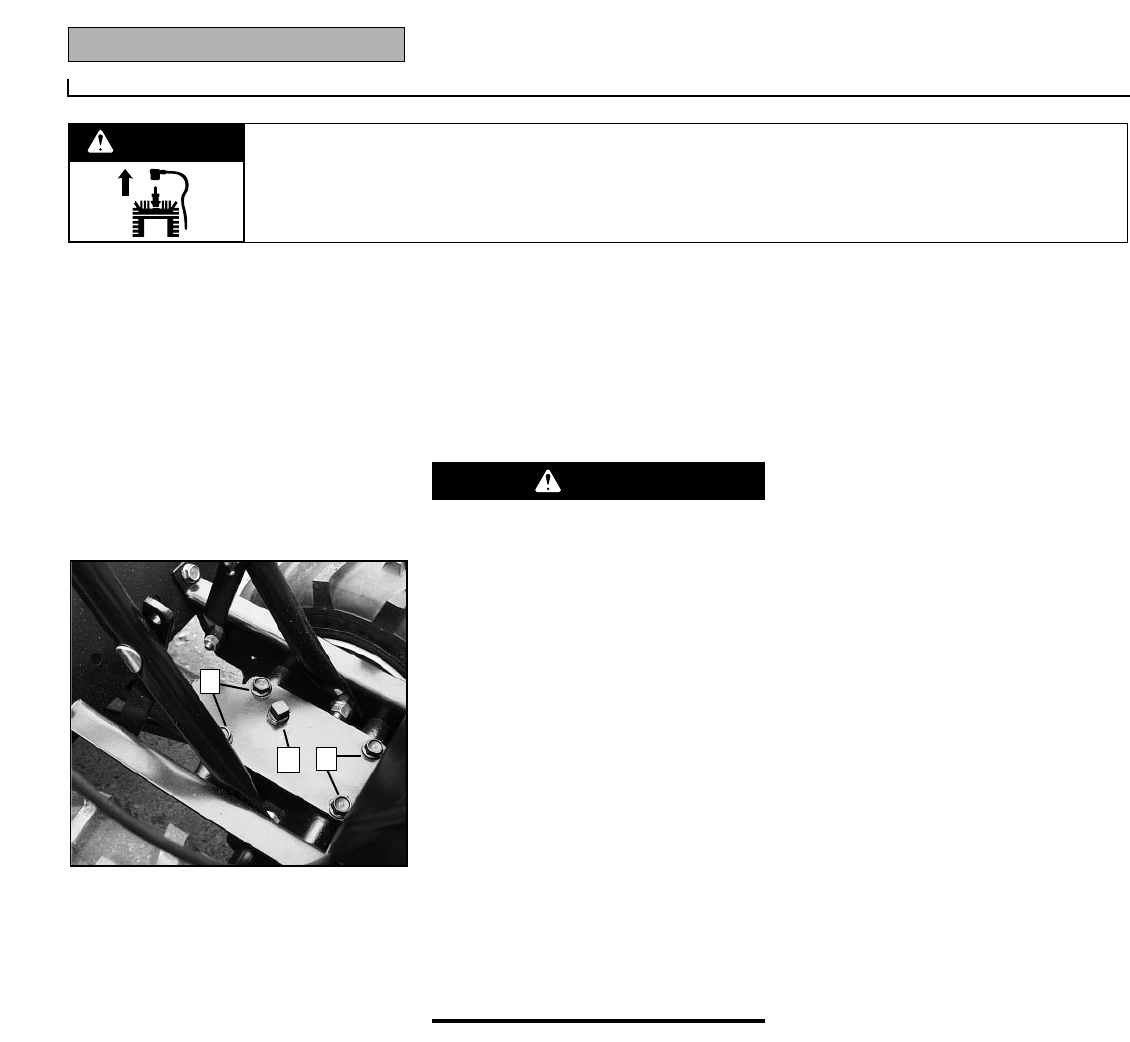

3. Remove four screws (B, Figure 5-2) and

remove transmission cover and gasket.

4. Remove the left-side wheel.

5. Tilt the left-side wheel shaft into a drain

pan and allow the gear oil to drain through

the top of the transmission.

6. Reinstall the wheel.

7. Install a new gasket (do not reuse old

gasket) and reinstall the transmission

cover.

8. Refill the transmission using GL-4 gear

oil (SAE 85W-140 or SAE 140).

9. Refill the engine with motor oil and

replenish the fuel tank with gasoline.

BOLO TINES

The bolo tines will wear with use and

should be inspected at the beginning of

each tilling season and after every 30

operating hours. The tines can be

replaced either individually or as a com-

plete set. See the Parts List pages for tine

identification and part numbers.

A. Tine Inspection:

With use, the tines will become shorter,

narrower and pointed. Badly worn tines

will result in a loss of tilling depth, and

reduced effectiveness when chopping up

and turning under organic matter.

B. Removing/Installing a Single Tine:

1. With the engine shut off and the spark

plug wire disconnected, remove the two

screws (A, Figure 5-3) and locknuts (B)

that attach a single tine to a tine holder. If

needed, use penetrating oil on the nuts.

2. When installing a single tine, be sure to

position it so that its cutting edge (sharp)

will enter the soil first as the tiller moves

forward.

C. Removing/Installing a Tine Assembly:

1. A tine assembly consists of eight tines

mounted on a tine holder.

2. If removing both tine assemblies, mark

them “left” and “right” before removal.

Remove the screw (C, Figure 5-3) and

locknut (D) that secure the tine assembly

to the tine shaft. If necessary, use a

rubber mallet to tap the tine assembly out-

ward off the shaft.

3. Before reinstalling the tine assembly,

inspect the tine shaft for rust, rough spots

or burrs. Lightly file or sand, as needed.

Apply a thin coat of grease to the shaft.

4. Install each tine assembly so that the

cutting (sharp) edge of the tines will enter

the soil first when the tiller moves

forward. Secure the tine assembly to the

tine shaft using the screw and locknut

previously removed.

Gasoline is highly flammable and its

vapors are explosive. Follow these

safety practices to prevent personal

injury or property damage from fire or

explosion.

• Allow the engine and muffler to cool

for at least two minutes before

draining the tiller’s gasoline tank.

• Do not allow open flames, sparks,

matches or smoking in the area.

• Wipe away spills and push tiller away

from spilled fuel.

• Use only an approved fuel container

and store it safely out of the reach of

children.

• Do not store gasoline in an area where

its vapors could reach an open flame

or spark, or where ignition sources are

present (such as hot water and space

heaters, furnaces, clothes dryers,

stoves, electric motors, etc.)

DANGER

Figure 5-2: Remove oil fill plug (A) to check

gear oil level and to add gear oil. Remove

four cover screws (B) to drain gear oil.

B

BA