Mitsubishi 3G83 Carburetor Cleaning Instructions

Remove the carburetor from the machine. Disassemble the carburetor and thoroughly clean out

the Fuel Inlet System including the Fuel Inlet Chamber, Inlet Screen, Main Jet Holder Assembly,

Float Chamber Cover Assembly, Float, Needle Valve and Seat. Clean the remainder of the

carburetor body in a small container using clean, fresh solvent or carburetor cleaner. Used

solvent can have debris that can enter the small passages of the carburetor. It is not

recommended to use compressed air and force solvent into carburetor passages. It is

recommended by Mikuni to use a suction action to pull debris out of the carburetor passages.

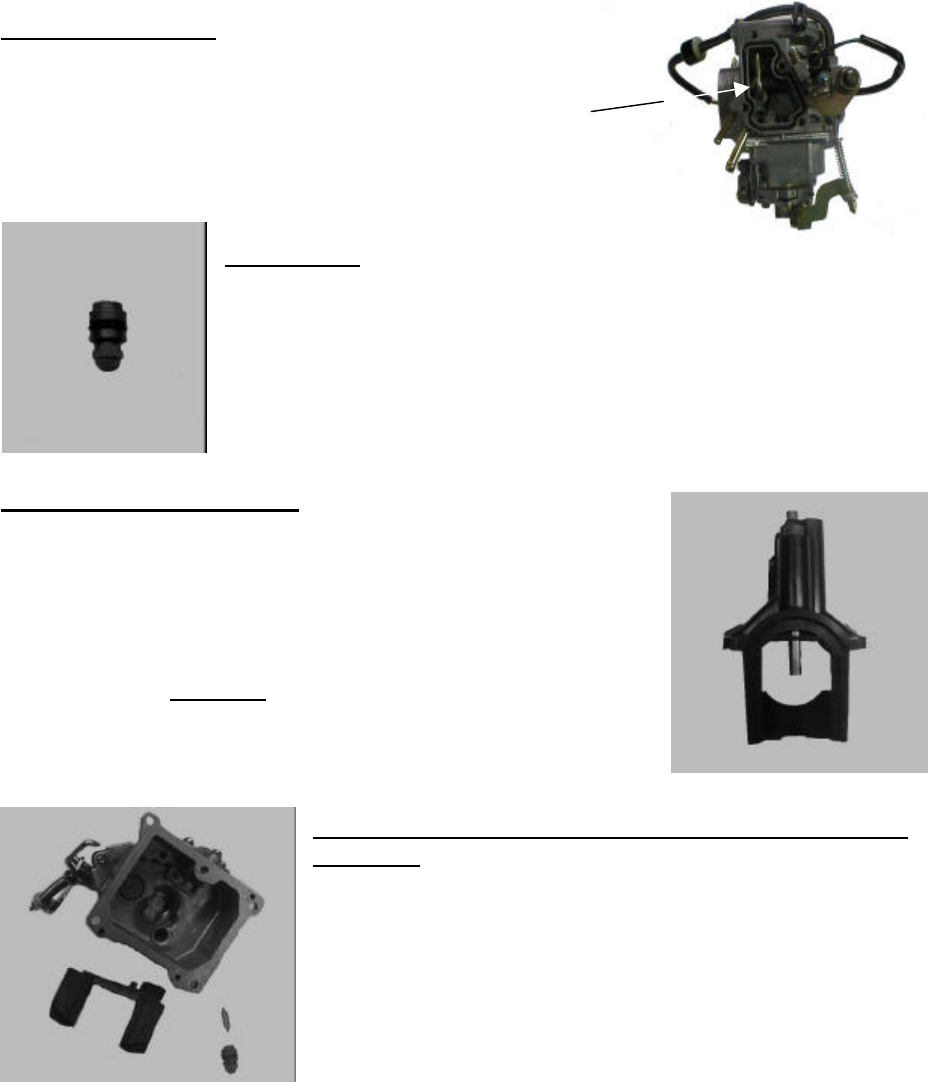

Fuel Inlet Chamber

The fuel system inlet line and return line is located on the

side of the carburetor. Remove the inlet cover plate.

Thoroughly clean this chamber using fresh solvent and

reinstall cover plate.

Inlet Screen

The Inlet Screen is mounted on the bottom of the Needle Valve Seat.

Rinse the Inlet Screen in fresh solvent and clean out by blowing

compressed air through the screen in the opposite direction of fuel flow.

Doing so will dislodge any debris buildup. Re-rinse Needle Valve Seat in

clean solvent and re-install in carburetor. If the screen is damaged, or

cannot be cleaned, replace by installing Needle Valve Kit ((92-5140)

Main Jet Holder Assembly

The Main Jet Holder Assembly houses the Main Jet, Pilot Jet and

Power Jet and is located in the float chamber assembly. Remove

jets from holder assembly and clean using fresh solvent. If the jets

are corroded or cannot be cleaned using solvent, replace them by

installing Main Jet Holder Assembly (92-5132).

IMPORTANT: DO NOT use a wire to clean out any jets or

passages within the carburetor. A wire may damage the jet and

prevent proper engine operation.

Float Chamber Cover Assembly, Float, Needle Valve

and Seat.

Remove the Float Chamber Cover Assembly, Float Assembly,

and Needle Valve and clean using fresh solvent. If the entire

Float Chamber Cover, Float Assembly, and Needle Valve

Assembly cannot be cleaned using solvent, replace the parts by

installing Float Chamber Assembly (92-5144), Needle Valve Kit

(92-5140), Float & Pin Kit (92-5127).