Arc Adjustment Procedure (Part-circle Models) ________________________________________

The 860S and 880S part-circle models have an adjustable watering arc from 30°–330° and are factory preset at 180°. The left side of

the arc, located at the end of counterclockwise rotation, is non-adjustable (fixed). Therefore, all arc adjustments, whether increasing

or decreasing, will change the right side of the arc, located at the end of clockwise rotation.

Although the sprinkler arc can be adjusted dry (sprinkler shut off), the best results are obtained during operation. The tools required

for this procedure include a phillips screwdriver and an arc adjustment tool P/N 995-82 (or a 3/32" x 6" hex wrench).

1. Operate the sprinkler. See

WARNING above.

Note: During this procedure, water will discharge

continuously from the threaded shaft.

2. To check the current arc setting, rotate the cap by hand

in the direction of current travel to the end of the arc.

Immediately rotate the cap in the reverse direction to

the opposite end of the arc.

3. Rotate the cap to the left side of the arc. If only a slight

adjustment (one-eighth of a turn or less) is required to

align the spray with the left watering border, turn the

sprinkler body. If more than one-eighth turn is required,

remove the sprinkler drive assembly and reposition it in

the body to achieve the proper alignment. Refer to the

service procedures on page 9 for disassembly instructions.

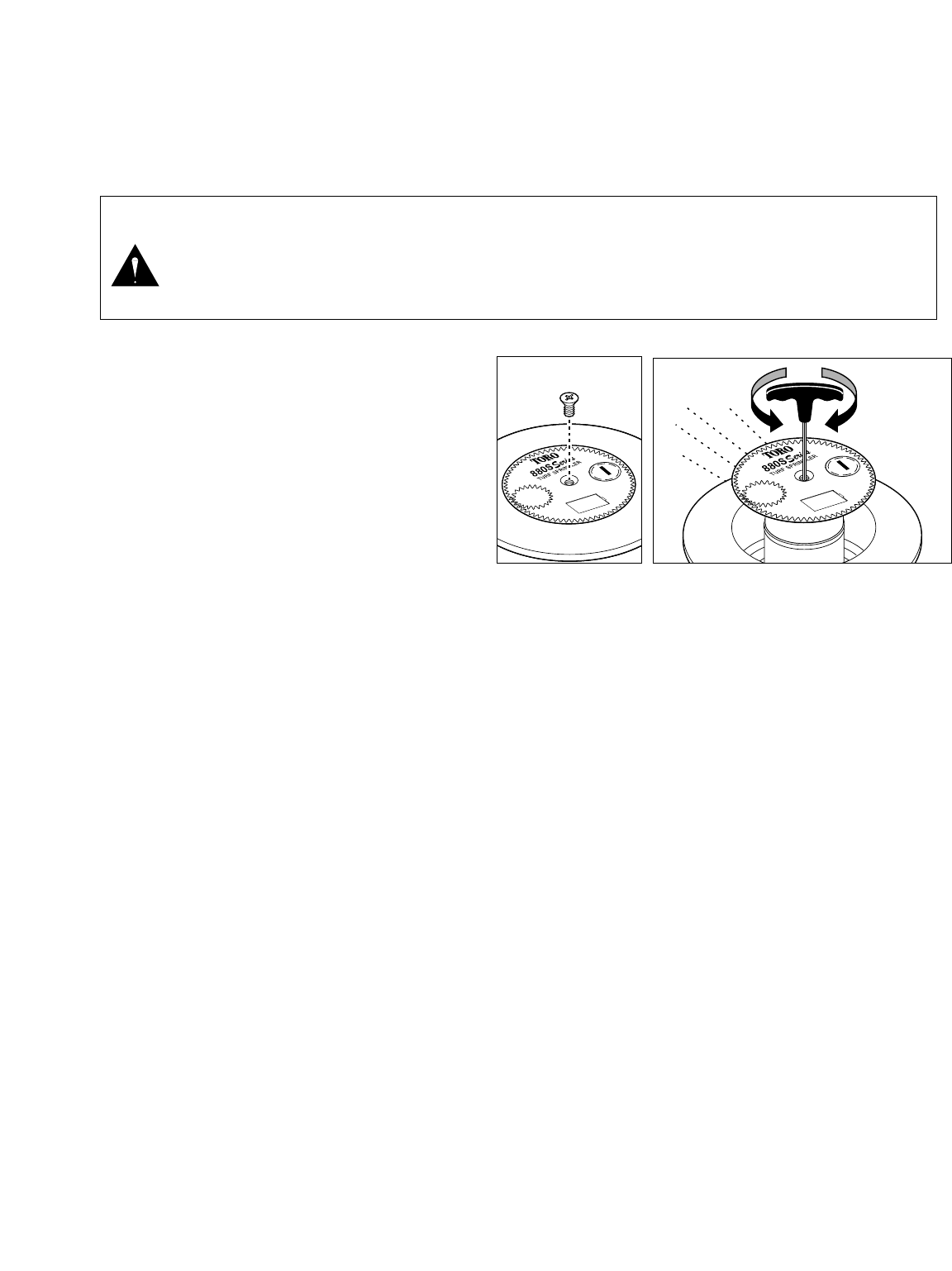

4. To adjust the arc, remove the phillips head screw from the center of the cap. See

Figure 3.

5. Insert arc adjustment tool (P/N 995-82) or a 3/32" x 6" hex wrench into threaded shaft. Turn the tool slowly

counterclockwise

to decrease the arc or clockwise to increase the arc as shown in Figure 4.

Note: Each “click” equals 1° of arc change. One complete revolution of the hex wrench results in a 75° change.

6. Repeat steps 2 and 5 as necessary, making small adjustments until exact arc is set.

7. Install cap screw when arc adjustment is completed.

Pilot Valve Operation (Electric Models Only) _______________________________________________

The main function of the pilot valve is to control the operation of the main valve located in the base of the sprinkler body. The main

valve is operated by the release of water metered through the pilot valve when it is activated either manually at the sprinkler or by the

irrigation system controller.

Another important function of the pilot valve is to regulate the water pressure to the sprinkler nozzle. Pressure regulation

compensates for large variations within the system and maintains a constant pressure for optimum sprinkler operation. The pilot

valve is factory set to regulate one of four pressure levels 50 psi (3.4 bar), 65 psi (4.5 bar), 80 psi (5.5 bar) or 100 PSI (6.9 bar).

The sprinkler operation mode is set using a Toro Selector Tool (P/N 995-15) inserted through the body flange onto the pilot valve

D-shaped selector cam. The "AUTO" mode permits automatic operation from the system controller. The "ON" mode opens the main

valve for manual operation and "OFF" mode prevents the main valve from opening.

Troubleshooting ___________________________________________________________________

Pilot Valve

PROBLEM POSSIBLE CAUSE – CORRECTIVE ACTION

SPRINKLER WILL (a) No 24 VAC to coil assembly. (Electric Models)

NOT TURN ON – Measure voltage with a Digital Volt Meter (DVM). Check wiring and controller program.

– Refer to Controller Operating Instructions.

(b) Selector cam in "OFF" position.

– Set to "AUTO" position.

(c) Debris in pilot valve assembly.

– Disassemble and remove all debris. (See Servicing Pilot Valve page 11.)

(d) Insufficient pressure in controller supply line and/or sprinkler control tube. (N.C. Models)

– Check pressure.

(continued)

5

TO

Figure 3

Figure 4

Increase

Decrease

WARNING

NEVER STAND OR LEAN OVER THE SPRINKLER WHILE THE IRRIGATION SYSTEM IS BEING FILLED,

DURING MANUAL OR AUTOMATIC OPERATION OR WHEN PERFORMING SPRINKLER SERVICE

PROCEDURES. DIRECT CONTACT WITH IRRIGATION SPRAY, A FAILED OR IMPROPERLY INSTALLED

SPRINKLER CONNECTION OR SPRINKLER COMPONENTS FORCIBLY EJECTED UPWARD UNDER

PRESSURE CAN CAUSE SERIOUS INJURY.